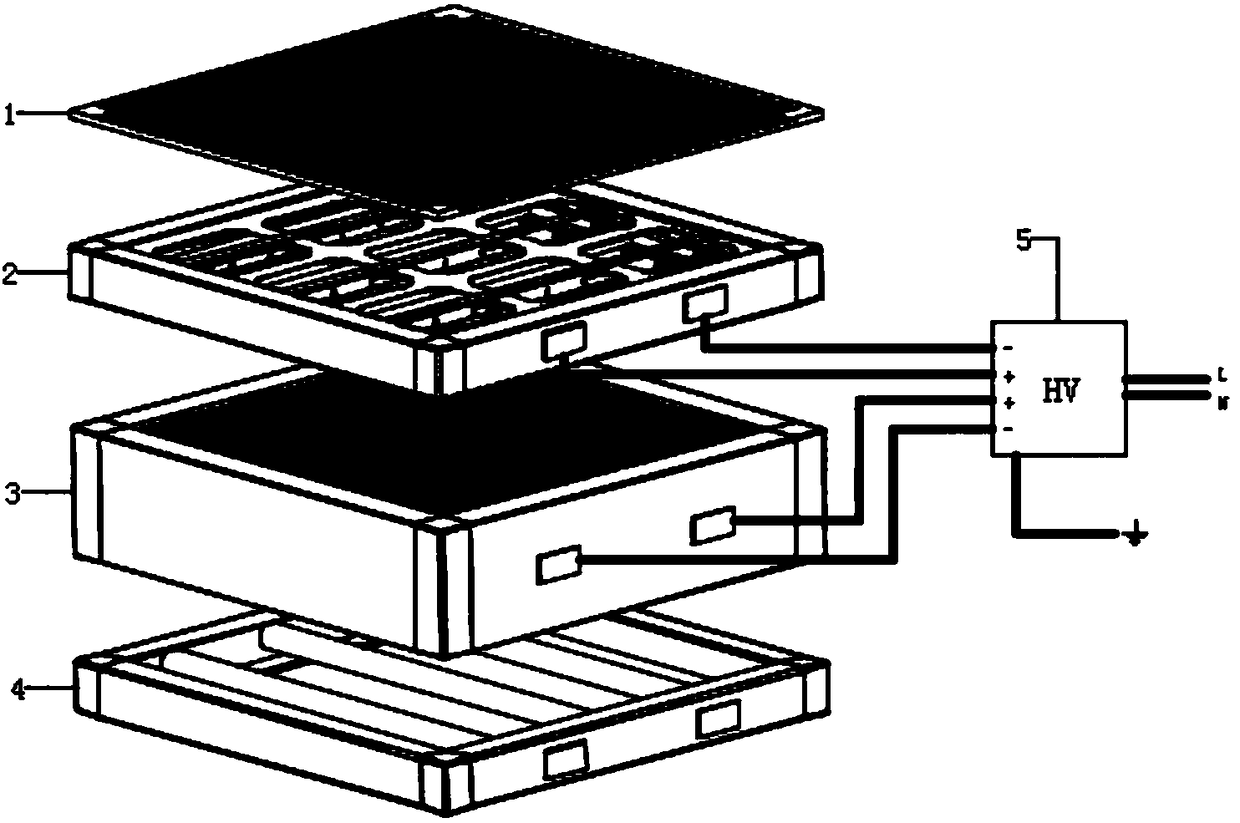

Multifunctional all-structural high-performance cleanable super-static air purification system

An air purification system and multi-functional technology, applied in air conditioning systems, external electrostatic separators, space heating and ventilation, etc., can solve problems such as increased wind resistance, increased costs, and failure to achieve waterproof sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0104] The initial effect net is made of mesh cloth and frame made by nanometer and nano modification technology. The initial effect net can be low-resistance filter materials such as mesh cloth, metal mesh, sponge, and spray-bonded cotton. The size of the initial filter screen is: 200*200*3mm.

