GaN-based T-type gate high-frequency device, preparation method thereof and application thereof

A high-frequency, device technology, applied in the field of GaN-based T-gate high-frequency devices and its preparation, can solve the problems of small gate length, lower mobility under the gate, and limit the speed of pattern exposure, etc., to reduce parasitic capacitance , improve frequency characteristics, and solve the effect of low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] An embodiment of the present invention provides a method for manufacturing a GaN-based T-gate high-frequency device, including:

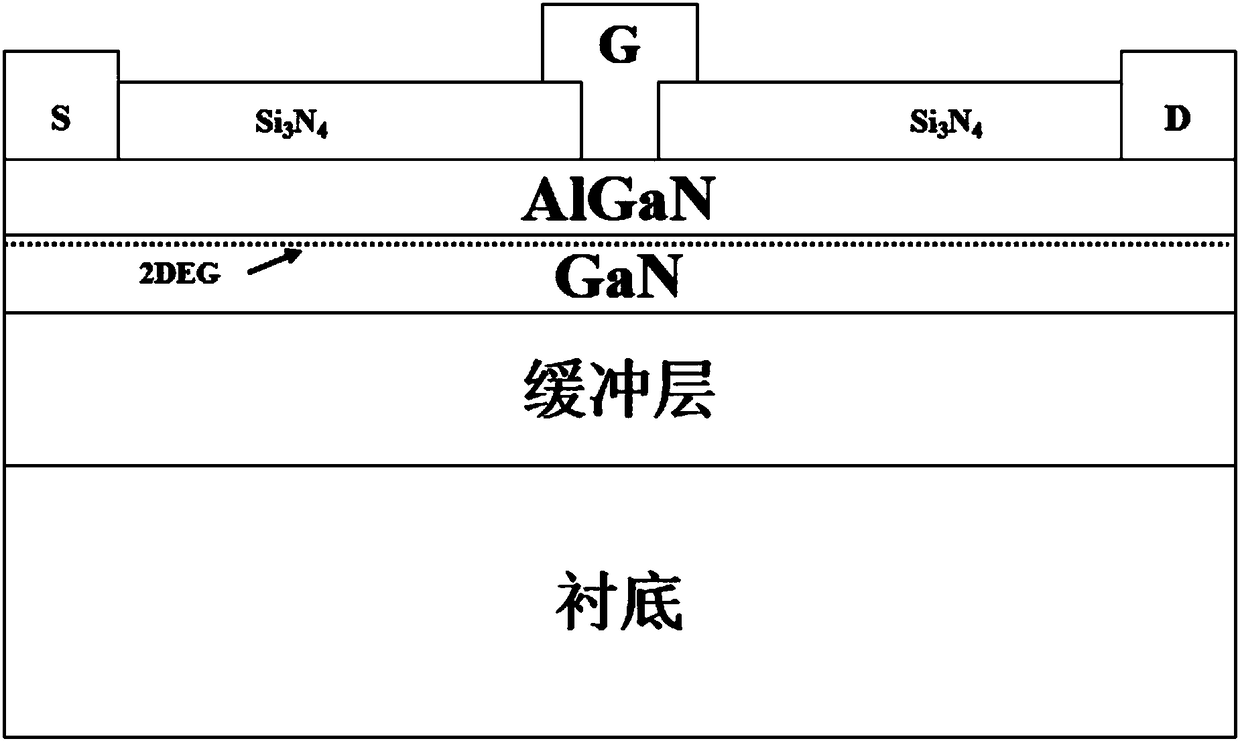

[0064] providing a heterojunction comprising a first semiconductor and a second semiconductor, the second semiconductor being formed on the first semiconductor and having a bandgap wider than that of the first semiconductor, the heterojunction having two-dimensional electrons formed therein gas;

[0065] Forming a P-type semiconductor and a high-resistance semiconductor on the heterojunction, the P-type semiconductor is located in the region under the gate, and the high-resistance semiconductor is located between the P-type semiconductor and any one of the source and drain;

[0066] Make the source, drain and gate, connect the gate to the P-type semiconductor, the length of the gate is greater than the length of the P-type semiconductor, and the P-type semiconductor is used to deplete the two-dimensional electrons in the region under the gate...

