Surface polish-grinding device and application thereof

A technology of grinding discs and components, applied in the direction of grinding drive devices, grinding machines, grinding racks, etc., can solve the problems of low efficiency, lack of equipment, high production costs, etc., and achieve the effects of reducing costs, wide application range, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

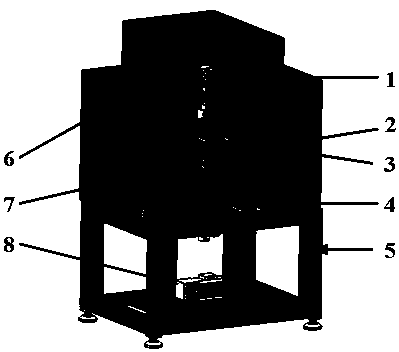

[0047] As shown in the figure, the device includes a column assembly, an upper grinding plate assembly, a lower grinding plate assembly, a detection module assembly, a bracket assembly, a vacuum adsorption assembly, a protective cover assembly, a control system, a column assembly, a lower grinding plate assembly, a detection module assembly, and a protective cover The components and the control system are respectively arranged on the bracket component. The protective cover assembly is located around the column assembly to prevent the workpiece from being polished and thrown away.

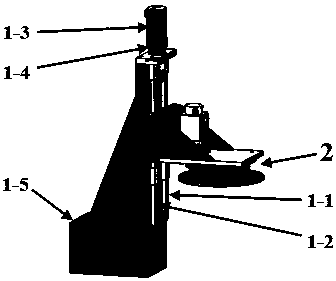

[0048] As shown in the figure, the column assembly includes a base, a ground screw, a guide rail, a column servo motor, and a column reducer. The column servo motor and the column reducer form a column drive mechanism. On the base, the column driving mechanism is connected with the ground screw. In the present invention, the base is made of cast iron, and the plane parallelism of the cast iron base...

Embodiment 2

[0051] Embodiment 2 Plane automatic polishing

[0052] Using the device of Example 1, the specific operation steps are as follows.

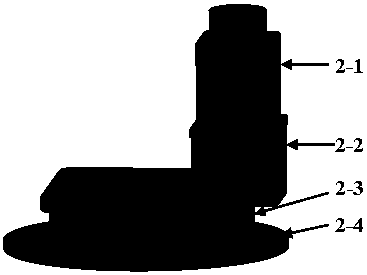

[0053] Step S1 Select a suitable vacuum rotary joint according to the size of the workpiece (outer circumference diameter 200-350 mm), replace the lower support with a vacuum rotary joint, and connect it to the vacuum adsorption component, and the servo motor of the lower plate is turned off.

[0054] In this embodiment, the vacuum rotary joint is composed of an aluminum alloy or stainless steel base and a rubber sealing strip, and a circular storage table is designed inside the vacuum rotary joint, which can hold workpieces with different shapes and characteristics. According to the size of the workpiece, the inner diameter of the vacuum rotary joint is designed in five sizes: 220mm, 250mm, 280mm, 320mm and 360mm, which can hold workpieces with an outer diameter within the range of 200-350 mm.

[0055] Step S2 Place the polished workpiece in th...

Embodiment 3

[0061] Embodiment 3 Plane semi-automatic polishing

[0062] Using the device of Example 1, the specific operation steps are as follows.

[0063] Step N1 Select a suitable lower grinding disc base according to the size of the workpiece (outer circumference diameter 200~350 mm), and paste different types of sandpaper according to the current roughness of the plane.

[0064] In this embodiment, five sizes of 220mm, 250mm, 280mm, 320mm and 360mm are designed for the base of the lower grinding disc, which can realize plane polishing of workpieces with an outer peripheral diameter in the range of 200-350 mm.

[0065] Step N2 Place the polished workpiece in the base of the lower grinding disc, use the detection module assembly to detect the parallelism of the plane of the workpiece to be polished, and adjust the parallelism.

[0066] Step N3 Set parameters such as the rotational speed of the lower disc base and polishing time on the panel of the control system, keep the upper disc b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com