sauce-flavored liquor

A technology for Maotai-flavor liquor and distiller's grains, which is applied in the field of wine making, can solve problems such as waste, and achieve the effects of reducing dosage, facilitating growth and reproduction, and having a rich and mellow wine quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The sauce-flavored liquor is prepared by the following process:

[0062] S1 Weighing raw materials: Weigh five-grain raw materials, high-temperature Daqu (commercially available, provided by Jining Guolong Materials Co., Ltd.), distiller’s grains and chaff, wherein the weight ratio of five-grain raw materials, high-temperature Daqu, distiller’s grains, and chaff is 1: 0.03:2:0.27; the five-grain raw material is composed of the following proportions: 25wt% wheat, 10wt% corn, 7wt% glutinous rice, 5wt% rice, and the balance is sorghum;

[0063] S2 Wuliang moistening material: crush sorghum to 4 petals to obtain sorghum petals; add water at 80°C with 25% of the total weight of five grain raw materials to sorghum petals, and mix evenly to obtain a mixture; mix wheat, corn, glutinous rice, and rice Crush into 2 cloves respectively, mix well, and cover the mixture; after standing for 40 minutes, add 30% of the total weight of Wuliang raw materials into water at 80°C, mix well,...

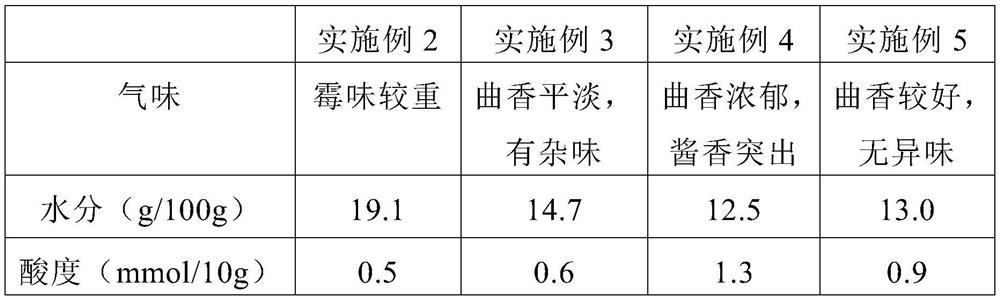

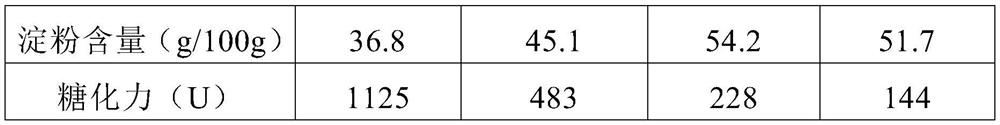

Embodiment 2~5

[0070] The sauce-flavored liquor is prepared by the following process:

[0071] S1 Weighing raw materials: Weigh five-grain raw materials, high-temperature Daqu, distiller's grains and rice hulls, wherein the weight ratio of five-grain raw materials, high-temperature Daqu, distiller's grains, and rice hulls is 1:0.03:2:0.27; the five-grain raw materials are composed of the following Proportion composition: wheat 25wt%, corn 10wt%, glutinous rice 7wt%, rice 5wt%, the balance is sorghum;

[0072] S2 Wuliang moistening material: crush sorghum to 4 petals to obtain sorghum petals; add water at 80°C with 25% of the total weight of five grain raw materials to sorghum petals, and mix evenly to obtain a mixture; mix wheat, corn, glutinous rice, and rice Crush into 2 cloves respectively, mix well, and cover the mixture; after standing for 40 minutes, add 30% of the total weight of Wuliang raw materials into water at 80°C, mix well, and obtain Wuliang moistening material;

[0073] S3 s...

Embodiment 6~8

[0094] The sauce-flavored liquor is prepared by the following process:

[0095] S1 Weighing raw materials: Weigh five-grain raw materials, high-temperature Daqu, distiller's grains and rice hulls, wherein the weight ratio of five-grain raw materials, high-temperature Daqu, distiller's grains, and rice hulls is 1:0.03:2:0.27; the five-grain raw materials are composed of the following Proportion composition: wheat 25wt%, corn 10wt%, glutinous rice 7wt%, rice 5wt%, the balance is sorghum;

[0096] S2 Wuliang moistening material: crush sorghum to 4 petals to obtain sorghum petals; add water at 80°C with 25% of the total weight of five grain raw materials to sorghum petals, and mix evenly to obtain a mixture; mix wheat, corn, glutinous rice, and rice Crush into 2 cloves respectively, mix well, and cover the mixture; after standing for 40 minutes, add 30% of the total weight of Wuliang raw materials into water at 80°C, mix well, and obtain Wuliang moistening material;

[0097] S3 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com