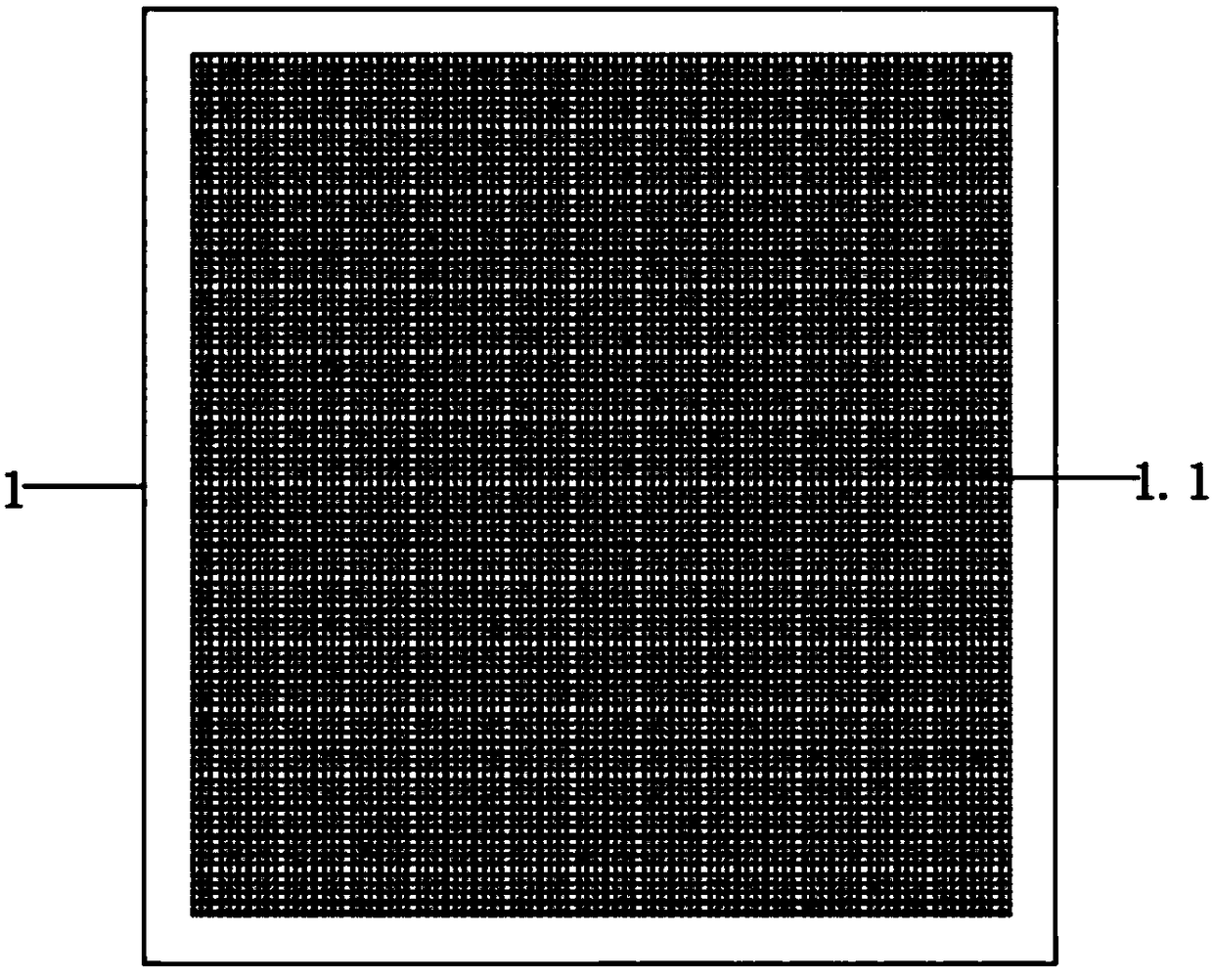

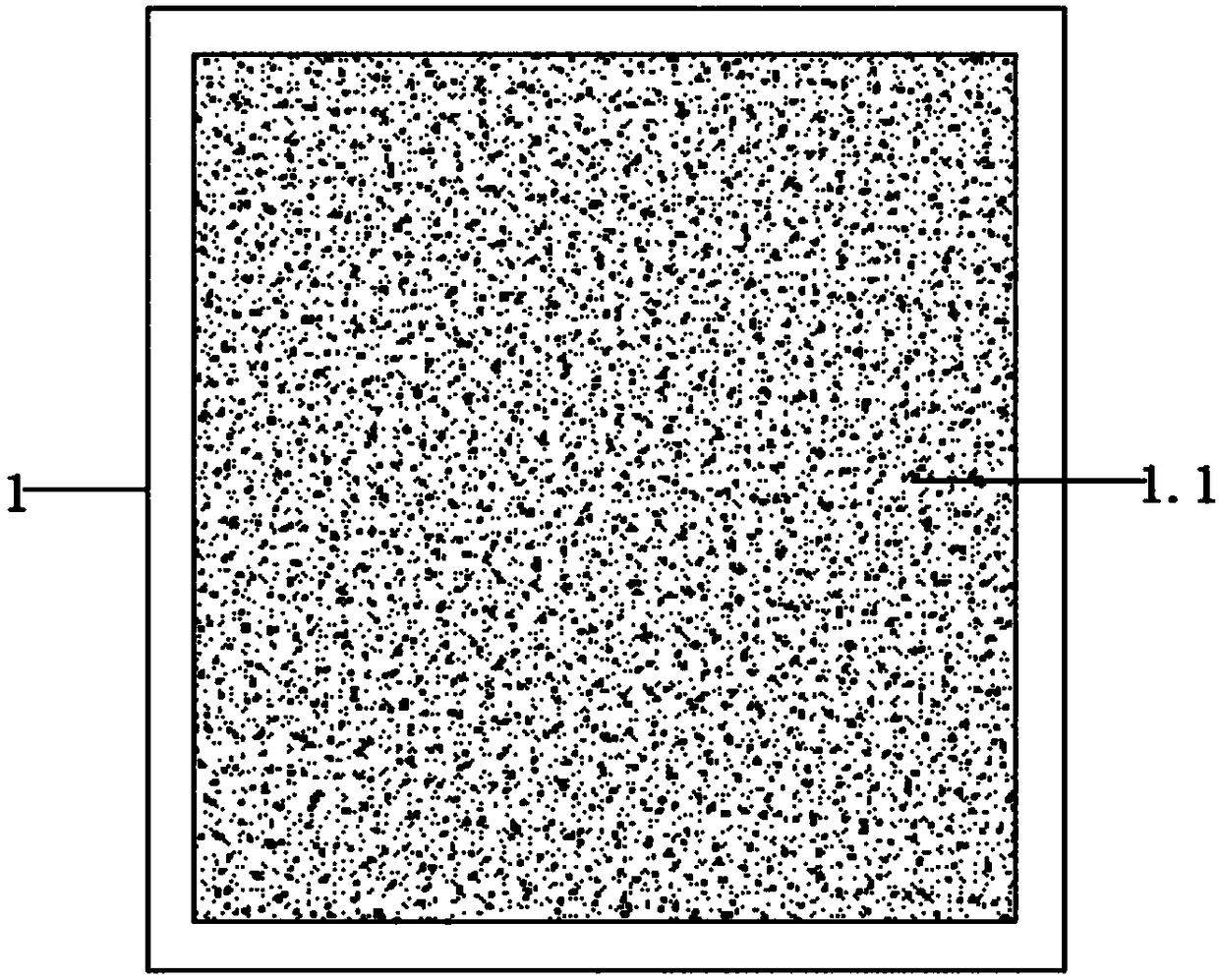

[0105] The ionization plate is made of stainless steel needles aligned with the center of the stainless steel plate, and the holes of the stainless steel plate are square holes with rounded corners (see Figure 3a), different from the conventional round hole, the rounded square hole increases the discharge distance, reduces the discharge and ozone generation, the stainless steel needle is flat or low to the stainless steel plate surface, the stainless steel needle uses PCB circuit board strips and high-voltage resistant silicone wire The connection is fixed in the fixed strip, the fixed strip is a U-shaped plastic strip, the plastic strip is sealed with silicone or epoxy polyurethane ...

Embodiment 2

[0110] On the basis of Example 1, the stainless steel needle of the ionization plate is changed into a carbon fiber brush, and the experimental results are shown in Figure 10-11 .

Embodiment 3

[0112] On the basis of Example 2, the stainless steel plate of the ionization plate is removed, and the ionization plate changes from a double electrode to a single electrode by removing the stainless steel plate, which can avoid discharge and ozone generation. The experimental results are shown in Figure 10-11.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com