Outer wall composite wall body with gypsum thermal-insulation mortar layers and application thereof

A technology of thermal insulation mortar layer and composite wall, which is applied to walls, building components, buildings, etc., can solve the problems of high cost of materials, transportation difficulties, and obstacles to threading on the construction site, so as to achieve a clean and tidy construction environment, good overall system performance, The light and dense effect of the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

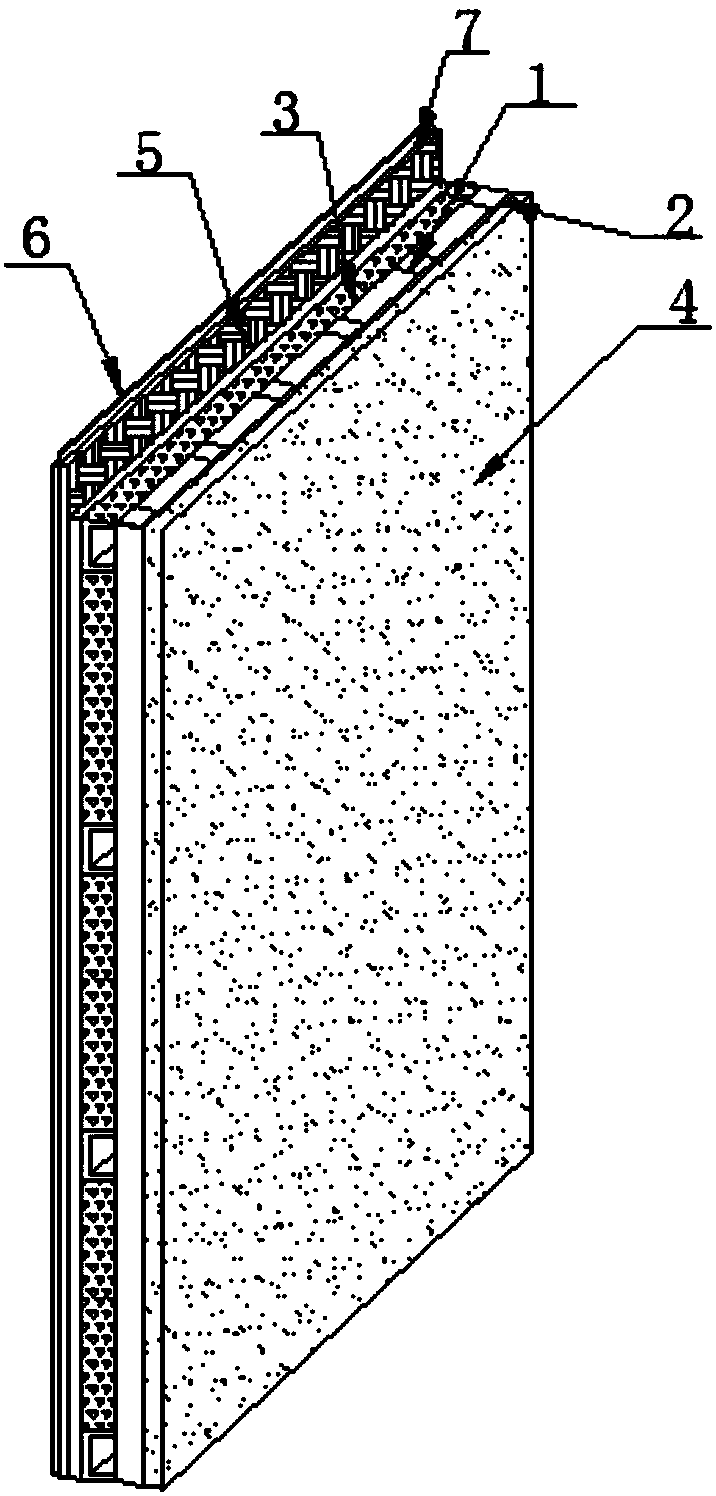

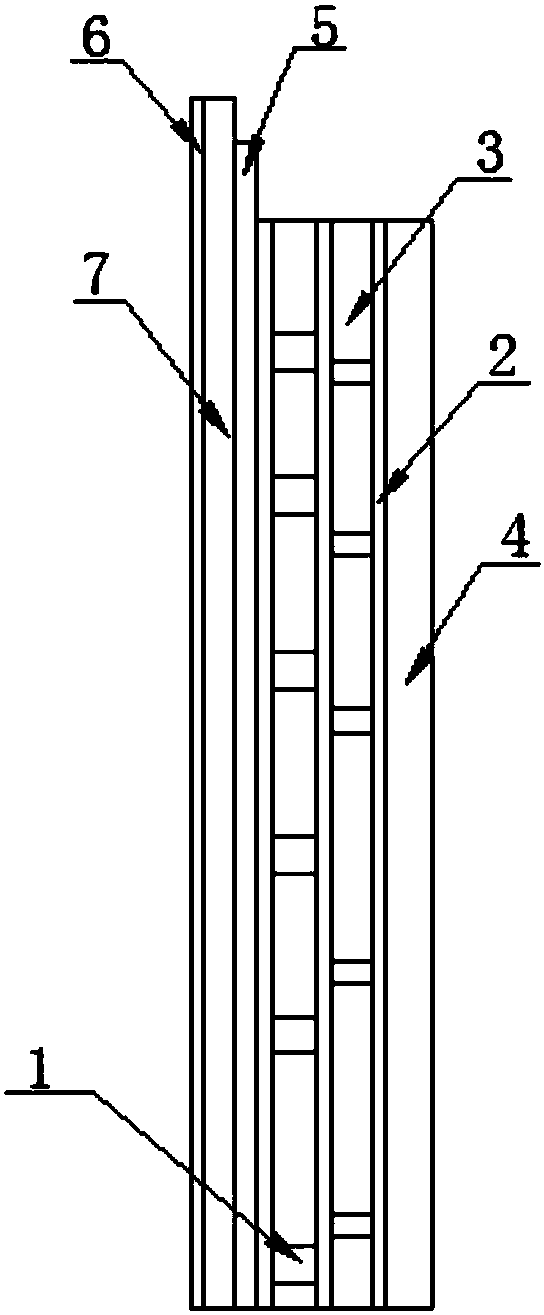

[0053]A composite wall with a gypsum thermal insulation mortar layer for an external wall, the thickness of which is 125mm, wherein the gypsum thermal insulation mortar layer is 60mm, the wall sprayed mortar layer is 30mm each, the thickness of the polymer waterproof and anti-cracking mortar layer is 5mm, and the heat transfer coefficient of the wall is 1.08 [W / m2.K]. A composite wall with a gypsum lightweight mortar layer for an external wall, including a profiled steel 1, a steel mesh 2, a gypsum insulation mortar layer 3, a first wall sprayed mortar layer 4, a second wall sprayed mortar layer 5, and polymer waterproofing Crack-resistant mortar layer 6, anti-corrosion mesh cloth 7.

[0054] Steel mesh 2 is installed on both sides of the profiled steel 1 and fixed to the beam-column structure, and is arranged inside the gypsum insulation mortar layer 3, the first wall sprayed mortar layer 4, and the second wall sprayed mortar layer 5, and The gypsum insulation mortar layer ...

Embodiment 2

[0070] A gypsum thermal insulation mortar layer exterior wall composite wall with a thickness of 145mm, wherein the gypsum thermal insulation mortar layer is 80mm, the wall sprayed mortar layer is 30mm each, the polymer waterproof and anti-cracking mortar layer is 5mm thick, and the heat transfer coefficient of the wall is 0.92[W / m2.K].