Embodiment 1

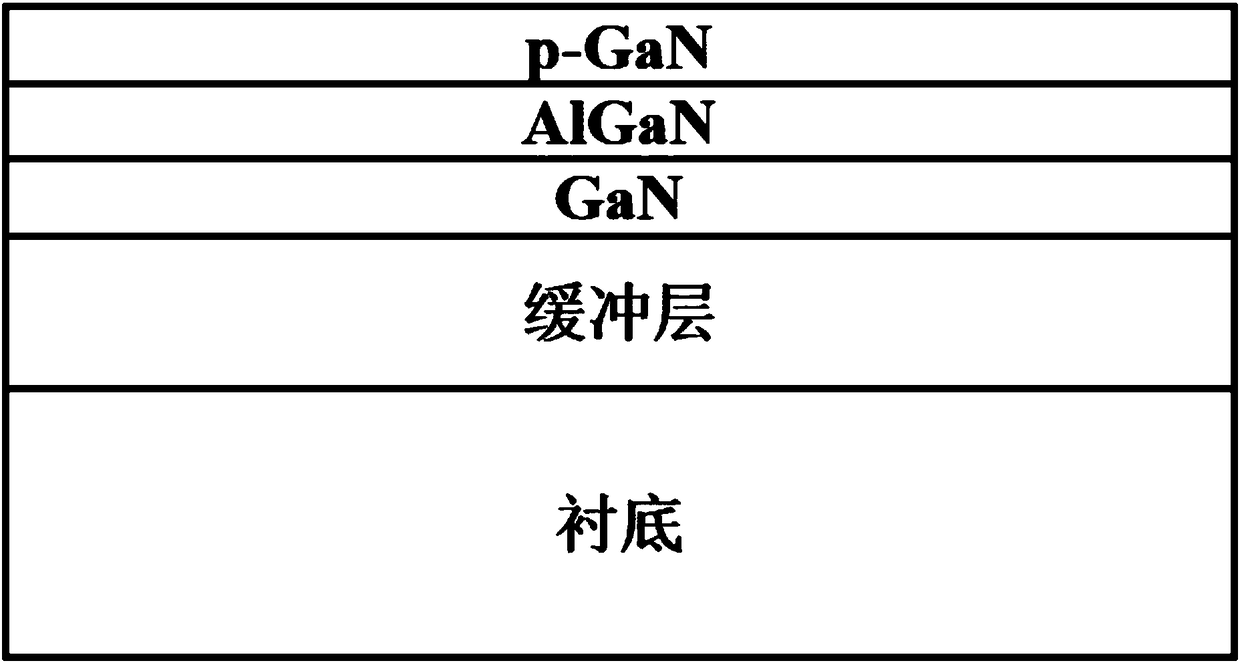

[0092] 1) Using metal organic compound chemical vapor deposition (MOCVD) to grow such as figure 2The device structure shown. The substrate material is Si, with a thickness of 200 μm to 1500 μm, preferably 400 μm; the material of the buffer layer is high resistance GaN or high resistance AlGaN, with a thickness of 1000 nm to 5000 nm, preferably 4200 nm; AlGaN / GaN heterostructure (GaN can be replaced by GaAs or other materials that can provide heterojunctions, AlGaN can be replaced by AlInN, AlGaAs or InGaAs or other materials that can provide heterojunctions) GaN thickness is 100nm to 500nm, preferably 260nm; AlGaN thickness is 15nm to 30nm, preferably 18nm, wherein the content of the Al component is 15-30wt%, preferably 18wt%; the p-type semiconductor material is p-GaN, with a thickness of 50nm-100nm, preferably 70nm;

[0093] 2) by low-pressure chemical vapor deposition (LPCVD) in the figure 2 Insulating Si deposited on the surface of the device structure shown (i.e., on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com