Boiler smoke and wind mixed heating adjusting system and control method thereof

A technology for adjusting the system and flue gas, which is applied in the direction of combustion method, combustion air/fuel supply, non-flammable liquid/gas transportation, etc. It can solve problems such as visual pollution, troublesome temperature adjustment and control, and excessive discharge of desulfurization wastewater. Achieve the effects of eliminating visual pollution, improving drying output, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

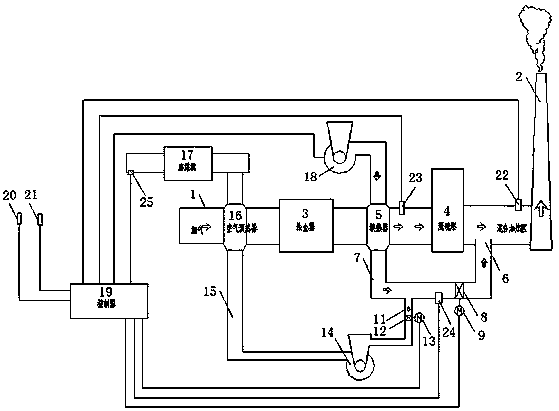

[0027] The boiler flue air mixing temperature rise adjustment system in this embodiment is as attached figure 1 As shown, the smoke outlet of the combustion chamber (not shown in the figure) is connected to the flue 1, and the smoke inlet of the flue is provided with a dust collector 3 and a desulfurization tower 4 in sequence, and a chimney 2 is connected to the end of the flue; its coal grinding The air inlet of the machine 17 is connected to the primary fan (blower) 14 through the pipe III15, and the air preheater 16 located on the flue is arranged on the pipe III, and the outlet of the coal mill is connected to the combustion chamber; The heat exchanger 5 in the channel, the air inlet of the heat exchanger is equipped with a fan 18, the air outlet of the heat exchanger communicates with the hot air inlet 6 on the flue at the outlet side of the desulfurization tower through the pipe I7, and the pipe I is provided with Damper I8; the air outlet of the heat exchanger is al...

Embodiment 2

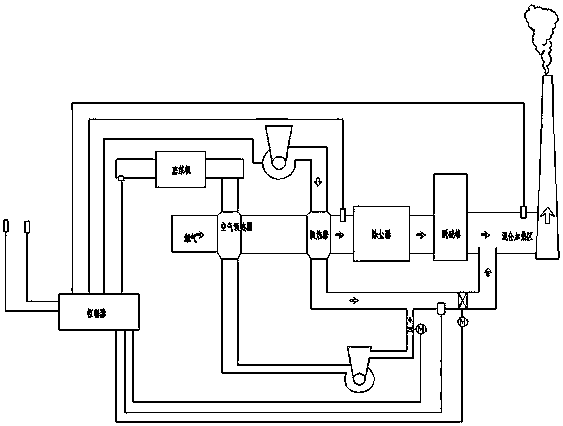

[0042] The difference between this embodiment and Embodiment 1 is that the heat exchanger 5 is installed in the flue at the inlet side of the dust collector. as attached figure 2 As shown in , this embodiment can reduce the temperature of the flue gas entering the dust collector by installing the heat exchanger in the flue at the inlet side of the dust collector, so as to avoid damage to the dust bag of the dust collector due to excessive flue gas temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com