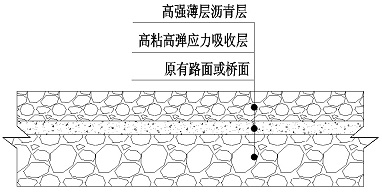

High-strength thin-layer asphalt layer to increase the structural depth of debonding and deicing materials spraying interface

A technology of structural depth and asphalt layer, applied in the field of high-strength thin-layer asphalt layer with interface structural depth, can solve the problems of endangering traffic safety, low structural depth, and should not be less than 0.3mm, etc. The effect of improving crack resistance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The high-viscosity and high-elastic stress absorbing layer is paved with high-viscosity asphalt (the specific technical indicators of high-viscosity asphalt are shown in Table 1) and 2.36-4.75mm ready-mixed gravel, which is spread by a synchronous gravel sealing vehicle, and then Compaction with rubber-tyred rollers;

[0034] High-strength thin-layer asphalt layer, high-strength thin-layer asphalt layer asphalt mixture aggregate gradation adopts UTAC-8 (gradation as shown in Table 2), asphalt adopts SBS modified asphalt, and the technical indicators meet the "Technical Specifications for Highway Asphalt Pavement Construction" (JTG F40-2004) technical requirements for polymer modified asphalt, add asphalt modifier to the asphalt mixture, the modifier is lucobit1210A produced by German Lucobit Company, and the amount of modifier is 1 / 2 of the mass of SBS modified asphalt 5%, lucobit1210A technical indicators are shown in Table 3.

[0035] Table 1 Technical indicators of ...

Embodiment 2

[0045] The high-viscosity and high-elastic stress absorbing layer is paved with high-viscosity asphalt (the specific technical indicators of high-viscosity asphalt are shown in Table 5) and 2.36-4.75mm ready-mixed gravel, which is spread by a synchronous gravel sealing vehicle, and then Compaction with rubber-tyred rollers;

[0046] The high-strength thin-layer asphalt layer is paved. The gradation of the asphalt mixture for the high-strength thin-layer asphalt layer adopts UTAC-10 (the gradation is shown in Table 6), and the asphalt adopts SBS modified asphalt. According to the technical requirements of polymer modified asphalt in the specification (JTG F40-2004), an asphalt modifier is added to the asphalt mixture. The modifier is lucobit1210A produced by Lucobit, Germany, and the amount of modifier is SBS modified asphalt. 6% of the quality, lucobit1210A technical indicators are shown in Table 3.

[0047] Table 5 Technical indicators of high-viscosity asphalt

[0048] ...

Embodiment 3

[0055] The high-viscosity and high-elastic stress absorbing layer is paved with high-viscosity asphalt (the specific technical indicators of high-viscosity asphalt are shown in Table 8) and 2.36-4.75mm ready-mixed gravel, which is spread by a synchronous gravel sealing vehicle, and then Compaction with rubber-tyred rollers;

[0056] The high-strength thin-layer asphalt layer is paved. The asphalt mixture of the high-strength thin-layer asphalt layer adopts OGFC-10 (gradation is shown in Table 9). The asphalt adopts SBS modified asphalt. According to the technical requirements of polymer modified asphalt in the specification (JTG F40-2004), an asphalt modifier is added to the asphalt mixture. The modifier is lucobit1210A produced by Lucobit, Germany, and the amount of modifier is SBS modified asphalt. 7.5% of the mass, lucobit1210A technical indicators are shown in Table 3.

[0057] Table 8 Technical indicators of high-viscosity asphalt

[0058] project unit ski...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com