High-temperature oxidation-resistant titanium alloy containing extremely low alloying elements

An alloying element, high temperature anti-oxidation technology, applied in the field of titanium alloy materials, can solve problems such as increasing production costs, increasing production processes, etc., and achieves the effect of increasing the hindering effect, improving the anti-oxidation performance, and blocking the diffusion of Ti and O ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

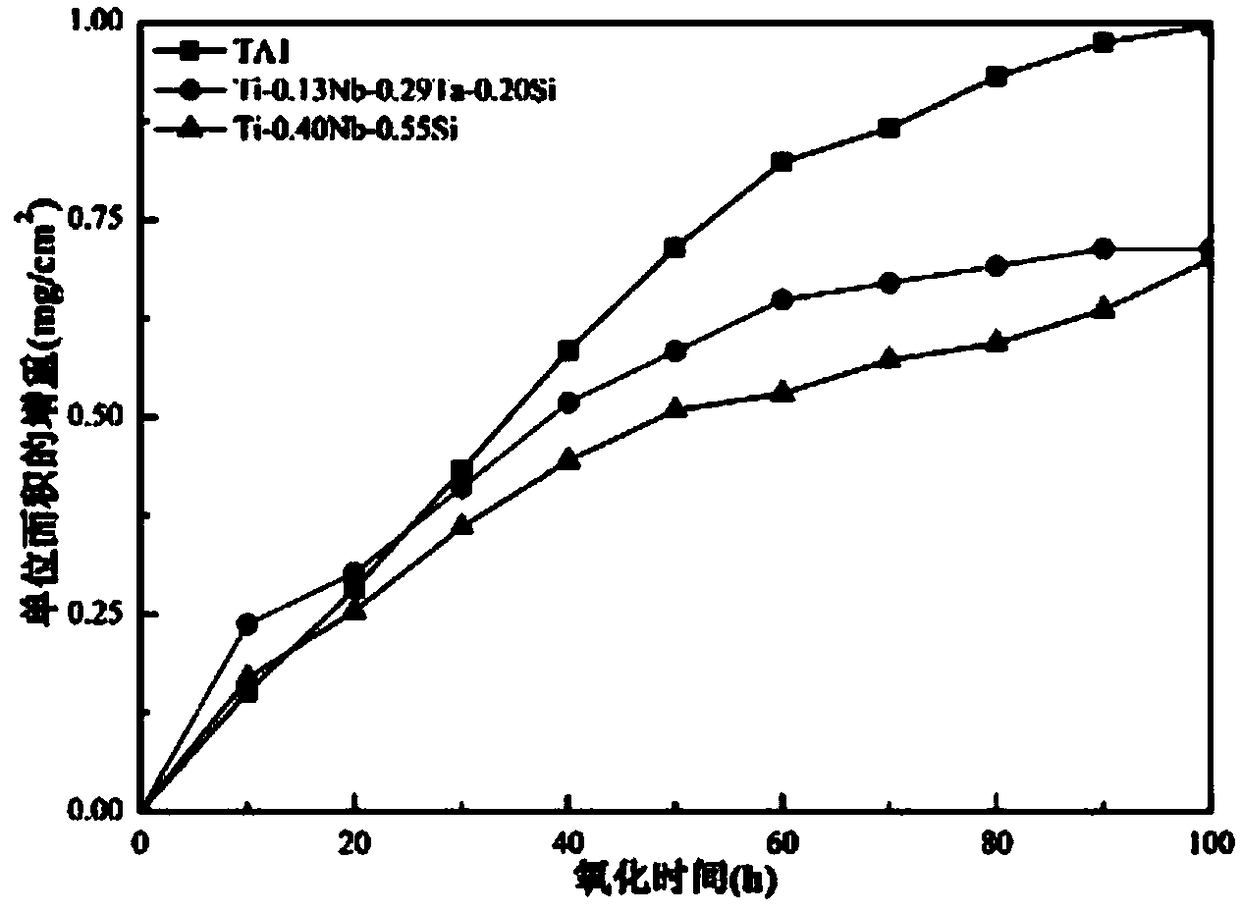

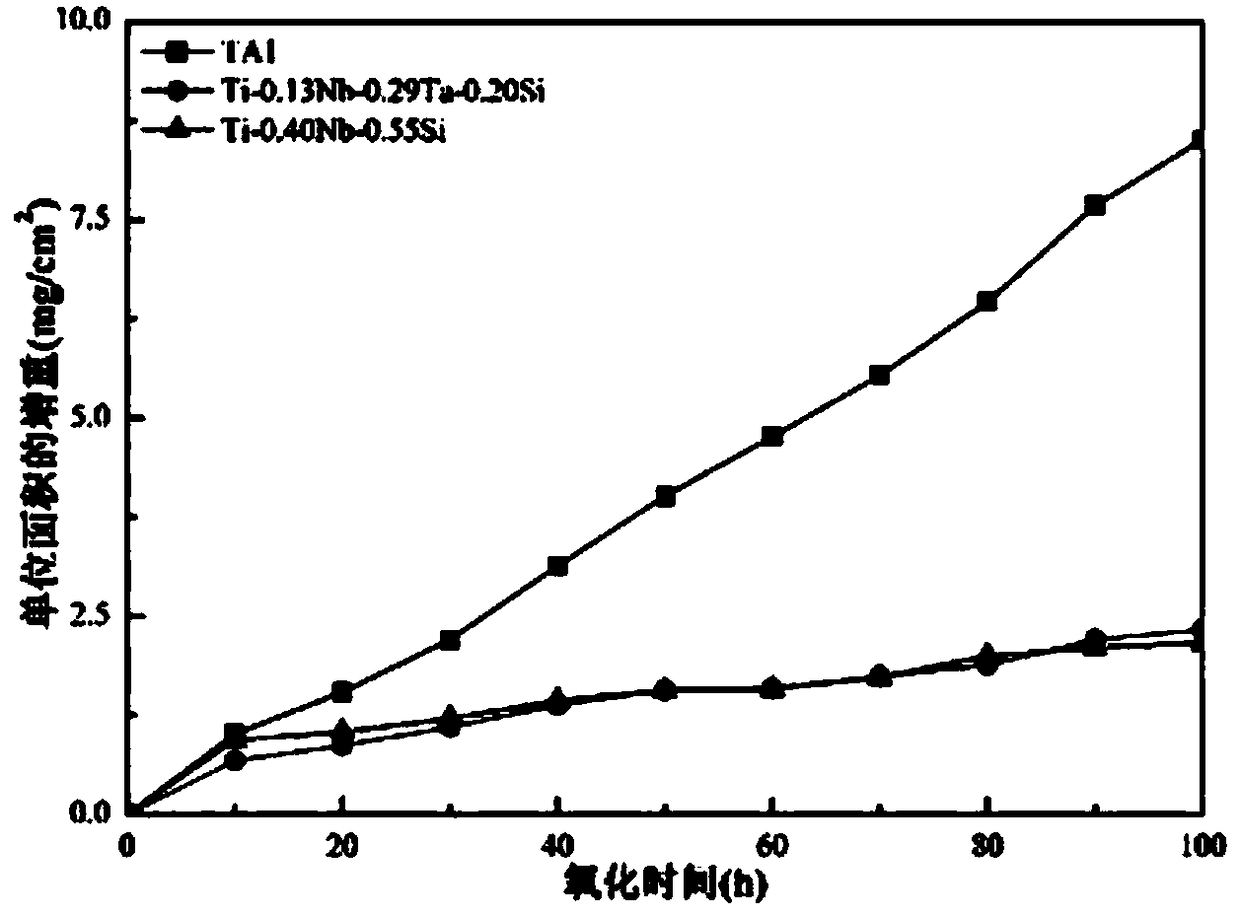

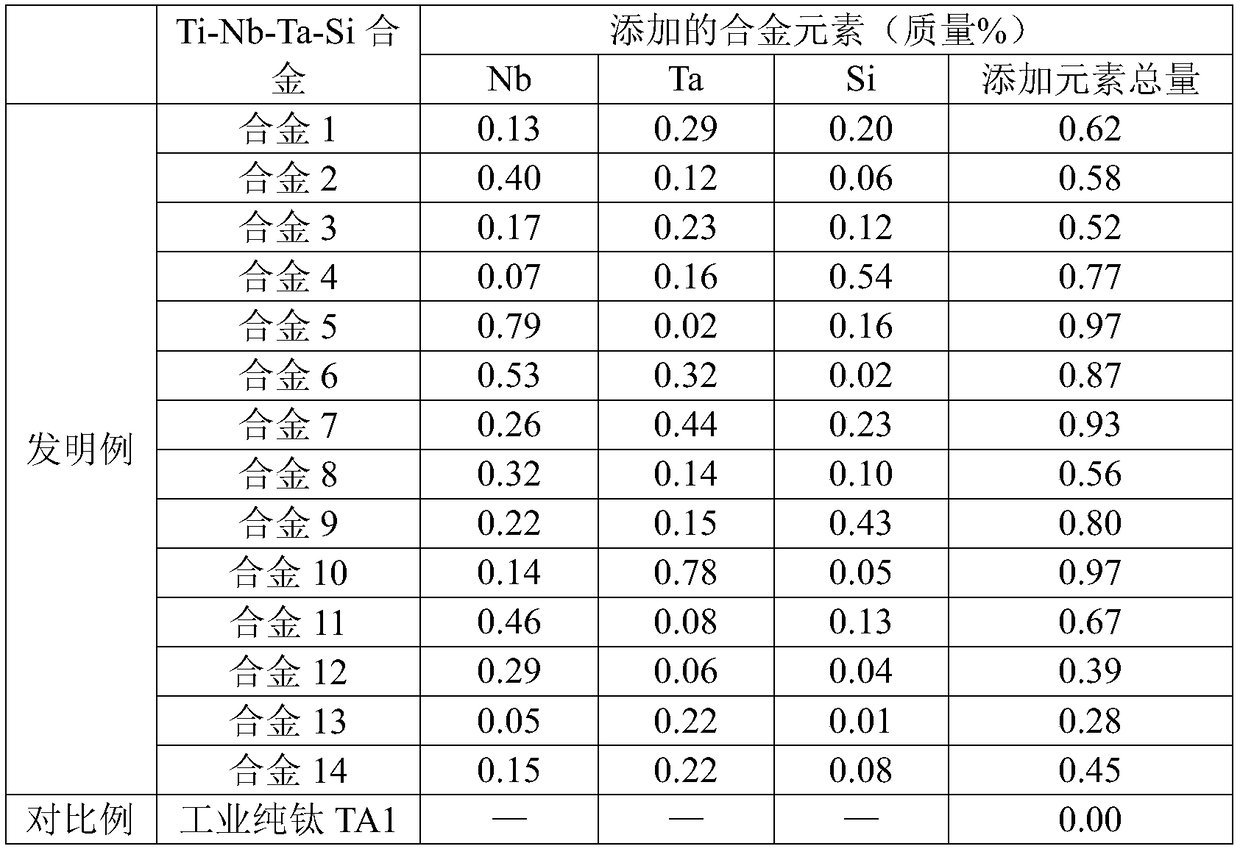

[0031] Chemical composition, preparation, oxidation behavior and mechanical properties of anti-oxidation Ti-Nb-Ta-Si alloy.

[0032] The anti-oxidation Ti-Nb-Ta-Si alloy utilizes the synergistic enhanced anti-oxidation effect among niobium (Nb), tantalum (Ta) and silicon (Si) elements to significantly improve the high-temperature anti-oxidation ability of titanium. In the anti-oxidation Ti-Nb-Ta-Si alloy, the content of individual Nb and Ta elements does not exceed 0.8%, the content of Si element does not exceed 0.6%, and the total amount of the above three elements added does not exceed 1% and is not low at 0.2%.

