High-strength self-cleaning permeable surface layer mortar and preparation method thereof

A self-cleaning, mortar technology, applied in the field of building materials, can solve the problems of unsatisfactory durability and poor mechanical properties, and achieve the effects of improved mechanical properties, high compressive strength, and good water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

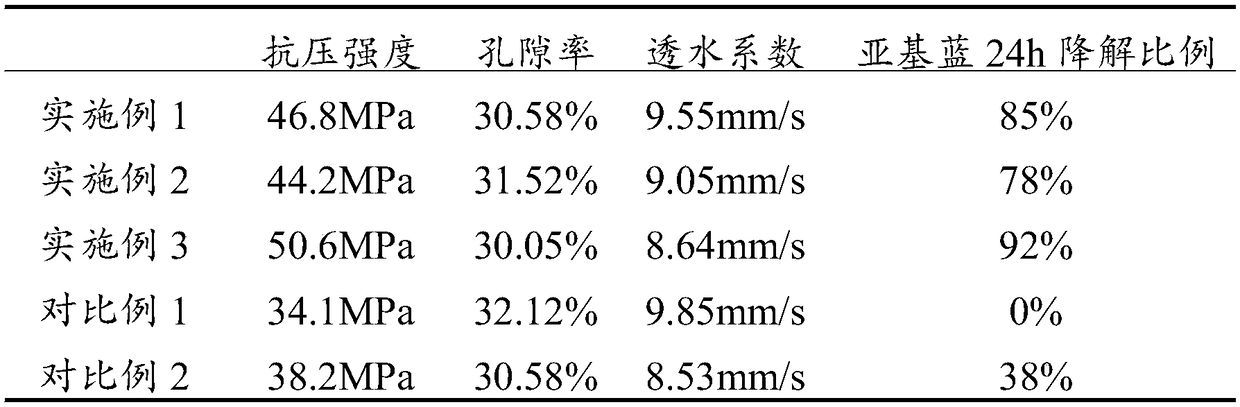

Examples

Embodiment 1

[0030] A high-strength self-cleaning permeable surface layer mortar includes the following raw materials in parts by weight: 100 parts of cement, 360 parts of machine-made sand, 1.0 part of water reducing agent, 1.0 part of aminated nano-silica, 1.0 part of nano-titanium dioxide, and 25 parts of water; Among them, the cement is P.O52.5 cement, and its specific surface area is greater than 280m 2 / kg; the particle size of the machine-made sand is 2.36-4.75mm, and the content of stone powder in the machine-made sand is not more than 0.5%; the water-reducing agent is a naphthalene-based water-reducer; The particle size of nano titanium dioxide is 25nm.

[0031] Among them, the aminated nano-silica is prepared by the following method: put 10g of nano-silica into 200ml of absolute ethanol, disperse it by ultrasonic waves for 6min while stirring, add 1ml of ammonia water drop by drop under the condition of sealing, and then drop by drop Add 3ml of silane coupling agent—γ-aminopropy...

Embodiment 2

[0039] A high-strength self-cleaning permeable surface mortar includes the following raw materials in parts by weight: 80 parts of cement, 350 parts of machine-made sand, 0.5 parts of water reducer, 0.5 parts of aminated nano-silica, 0.5 parts of nano-titanium dioxide, and 30 parts of water; Among them, the cement is P.O52.5 cement, and its specific surface area is greater than 280m 2 / kg; the particle size of the machine-made sand is 2.36-4.75mm, and the content of stone powder in the machine-made sand is not more than 0.5%; the water reducing agent is polycarboxylate water reducing agent; the particle size of the aminated nano-silica is 50-100nm , The particle size of nano-titanium dioxide is 25nm.

[0040] Among them, the aminated nano-silica is prepared by the following method: put 10g of nano-silica into 200ml of absolute ethanol, disperse it by ultrasonic waves for 5min while stirring, add 1ml of ammonia water drop by drop under the condition of sealing, and then drop by...

Embodiment 3

[0048] A high-strength self-cleaning permeable surface mortar includes the following raw materials in parts by weight: 120 parts of cement, 400 parts of machine-made sand, 1.5 parts of water reducing agent, 2 parts of aminated nano-silica, 2 parts of nano-titanium dioxide, and 30 parts of water; Among them, the cement is P.O52.5 cement, and its specific surface area is greater than 280m 2 / kg; the particle size of the machine-made sand is 2.36-4.75mm, and the content of stone powder in the machine-made sand is not more than 0.5%; the water reducing agent is polycarboxylate water reducing agent; the particle size of the aminated nano-silica is 50-100nm , The particle size of nano-titanium dioxide is 25nm.

[0049] Among them, the aminated nano-silica is prepared by the following method: put 10g of nano-silica into 200ml of absolute ethanol, disperse it by ultrasonic waves for 10min while stirring, add 1ml of ammonia water drop by drop under the condition of sealing, and then dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com