[0071] A composite wall with a gypsum lightweight mortar layer for an external wall, including a profiled steel 1, a steel mesh 2, a gypsum insulation mortar layer 3, a first wall sprayed mortar layer 4, a second wall sprayed mortar layer 5, and polymer waterproofing Crack-resistant mortar layer 6, anti-corrosion mesh cloth 7. A steel mesh 2 is installed in the middle of the section steel 1 and fixed to the beam-column structure, and is arranged inside the gypsum insulation mortar layer 3, the first wall spray mortar layer 4, and the second wall spray mortar layer 5, and the Integral structure; the gypsum thermal insulation mortar layer 3 i...

Embodiment 3

[0088] A composite wall with a gypsum thermal insulation mortar layer for the external wall, the thickness is 103 mm, in which the gypsum thermal insulation mortar layer is 60 mm, the wall sprayed mortar layer is 20 mm each, the polymer waterproof and anti-cracking mortar layer is 3 mm thick, and the heat transfer coefficient of the wall is 1.20 [W / m2.K].

[0089] A composite wall with a gypsum lightweight mortar layer for an external wall, including a profiled steel 1, a steel mesh 2, a gypsum insulation mortar layer 3, a first wall sprayed mortar layer 4, a second wall sprayed mortar layer 5, and polymer waterproofing Crack-resistant mortar layer 6, anti-corrosion mesh cloth 7. Steel mesh 2 is installed on the outside of the section steel 1 and fixed with the beam-column structure, and is arranged inside the gypsum insulation mortar layer 3, the first wall spray mortar layer 4, and the second wall spray mortar layer 5, and the Integral structure; the gypsum thermal insulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com