Turbine and preparation method for turbine wax molds

A technology of turbines and wax molds, which is applied in the direction of manufacturing tools, casting molding equipment, metal processing equipment, etc., can solve problems such as poor surface finish, long mold manufacturing cycle, and affecting rotor imbalance, and achieve excellent tensile strength and toughness. The effect of good surface finish and excellent safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

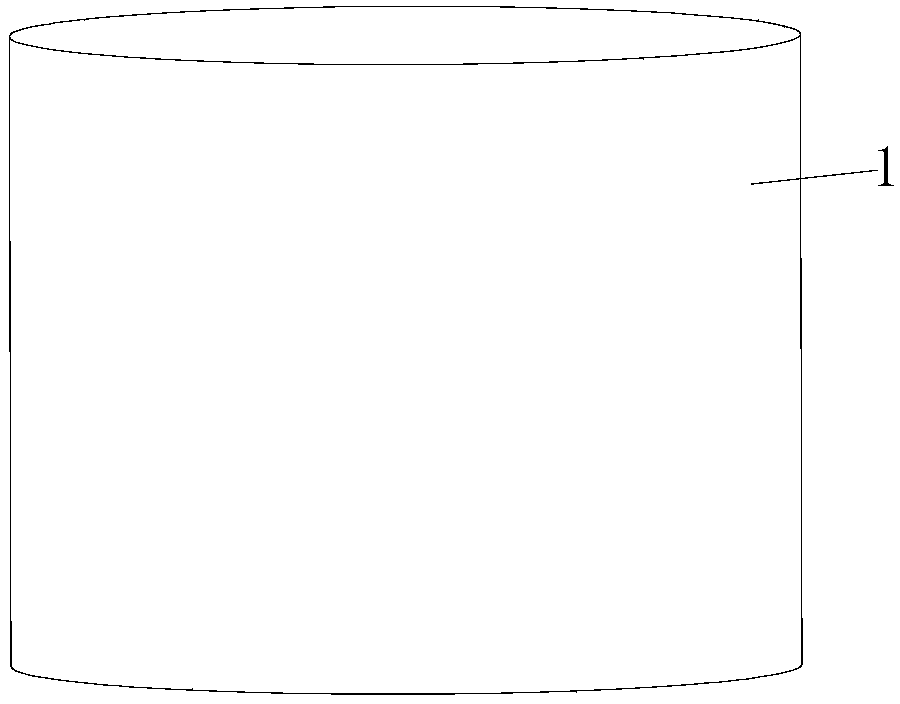

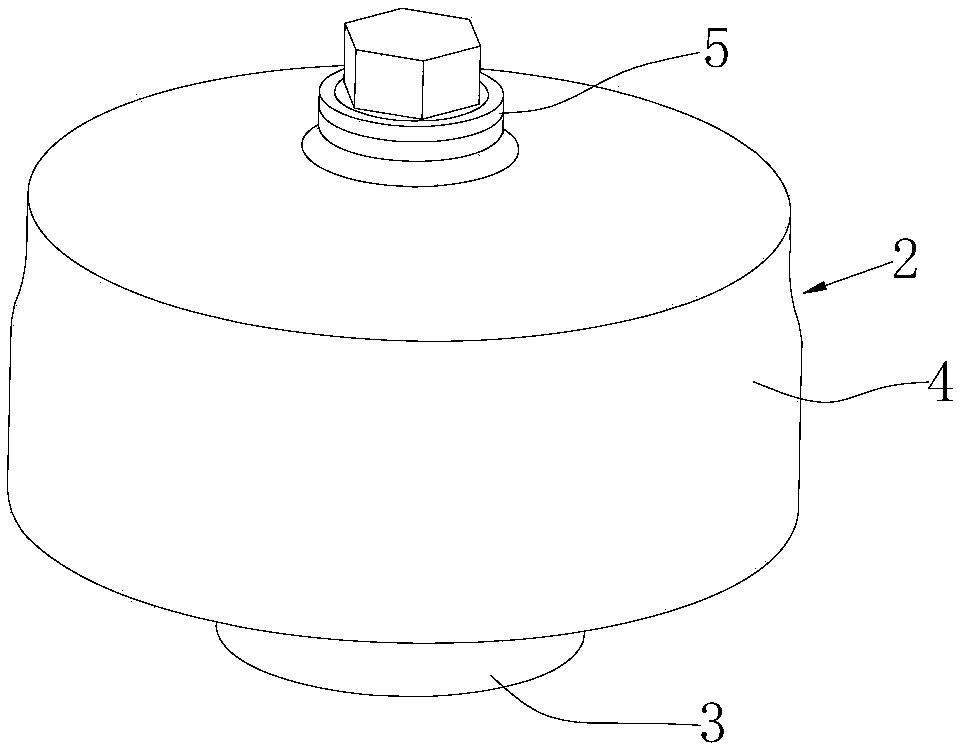

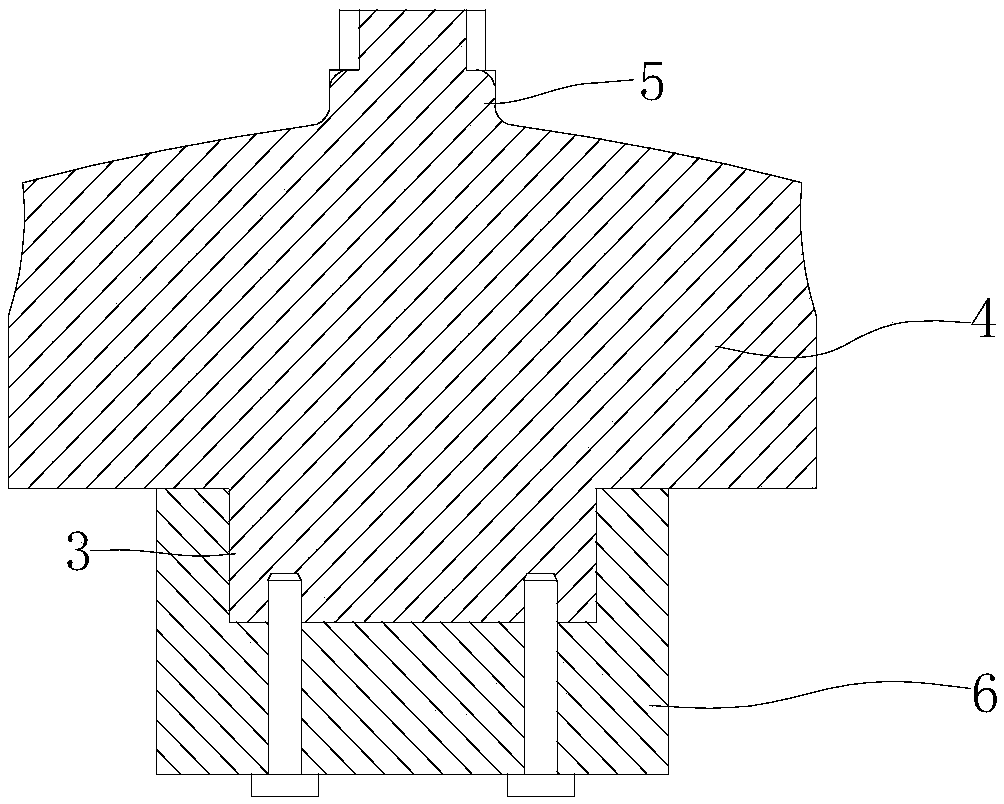

[0037] Such as Figure 1 to Figure 4 Shown, the preparation method of turbine wax pattern of the present invention may further comprise the steps:

[0038] Step 1. First make a cutting wax blank by the following process:

[0039] Heat the paraffin to melt, and control the temperature of the melted paraffin at 95°C;

[0040] Heat and melt the polyethylene, pour the melted polyethylene into the paraffin melt, and stir evenly to obtain a concentrate of paraffin and polyethylene;

[0041] Adding stearic acid and beeswax to the concentrate of paraffin wax and polyethylene and stirring uniformly to form a mixed material, keeping the temperature of the mixed material at 120°C, adding carbon fiber powder to the mixed material and stirring evenly to obtain a paraffin-based composite rod;

[0042] The paraffin-based composite bar is injected into the mold, and after cooling and solidifying, a machinable wax blank 1 (such as figure 1 shown). The solid machinable wax blank 1 obtained ...

Embodiment 2

[0057] Heating the paraffin to melt, and controlling the temperature of the molten paraffin at 100°C;

[0058] Heat and melt the polyethylene, pour the melted polyethylene into the paraffin melt, and stir evenly to obtain a concentrate of paraffin and polyethylene;

