Antibacterial composition and preparation method and application thereof

A composition and technology of Antrodia camphorata mycelium, applied in the directions of botanical equipment and methods, detergent compositions, synthetic soap compositions, etc., can solve problems such as dry and rough skin, and achieve improved bactericidal, antiviral, and strong bactericidal effects. , Prevent dry and rough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

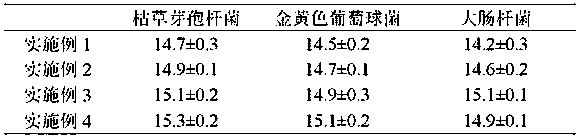

Examples

preparation example Construction

[0022] The preparation method of antibacterial composition of the present invention may further comprise the steps:

[0023] A. Mix olive oil, coconut oil, palm oil and tallow in the formula and heat to 40~45°C, add sodium hydroxide and stir continuously until it becomes a thick paste to obtain soap liquid;

[0024] B. Add antrodia camphorata fermented mycelium powder and EDTA in the formula ratio in sequence to the soap liquid, and ultrasonically disperse to obtain the target antibacterial composition.

[0025] The ultrasonic frequency of ultrasonic dispersion in step B is 15000-25000 Hz.

[0026] The application of the bacteriostatic composition of the present invention is the application of the bacteriostatic composition in the preparation of daily chemicals.

[0027] The application of the antibacterial composition in the preparation of scented soap, the preparation method is to inject the antibacterial composition into a mould, ventilate and let it stand for cooling and ...

Embodiment 1

[0034] A kind of Antrodia camphorata fermented mycelium soap, comprising the following components by weight percentage: Antrodia camphorata fermented mycelium powder 11%, olive oil 30%, coconut oil 11%, palm oil 12%, butter 6%, sodium hydroxide 9 %, chelating agent EDTA 0.1%, and deionized water as the balance.

[0035] The Antrodia camphorata fermented mycelium powder is obtained by culturing in conventional potato liquid medium for 25 days, conventionally filtering, vacuum-drying and superfine pulverization. The vacuum drying temperature is 45°C. The ultrafine pulverization temperature is 4°C. The ultrafine pulverization time is 15 minutes.

[0036] The processing technology of this antrodia camphorata fermented mycelium soap comprises the following steps:

[0037] (1) Mix olive oil, coconut oil, palm oil, and butter and heat to 40°C, then add sodium hydroxide and stir continuously until the soap liquid becomes a thick paste;

[0038] (2) Add Antrodia camphorata fermente...

Embodiment 2

[0041] A kind of Antrodia camphorata fermented mycelium soap, comprising the following components by weight percentage: Antrodia camphorata fermented mycelium powder 13%, olive oil 23%, coconut oil 12%, palm oil 14%, butter 9%, sodium hydroxide 9 %, chelating agent EDTA 0.2%, and deionized water as the balance.

[0042] The Antrodia camphorata fermented mycelium powder is obtained by culturing in conventional potato liquid medium for 25 days, conventionally filtering, vacuum-drying and superfine pulverization. The vacuum drying temperature is 45°C. The ultrafine pulverization temperature is 4°C. The ultrafine pulverization time is 10 minutes.

[0043] The processing technology of this antrodia camphorata fermented mycelium soap comprises the following steps:

[0044] (1) Mix olive oil, coconut oil, palm oil, and butter and heat to 45°C, then add sodium hydroxide and stir continuously until the soap liquid becomes a thick paste;

[0045] (2) Add Antrodia camphorata fermente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com