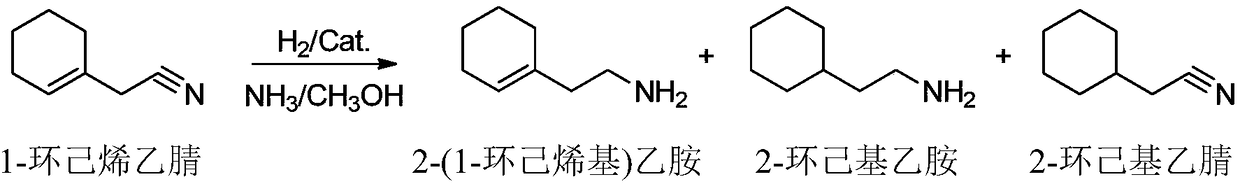

Method for producing 2-(1-cyclohexenyl)ethylamine

A cyclohexenyl, cyclohexene acetonitrile technology, applied in chemical instruments and methods, preparation of amino compounds, preparation of organic compounds, etc., can solve the problems such as the decrease of the main reaction rate and the increase of the yield, which is only 72.3%, It can improve the utilization rate, facilitate industrial production, and reduce the side reaction of double bond reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment relates to a method for producing 2-(1-cyclohexenyl)ethylamine, specifically comprising the following steps:

[0028] In a 2000-liter high-pressure hydrogenation reactor equipped with a steam heating jacket, internal cooling coil, strong mechanical agitation and a hydrogen flow meter (which can display the flow rate and total flow of hydrogen), introduce the raw material 1-cyclohexene acetonitrile 500Kg, solvent isopropanol 1000Kg, Ni / Al / Fe three-component catalyst 33Kg, after replacing the gas in the kettle with nitrogen and hydrogen successively, press in 31Kg of liquid ammonia. Pressurize the hydrogen to 2.5MPa, start stirring, and raise the temperature above 80°C, and the reaction starts to consume a lot of hydrogen. The amount of hydrogen introduced and the flow rate of cooling water are controlled to keep the reaction temperature at 100-105° C. and the reaction pressure at 2.5-3.0 MPa. At the same time, the hydrogen flow meter displays the hydroge...

Embodiment 2

[0032] This embodiment relates to a method for producing 2-(1-cyclohexenyl)ethylamine, specifically comprising the following steps:

[0033] In a 2000-liter high-pressure hydrogenation reactor equipped with a steam heating jacket, internal cooling coil, strong mechanical agitation and a hydrogen flow meter (which can display the flow rate and total flow of hydrogen), introduce the raw material 1-cyclohexene acetonitrile 500Kg, solvent methanol 1000Kg, Ni / Al / Fe three-component catalyst 40Kg, replace the gas in the kettle with nitrogen and hydrogen successively, and then press 31Kg of liquid ammonia. Pressurize the hydrogen to 2.5MPa, start stirring, and raise the temperature above 80°C, and the reaction starts to consume a lot of hydrogen. The amount of hydrogen introduced and the flow rate of cooling water are controlled to keep the reaction temperature at 100-105° C. and the reaction pressure at 2.5-3.0 MPa. At the same time, the hydrogen flow meter displays the hydrogen con...

Embodiment 3

[0037] This embodiment relates to a method for producing 2-(1-cyclohexenyl)ethylamine, specifically comprising the following steps:

[0038]In a 2000-liter high-pressure hydrogenation reactor equipped with a steam heating jacket, internal cooling coil, strong mechanical agitation and a hydrogen flow meter (which can display the flow rate and total flow of hydrogen), introduce the raw material 1-cyclohexene acetonitrile 500Kg, solvent isopropanol 1000Kg, Ni / Al / Fe three-component catalyst 33Kg, after replacing the gas in the kettle with nitrogen and hydrogen successively, press in 31Kg of liquid ammonia. Pressurize the hydrogen to 2.5MPa, start stirring, and raise the temperature above 80°C, and the reaction starts to consume a lot of hydrogen. The amount of hydrogen introduced and the flow rate of cooling water are controlled to keep the reaction temperature at 100-105° C. and the reaction pressure at 2.5-3.0 MPa. At the same time, the hydrogen flow meter displays the hydrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com