Thermoelectric device with adaptive connection layer

A technology of thermoelectric devices and connecting layers, applied in the direction of thermoelectric devices that only utilize the Peltier or Seebeck effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

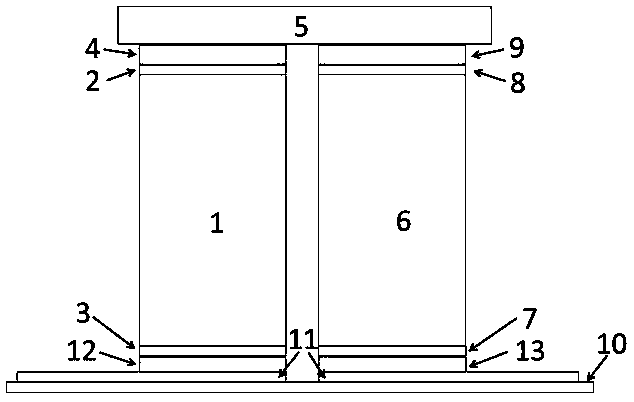

[0044] N-type and p-type skutterudite samples with a barrier layer and an electrode were sintered with a diameter of 50 mm and a thickness of 8 mm by a one-step sintering process, and their structures were Ni / Ti-Al / Yb, respectively 0.3 co 4 Sb 12 / Ti-Al / Ni and Ni / Ti-Al / CeFe 4 Sb 12 / Ti-Al / Ni, where Ni is the electrode with a thickness of about 120 μm, and Ti-Al is the barrier layer with a thickness of about 100 μm. The corresponding thermoelectric element is obtained by wire cutting, and the size is 4*4*8mm 3 . Then through the brazing process, with the help of Cu-Ag solder, the high temperature ends of the above n-type and p-type components are passed through with a size of 5*12*2mm 3 The Mo-Cu baffles are rigidly connected to obtain the corresponding thermoelectric pair;

[0045] The circuit design of the cold end of the thermoelectric device is carried out, and the appropriate copper-clad ceramic substrate is selected accordingly, so that a thermoelectric device compo...

Embodiment 2

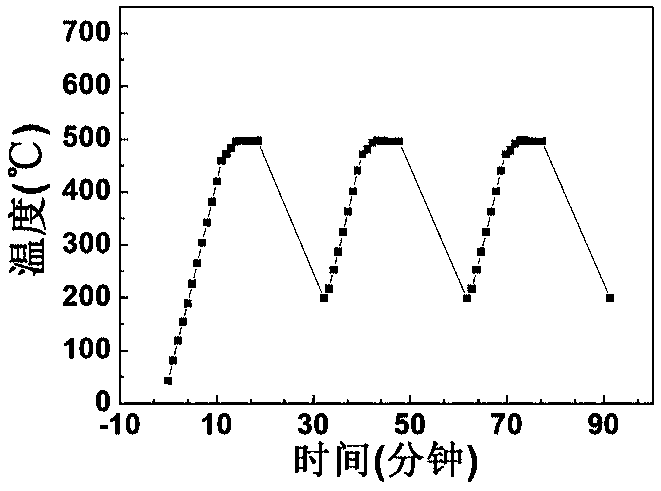

[0052] Referring to the steps of Example 1, a thermoelectric device C consisting of 8 thermoelectric pairs connected in series with each interface rigidly connected was prepared. As a comparison, 8 thermoelectric pairs were randomly selected, and the copper-clad ceramic substrate and the cold ends of the thermoelectric pairs were ultrasonically cleaned and dried. Place the surface of the copper-clad ceramic substrate on the heating platform, with the copper-clad side facing up. The size of 4*4*0.02mm is placed on the surface of the copper clad layer of the substrate corresponding to the cold end of the n-type and p-type components. 3 The In foil (thickness is 300 μm) and Sn foil (thickness is 300 μm), the cold end of the thermoelectric pair n-type thermoelectric element and the p-type thermoelectric element are placed on the In foil and the Sn foil respectively, and 0.01 is applied to the cold end of the thermoelectric pair. ~0.5MPa pressure and maintain. Turn on the heating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com