[0033] The chemical compositions of the 14 inventive examples of the oxidation-resistant Ti-Nb-Ta-Si alloys are shown in Table 1-1. The casting of the titanium alloy uses Ti powder, Nb powder, Ta powder and Si powder raw materials with a purity greater than 99.9% for vacuum consumable electric arc furnace melting. In order to ensure the uniformity of the compositi...

Embodiment 2

[0041] Anti-oxidation Ti-Nb-Si alloy chemical composition, preparation and testing of oxidation behavior and mechanical properties.

[0042] The anti-oxidation Ti-Nb-Si alloy utilizes the synergistic enhanced anti-oxidation effect between niobium (Nb) and silicon (Si) elements to improve the high-temperature anti-oxidation ability of titanium. In the anti-oxidation Ti-Nb-Si alloy, the content of Nb element is not more than 0.8%, the content of Si element is not more than 0.6%, and the total amount of the above two elements added is not more than 1% and not less than 0.2%.

[0043] The chemical compositions of the 6 inventive examples of the oxidation-resistant Ti-Nb-Si alloy are shown in Table 2-1. Use the Ti powder, Nb powder and Si powder with a purity greater than 99.9% to make a forged rod according to the preparation method provided in Example 1. Oxidation weight gain samples and mechanical property samples were prepared according to the method provided in Example 1. Th...

Embodiment 3

[0050] Chemical composition, preparation, oxidation behavior and mechanical properties of anti-oxidation Ti-W-Nb-Ta alloy.

[0051] The anti-oxidation Ti-W-Nb-Ta alloy utilizes the synergistic enhanced anti-oxidation effect among elements of tungsten (W), niobium (Nb) and tantalum (Ta) to improve the high-temperature anti-oxidation ability of titanium. In the anti-oxidation Ti-W-Nb-Ta alloy, the content of individual W, Nb and Ta elements is not more than 0.8%, and the total amount of the above three alloying elements added is not more than 1% and not less than 0.2%.

[0052] The chemical compositions of the five inventive examples of the oxidation-resistant Ti-W-Nb-Ta alloy are shown in Table 3-1. Using Ti powder, W powder, Nb powder and Ta powder with a purity greater than 99.9% to make a forging rod according to the preparation method provided in Example 1. Oxidation weight gain samples and mechanical property samples were prepared according to the method provided in Examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com