[0059] Adding stearic acid and beeswax to the concentrate of paraffin wax and polyethylene and stirring uniformly to form a mixed material, keeping the temperature of the mixed material at 125°C, adding carbon fiber powder to the mixed material and stirring evenly to obtain a paraffin-based composite rod;

[0060] The paraffin-based composite bar is injected into the mold, and after cooling and solidification, a cutting wax blank is formed.

[0061] In the machinable wax blank of the present embodiment, the proportion of stearic acid is 9%, the proportion of polyethylene is 2%, the proportion of beeswax is 5%, the proportion of carbon fiber powder is 1.5%, and the balance For paraffin.

[0062] The rest of the p...

Embodiment 3

[0064] Heat the paraffin to melt, and control the temperature of the melted paraffin at 105°C;

[0065] Heat and melt the polyethylene, pour the melted polyethylene into the paraffin melt, and stir evenly to obtain a concentrate of paraffin and polyethylene;

[0066] Adding stearic acid and beeswax to the concentrate of paraffin wax and polyethylene and stirring uniformly to form a mixed material, keeping the temperature of the mixed material at 130°C, adding carbon fiber powder to the mixed material and stirring evenly to obtain a paraffin-based composite rod;

[0067] The paraffin-based composite bar is injected into the mold, and after cooling and solidification, a cutting wax blank is formed.

[0068] In the machinable wax blank of the present embodiment, the proportion of stearic acid is 10%, the proportion of polyethylene is 3%, the proportion of beeswax is 6%, the proportion of carbon fiber powder is 2%, and the balance For paraffin.

[0069] The rest of the process i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com