Dust falling agent and preparing method thereof

A dust-reducing agent and additive technology, which is applied in the field of dust-reducing agent and its preparation, can solve the problems of sticky mixture of dust and dust-reducing agent, large size of sprinkler equipment, and large space occupied by open space, so as to achieve improved dust-reducing effect and small environmental hazards , the effect of reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

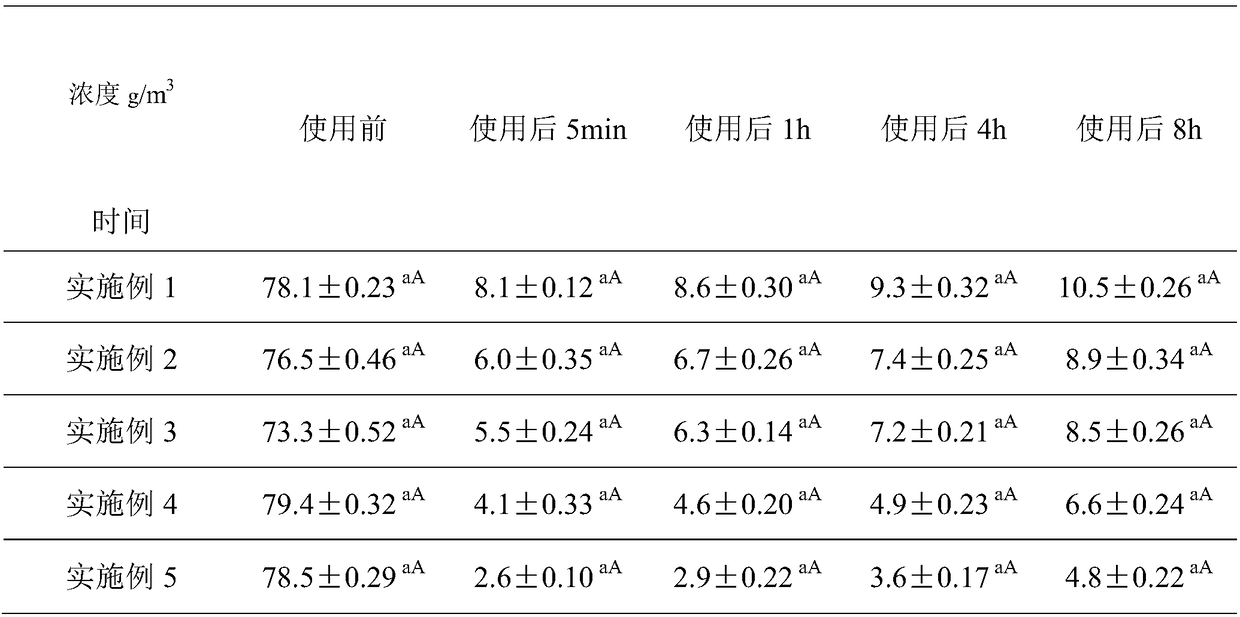

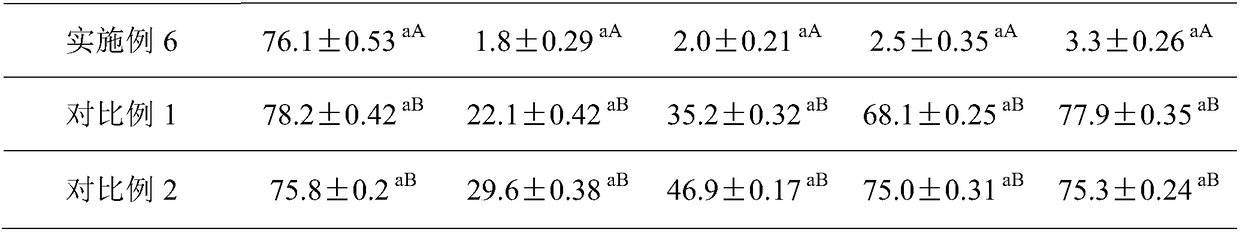

Examples

Embodiment 1

[0020] A dust suppressant:

[0021] (1) Raw materials: 1 part of carboxymethyl cellulose, 3 parts of polyacrylamide, 1 part of hydroxypropyl methylcellulose, 1 part of lithium bentonite, 8 parts of glycerin and 986 parts of water;

[0022] The preparation method of lithium-based bentonite: Soak 10 parts of bentonite in 0.5mol / L HCl solution for 3 hours, neutralize with 0.5mol / L NaOH to adjust pH to 7.0-7.1, filter, collect filter residue, rinse filter residue with water 3-5 times, then dried, crushed, and passed through a 100-mesh sieve to obtain bentonite refined soil; after drying the obtained bentonite refined soil, put it into 1.0mol / L LiCl solution, stir for 5 hours, and precipitate, filter, wash, Dry to obtain lithium-based bentonite;

[0023] (2) Preparation method: 1) Put 1 part of lithium-based bentonite into a blender, add 1 part of water while stirring, fully stir to make a paste, and let it stand for 12 hours;

[0024] 2) Heat the paste-like lithium bentonite obt...

Embodiment 2

[0028] A dust suppressant:

[0029] (1) Raw materials: 3 parts of carboxymethyl cellulose, 4 parts of polyacrylamide, 2 parts of hydroxypropyl methylcellulose, 2 parts of lithium bentonite, 10 parts of glycerin and 979 parts of water;

[0030] The preparation method of lithium-based bentonite: Soak 10 parts of bentonite in 0.6mol / L HCl solution for 3 hours, neutralize with 0.8mol / L NaOH to adjust pH to 7.1-7.2, filter, collect filter residue, rinse filter residue with water 3-5 times, then dried, crushed, and passed through a 100-mesh sieve to obtain bentonite refined soil; after drying the obtained bentonite refined soil, put it into a 1.2mol / L LiCl solution, stir for 6 hours, and precipitate, filter, wash, Dry to obtain lithium-based bentonite;

[0031] (2) Preparation method: 1) Put 2 parts of lithium-based bentonite into a blender, add 2 parts of water while stirring, fully stir to make a paste, and let it stand for 12 hours;

[0032] 2) Heat the pasty lithium-based bent...

Embodiment 3

[0036] A dust suppressant:

[0037] (1) Raw materials: 5 parts of carboxymethyl cellulose, 5 parts of polyacrylamide, 3 parts of hydroxypropyl methylcellulose, 4 parts of lithium bentonite, 10 parts of glycerin and 973 parts of water;

[0038]The preparation method of lithium-based bentonite: Soak 10 parts of bentonite in 0.8mol / L HCl solution for 4 hours, neutralize with 0.8mol / L NaOH to adjust pH to 7.2-7.3, filter, collect filter residue, rinse filter residue with water 3-5 times, then dried, crushed, and passed through a 120-mesh sieve to obtain bentonite refined soil; after drying the obtained bentonite refined soil, put it into 1.6mol / L LiCl solution, stir for 7 hours, and precipitate, filter, wash, Dry to obtain lithium-based bentonite;

[0039] (2) Preparation method: 1) Put 4 parts of lithium-based bentonite into a blender, add 4 parts of water while stirring, fully stir to make a paste, and let it stand for 14 hours;

[0040] 2) Heat the paste-like lithium bentonit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com