Method for reducing calcium ions and magnesium ions in electrolytic manganese qualified solution

A technology for electrolytic manganese qualified solution, calcium and magnesium ions, applied in the direction of electrolysis process, electrolysis components, process efficiency improvement, etc., to avoid low production efficiency, easy large-scale production, and low production and operation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

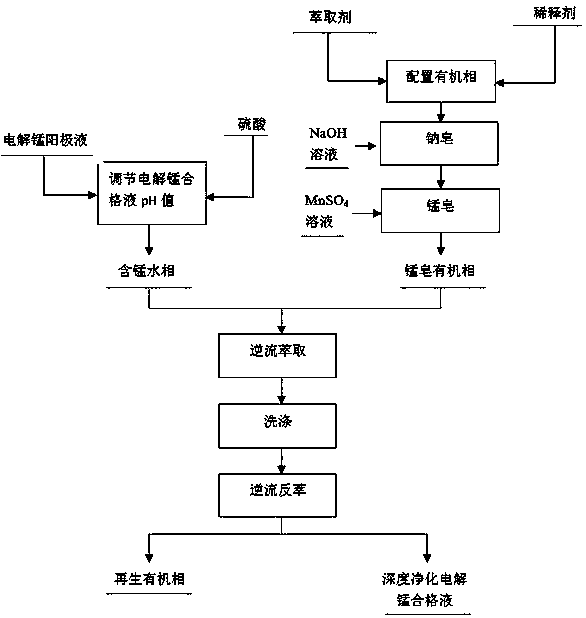

[0024] Such as figure 1 As shown, the method for reducing calcium and magnesium ions in the electrolytic manganese qualified solution, its specific steps include:

[0025] Step 1: Step 1.1, adjust the pH value of the qualified electrolytic manganese solution: adjust the pH value of the qualified electrolytic manganese solution to 2 with 2mol / L sulfuric acid solution, and add the electrolytic manganese anolyte (that is, the electrolytic manganese anolyte, including Mn 2+ 15g / L, Mg 2+ 17g / L, H 2 SO 4 36g / L), the pH-adjusted electrolytic manganese qualified solution includes Mn 2+ 32g / L, Ca 2+ 800mg / L, Mg 2+ The concentration is 38g / L, (NH 4 ) 2 SO 4 130g / L;

[0026] Step 1.2, configure the extraction organic phase: the extraction organic phase is composed of extractant and 260# sulfonated kerosene, the extractant is a combined extractant of P507 and Cyanex272 with a volume ratio of 3:2, and the combined extractant is diluted to this level with 260# sulfonated kerosene ...

Embodiment 2

[0034] Such as figure 1 As shown, the method for reducing calcium and magnesium ions in the electrolytic manganese qualified solution, its specific steps include:

[0035] Step 1: Step 1.1, adjust the pH value of the qualified electrolytic manganese solution: adjust the pH value of the qualified electrolytic manganese solution to 3 with 2mol / L sulfuric acid solution, and add the electrolytic manganese anolyte (that is, the electrolytic manganese anolyte, including Mn 2+ 15g / L, Mg 2+ 17g / L, H 2 SO 4 36g / L), the pH-adjusted electrolytic manganese qualified solution includes Mn 2+ 22g / L, Ca 2+ 400mg / L, Mg 2+ The concentration is 15g / L, (NH 4 ) 2 SO 4 110g / L;

[0036] Step 1.2, configure the extraction organic phase: the extraction organic phase is composed of extractant and 260# sulfonated kerosene, the extractant is a combined extractant of P507 and Cyanex272 with a volume ratio of 3:2, and the combined extractant is diluted to this level with 260# sulfonated kerosene ...

Embodiment 3

[0044] Such as figure 1 As shown, the method for reducing calcium and magnesium ions in the electrolytic manganese qualified solution, its specific steps include:

[0045] Step 1: Step 1.1, adjust the pH value of the qualified electrolytic manganese solution: adjust the pH value of the qualified electrolytic manganese solution to 4 with 2mol / L sulfuric acid solution, and add the electrolytic manganese anolyte (that is, the electrolytic manganese anolyte, including Mn 2+ 15g / L, Mg 2+ 17g / L, H 2 SO 4 36g / L), the pH-adjusted electrolytic manganese qualified solution includes Mn 2+ 20g / L, Ca 2+ 200mg / L, Mg 2+ The concentration is 10g / L, (NH 4 ) 2 SO 4 100g / L;

[0046] Step 1.2, configure the extraction organic phase: the extraction organic phase is composed of extractant and 260# sulfonated kerosene, the extractant is a combined extractant of P507 and Cyanex272 with a volume ratio of 3:2, and the combined extractant is diluted to this level with 260# sulfonated kerosene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com