RPA-LFD primer pair and probe for detecting pathogenic escherichia coli O157:H7 and application thereof

A technology of Escherichia coli and O157, applied in the field of food safety testing, can solve the problems of unfavorable on-site rapid diagnosis and accurate traceability, long testing period, expensive instruments, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

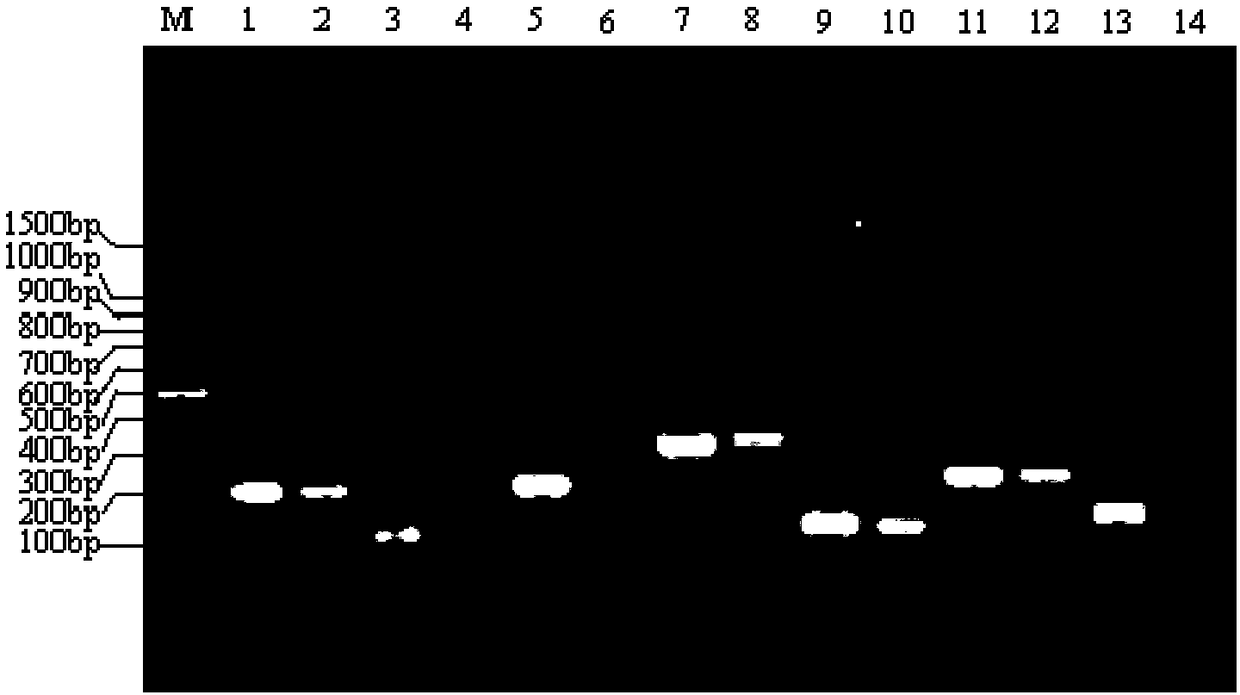

[0037] Embodiment 1, primer screening and labeling

[0038] 1. RPA primer design

[0039] According to the Escherichia coli O157:H7rfbE gene (Genbank no: S83460.1), the conserved region was analyzed by Blast, RPA primers were designed, and 4 upstream and downstream primers were designed respectively, and PCR and RPA double screening were performed on 7 different upstream and downstream primer combinations. The primer sets and their sequence information are as follows:

[0040] Group 1 (EO1)

[0041] Upstream primer EOF1:

[0042] 5'-GCCCAGTTAGAACAAGCTGATGATTTTATATCACG-3' (SEQ ID NO.1)

[0043] Downstream primer EOR1:

[0044] 5'-CCTTGTTTCGATGAGTTTTATCTGCAAGGTGATTCC-3' (SEQ ID NO.2)

[0045] Product length: 207bp

[0046] Group 2 (EO2)

[0047] Upstream primer EOF2:

[0048] 5'-CATCCATGTGATATGGAACAAATTGTAGAACTGGC-3' (SEQ ID NO.3)

[0049] Downstream primer EOR2:

[0050] 5'-CCCACATATTTACCTTTATATTTAGAACCAAAGGC-3' (SEQ ID NO.4)

[0051] Product length: 110bp

[0052] ...

