Preparation method of high-hardness strong-toughness high-manganese wear-resisting balls

A technology of wear-resistant balls and strong toughness, applied in the field of wear-resistant balls, can solve the problems of increased production costs, achieve the effects of reducing internal stress, improving toughness, and reducing the number of tempering treatments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

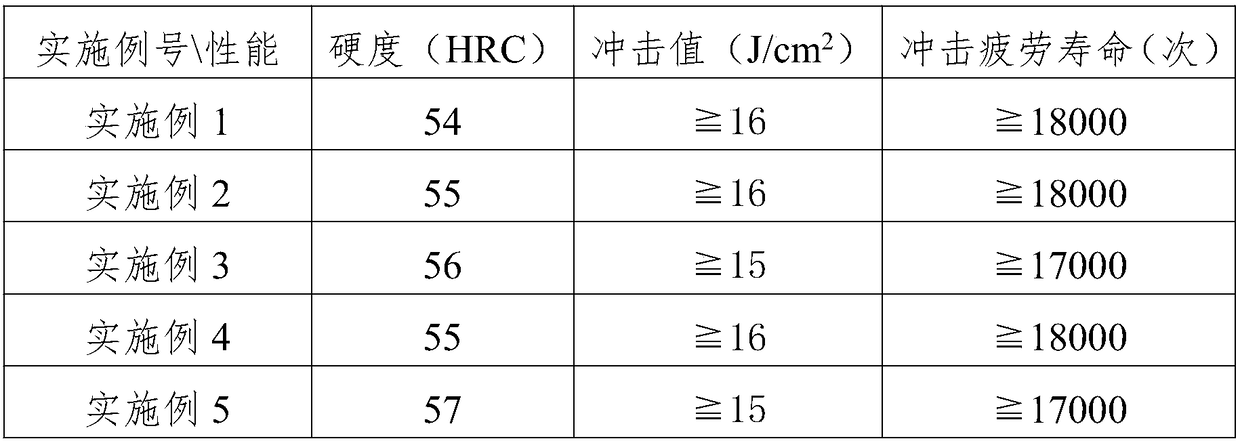

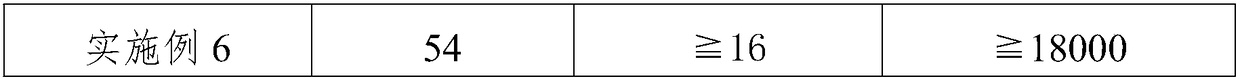

Examples

Embodiment 1

[0017] Add steel scrap, ferromanganese, recarburizer, metal aluminum, metal copper, ferromanganese nitride, ferrotungsten, ferrochrome, and ferrovanadium as raw materials into the electric furnace for melting. The melting temperature is 1580 ° C. Take a small amount of molten steel to study its composition Analysis, the mass fraction of elements in molten steel is controlled at: 13.5% Mn, 1.2% C, 2.2% Cr, 0.28% W, 0.40% V, 0.12% Al, 0.08% Cu, 0.65% N, 0.50% Si, 0.03% S, 0.05% P, the balance is Fe and unavoidable impurity elements;

[0018] After all the raw materials are melted, pour 1000kg of molten steel into the ladle, and add 5kg of composite modifier, 30% of Si-Ca alloy, 12% of Al-Sn alloy, 5% of Bi-Sb alloy, The rare element RE is 5.8%, and the rest is iron. When the molten steel is lowered to 1460°C, pour the molten steel in the ladle into the mold for casting. Average 0.8°C / S normalizing and cooling to 300°C to obtain crude wear-resistant balls;

[0019] Put the crud...

Embodiment 2

[0021] Add steel scrap, ferromanganese, recarburizer, metal aluminum, metal copper, ferromanganese nitride, ferrotungsten, ferrochrome, and ferrovanadium as raw materials into the electric furnace for melting. The melting temperature is 1580 ° C. Take a small amount of molten steel to study its composition Analysis, the mass fraction of elements in molten steel is controlled at: 16% Mn, 1.5% C, 2.8% Cr, 0.35% W, 0.52% V, 0.18% Al, 0.12% Cu, 0.70% N, 0.60% Si, 0.04% S, 0.06% P, the balance is Fe and unavoidable impurity elements;

[0022] After all the raw materials are melted, pour 1000kg of molten steel into the ladle, and add 5kg of composite modifier, 45% of Si-Ca alloy, 16% of Al-Sn alloy, 10% of Bi-Sb alloy, The rare element RE is 8.0%, and the rest is iron. When the molten steel is lowered to 1460°C, pour the molten steel in the ladle into the mold for casting. Average 0.8°C / S normalizing and cooling to 300°C to obtain crude wear-resistant balls;

[0023] Put the crude...

Embodiment 3

[0025] Add steel scrap, ferromanganese, recarburizer, metal aluminum, metal copper, ferromanganese nitride, ferrotungsten, ferrochrome, and ferrovanadium as raw materials into the electric furnace for melting. The melting temperature is 1600 ° C. Take a small amount of molten steel to study its composition Analysis, the mass fraction of elements in molten steel is controlled at: 13.5% Mn, 1.2% C, 2.2% Cr, 0.28% W, 0.40% V, 0.12% Al, 0.08% Cu, 0.65% N, 0.50% Si, 0.03% S, 0.05% P, the balance is Fe and unavoidable impurity elements;

[0026] After the raw materials are all melted, pour 1000kg of molten steel into the ladle, and add 30kg of composite modifier, 30% of Si-Ca alloy, 12% of Al-Sn alloy, 5% of Bi-Sb alloy, The rare element RE is 5.8%, and the rest is iron. When the molten steel is lowered to 1460°C, pour the molten steel in the ladle into the mold for casting. Average 0.8°C / S normalizing and cooling to 300°C to obtain crude wear-resistant balls;

[0027] Put the cru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com