Graphene wood-plastic micro-foaming material with uniform foam and preparation method of micro-foaming material

A graphene and micro-foaming technology, applied in the field of foaming materials, can solve the problems of poor mechanical properties of materials, poor interface bonding between wood powder and resin, and poor foaming quality, and achieves good interface bonding, good hardness, and foaming. Good quality foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

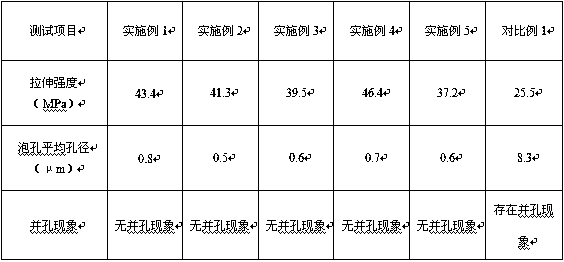

Examples

Embodiment 1

[0031] a. Pulverize wood and bamboo to obtain wood powder, wash it with lye, filter and dry it with silicon micropowder and graphene under the protection of an inert gas, disperse it through ultrasonic-vacuum cooperation, wash it with water, dry it, and treat it on the surface of the wood powder with alkali Under the action of alkali, silicon micropowder, wood powder and graphene are linked into fine powder to obtain composite powder; wherein: 50 parts by weight of wood powder, 5 parts by weight of microsilica powder, and 1 part by weight of graphene;

[0032] b. Mix the composite powder with the resin and the zeolite molecular sieve, stir at high speed for 20 minutes, make the mixture evenly, and prepare the mixture; wherein: 25 parts by weight of the composite powder, 72 parts by weight of the resin, and 2 parts by weight of the zeolite molecular sieve;

[0033] c, using a twin-screw extruder to extrude and granulate the mixture to obtain mixed pellets;

[0034] d. Add a foa...

Embodiment 2

[0038] a. Pulverize wood and bamboo to obtain wood powder, wash it with lye, filter and dry it with silicon micropowder and graphene under the protection of an inert gas, disperse it through ultrasonic-vacuum cooperation, wash it with water, dry it, and treat it on the surface of the wood powder with alkali Under the action of alkali, silicon micropowder, wood powder and graphene are linked into fine powder to obtain composite powder; wherein: 60 parts by weight of wood powder, 10 parts by weight of microsilica powder, and 1 part by weight of graphene;

[0039] b. Mix the composite powder with the resin and the zeolite molecular sieve, stir at high speed for 20 minutes, make the mixture evenly, and prepare the mixture; wherein: 25 parts by weight of the composite powder, 72 parts by weight of the resin, and 3 parts by weight of the zeolite molecular sieve;

[0040] c, using a twin-screw extruder to extrude and granulate the mixture to obtain mixed pellets;

[0041]d. Add a foa...

Embodiment 3

[0045] a. Pulverize wood and bamboo to obtain wood powder, wash it with lye, filter and dry it with silicon micropowder and graphene under the protection of an inert gas, disperse it through ultrasonic-vacuum cooperation, wash it with water, dry it, and treat it on the surface of the wood powder with alkali Under the action of alkali, silicon micropowder, wood powder and graphene are linked into fine powder to obtain composite powder; wherein: 80 parts by weight of wood powder, 12 parts by weight of microsilica powder, and 2 parts by weight of graphene;

[0046] b. Mix the composite powder with resin and zeolite molecular sieve, stir at high speed for 30min, make the mixture evenly, and prepare the mixture; wherein: 30 parts by weight of composite powder, 88 parts by weight of resin, and 4 parts by weight of zeolite molecular sieve;

[0047] c, using a twin-screw extruder to extrude and granulate the mixture to obtain mixed pellets;

[0048] d. Add a foaming agent to the mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com