Embodiment 2

[0096] Embodiment 2, RPA-LFD establishment

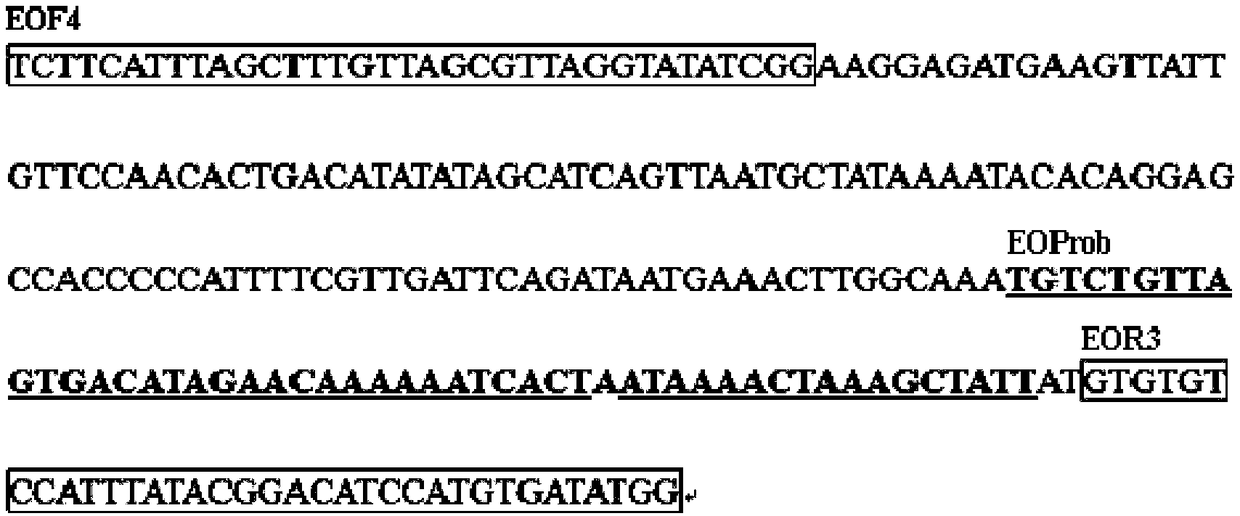

[0097] 1. Probe design

[0098]Design probe EOProb for optimal primer pair EOF4 / EOR3: 5'-FAM-TGTCTGTTAGTGACATAGAACAAAAAATCACT-THF-ATAAAACTAAAGCTATT-C3-Spacer-3'(SEQ ID NO.9)( figure 2 ).

[0099] Probe length: 49bp

[0100] Corresponding RPA product length: 233bp

[0101] 2. RPA reaction system (10μL)

[0102]

[0103]

[0104] 3. RPA reaction system amplification

[0105] Add the above reagents except magnesium acetate into a sterile centrifuge tube and mix well. Next, add the magnesium acetate solution to the inside of the cap of the sterile centrifuge tube, cap tightly and then centrifuge instantly. After centrifuging, mix well and quickly put it into a PCR instrument with the hot cap closed or incubate in a constant temperature water bath at 40°C for 10 minutes.

[0106] 4. LFD detection of RPA products

[0107] Add 2 μL of RPA product into a 96-well microplate containing 100 μL Tris-Cl Buffer (pH 8.0) and mix well...

Embodiment 3

[0108] Embodiment 3, RPA reaction condition optimization

[0109] The optimum reaction volume, optimum reaction time and optimum reaction temperature of Escherichia coli O157:H7RPA were explored. The RPA reaction volume sets 10 gradients: 5 μL, 10 μL, 15 μL, 20 μL, 25 μL, 30 μL, 35 μL, 40 μL, 45 μL and 50 μL. The content of the RPA reaction components corresponding to each reaction volume is in equal proportion to its volume. The RPA reaction was carried out in a constant temperature electric hot water bath, and the RPA products corresponding to different reaction volumes were purified and analyzed by 2% AGE and LFD. The result is as image 3 As shown, the amount of RPA amplification product was the lowest when the RPA reaction volume was 5 μL, and remained basically unchanged in the 9 gradients from 10 μL to 30 μL. The RPA reaction time sets 6 gradients: 5min, 10min, 15min, 20min, 25min and 30min. The RPA reaction system is the same except for the time. The RPA reaction wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com