Environment-friendly water-based paint with adsorption and purification function and preparation method thereof

A water-based paint, environmentally friendly technology, applied in the direction of polyurea/polyurethane paint, coating, etc., can solve the problems of excessive plasticizer, endanger people's health, pollute the environment, etc., achieve low production cost, high strength, short growth cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

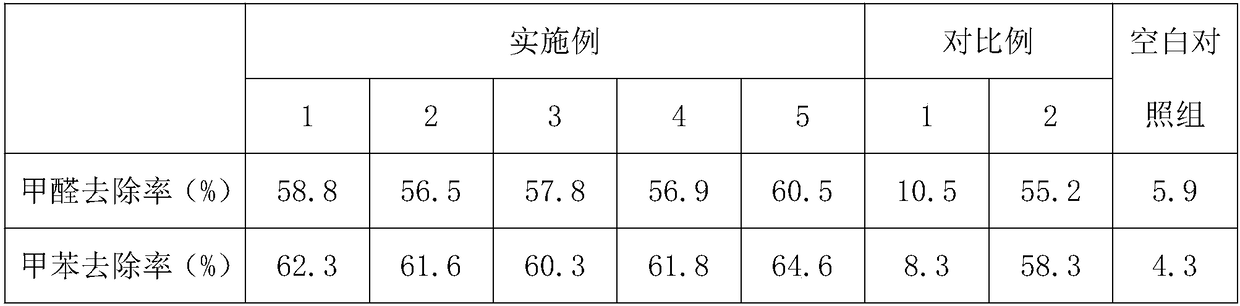

Examples

Embodiment 1

[0023] In this embodiment 1, a kind of environment-friendly water-based paint with adsorption and purification function, the water-based paint is made of the following raw materials in parts by weight: 500 parts of deionized water, 80 parts of modified bamboo activated carbon powder, 100 parts of polyurethane resin Parts, 50 parts of glycerin epoxy resin, 20 parts of defoamer.

[0024] The preparation method of above-mentioned waterborne paint, comprises the steps:

[0025] (1) Preparation of modified bamboo activated carbon powder: Mix bamboo chips with phosphoric acid solution and knead for 10 minutes, and directly contact the kneaded material with flue gas at 400°C for 3.5 hours in countercurrent, so that the material is carbonized and After activation, the activated material is obtained. After the activated material is washed, dried, crushed and ground, the modified bamboo activated carbon powder is obtained. The impregnation ratio of the bamboo chips to the phosphoric aci...

Embodiment 2

[0029] In this embodiment 2, a kind of environment-friendly water-based paint with adsorption and purification function, the water-based paint is made of the following raw materials in parts by weight: 600 parts of deionized water, 120 parts of modified bamboo activated carbon powder, 200 parts of polyurethane resin Parts, 80 parts of glycerin epoxy resin, 30 parts of defoamer.

[0030] The preparation method of above-mentioned waterborne paint, comprises the steps:

[0031] (1) Preparation of modified bamboo activated carbon powder: Mix bamboo chips with phosphoric acid solution and knead for 30 minutes, and directly contact the kneaded material with flue gas at 650° C. for 4.5 hours, so that the material is carbonized and After activation, the activated material is obtained. After the activated material is washed, dried and pulverized, the modified bamboo activated carbon powder is obtained. The impregnation ratio of the bamboo chips to the phosphoric acid solution is 1:1.6;...

Embodiment 3

[0035] In this embodiment 3, a kind of environment-friendly water-based paint with adsorption and purification function is made of the following raw materials in parts by weight: 520 parts of deionized water, 90 parts of modified bamboo activated carbon powder, 120 parts of polyurethane resin Parts, 60 parts of glycerin epoxy resin, 22 parts of defoamer.

[0036] The preparation method of above-mentioned waterborne paint, comprises the steps:

[0037] (1) Preparation of modified bamboo activated carbon powder: Mix bamboo chips with phosphoric acid solution and knead for 20 minutes, and directly contact the kneaded material with flue gas at 525°C for 4 hours in countercurrent to carbonize and activate the material Finally, the activated material is obtained. After the activated material is washed, dried and pulverized, the modified bamboo activated carbon powder is obtained. The impregnation ratio of the bamboo chips and the phosphoric acid solution is 1:1.5; The particle size...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com