Partition test system and method of cold start current density and temperature of fuel cell

A cold-start current, fuel cell technology, used in current density measurement, thermometers, thermometers with electrical/magnetic components directly sensitive to heat, etc., can solve the difficulty of increasing measurement, immature, and expensive production problem, to achieve the effect of accurate resistance value and simplified operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following examples further illustrate the technical solutions of the present invention, but are not intended to limit the protection scope of the present invention.

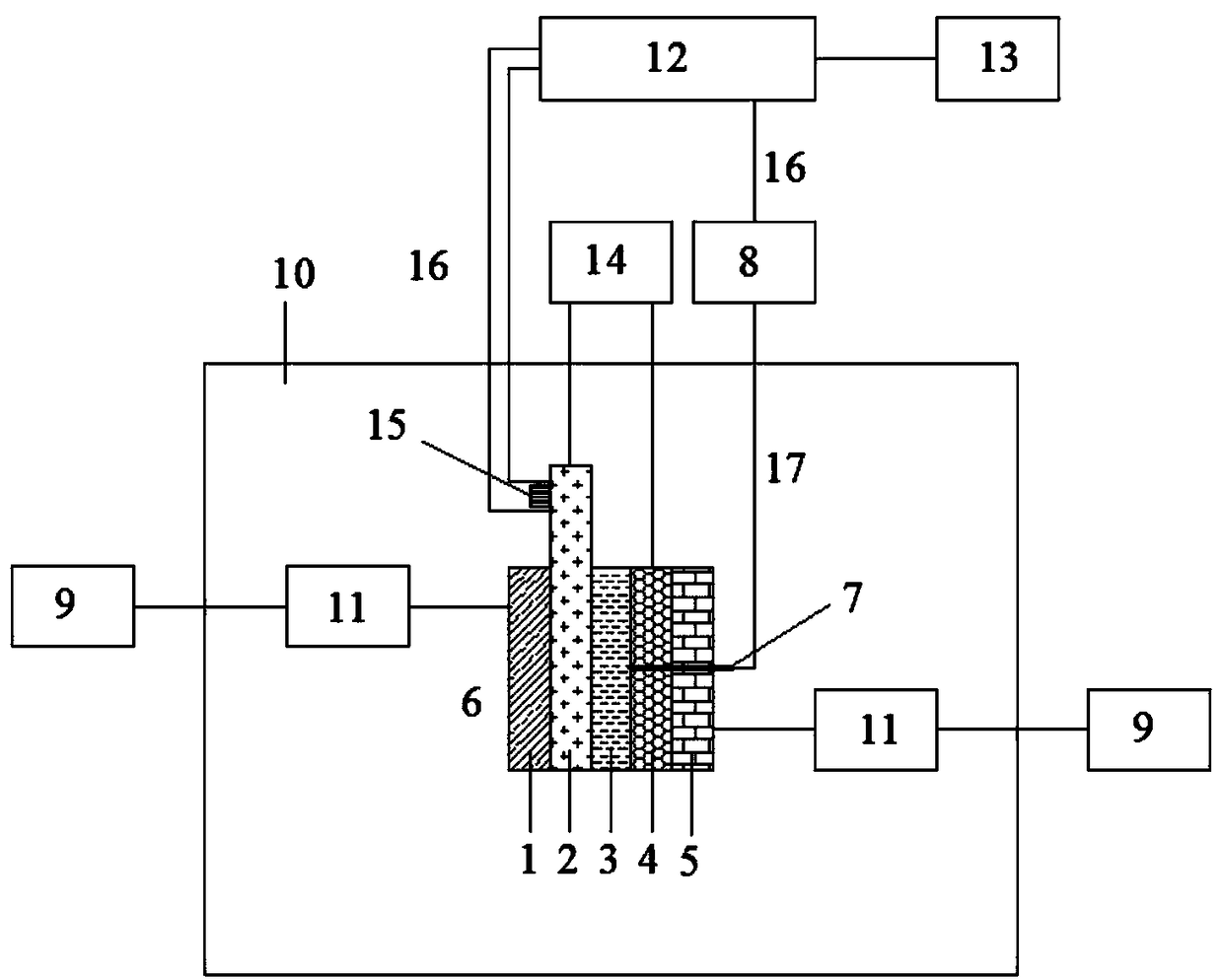

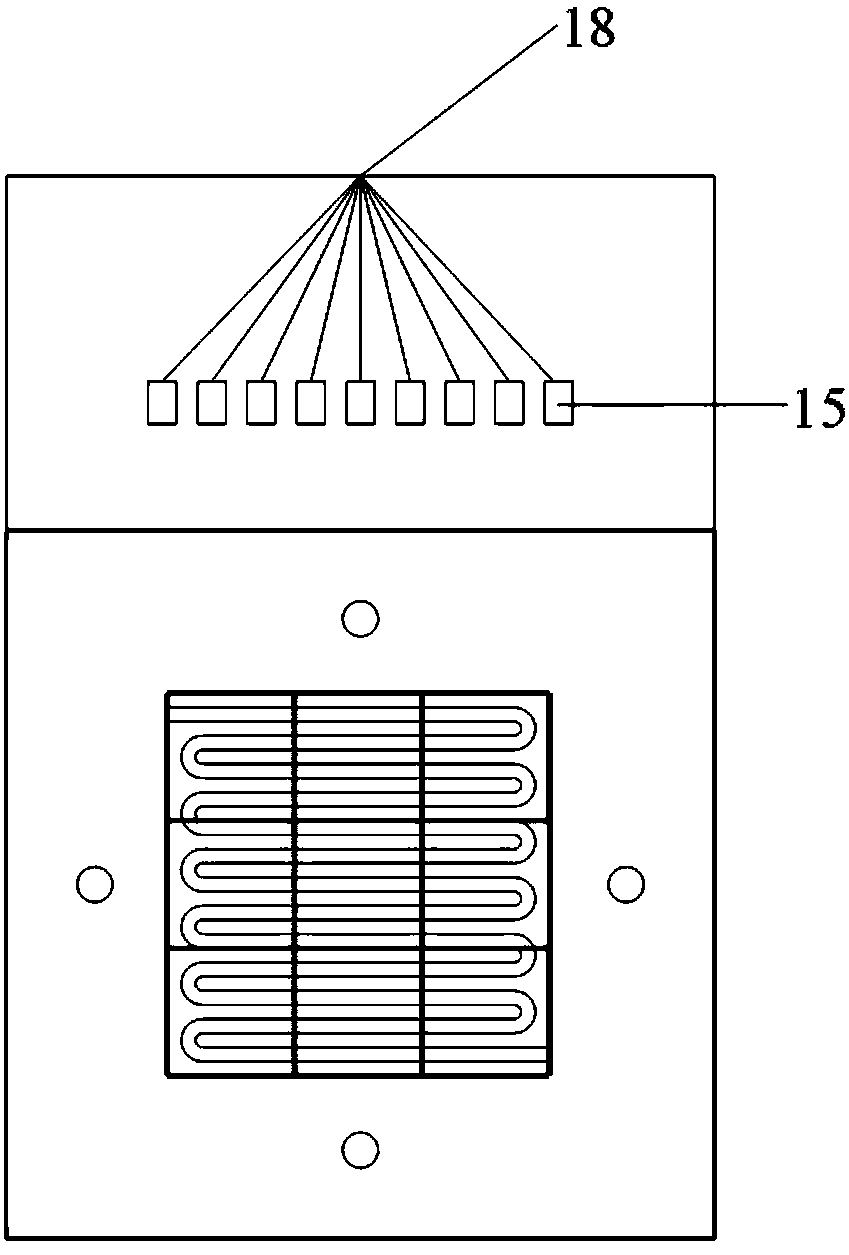

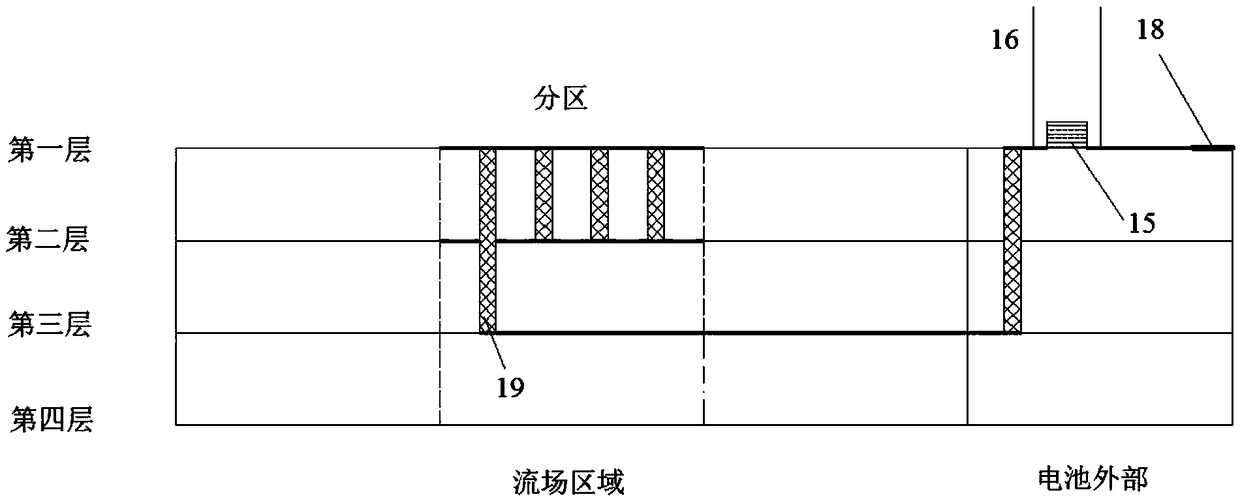

[0033] Such as figure 1 As shown, a fuel cell cold start current density and temperature zone test system, the fuel cell 6 includes an anode end plate 1, a current density test plate 2, a membrane electrode assembly 3, a cathode flow field plate 4, a cathode end plate 5. The current density test plate 2 is placed on the anode of the battery, and assembled into a fuel cell in the order of the anode end plate 1, the current density test plate 2, the membrane electrode assembly 3, the cathode flow field plate 4, and the cathode end plate 5 6. Both the cathode flow field plate 4 and the cathode end plate 5 have sockets, and the test system includes a fuel cell 6, a thermocouple 7, an ice bath 8, an air intake system module 9, and a high and low temperature cooling box 10. Cooling pipe 11, data acquisition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com