A kind of methane gas sensor and preparation method of tin mud loaded palladium in tin plating process

A methane gas and sensor technology, applied in the direction of material electrochemical variables, etc., can solve the problems of tin sludge waste, achieve good response-recovery characteristics, improve gas sensing performance, and enhance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

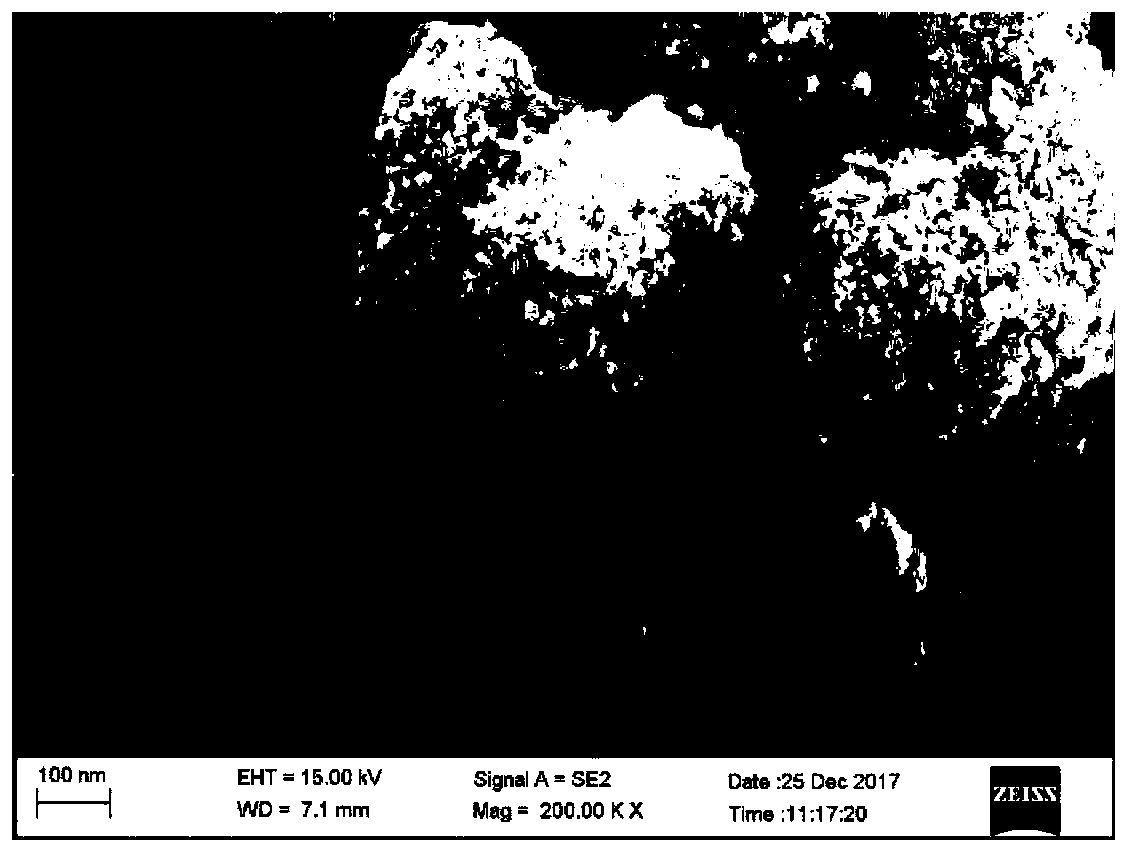

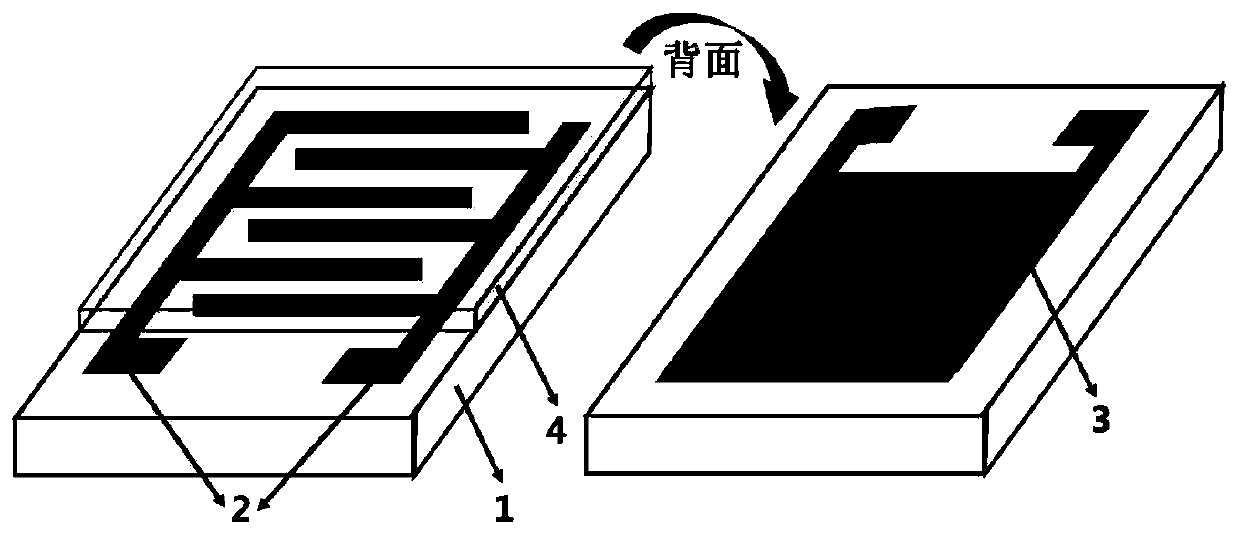

[0031] Example 1 Preparation of methane gas sensor with palladium supported on tin mud

[0032] Take 5g of washed and dried tin sludge in a ball mill jar, add 8g of polyethylene glycol 400 and 2g of polyvinyl alcohol for mechanical ball milling, and keep the mixture obtained from ball milling in an autoclave at 160°C for 4 hours, then cool it out And sintering in the air at 500° C. for 3 hours to obtain a porous nano-solid modified by tin mud. 0.1g of PdCl 2 Dissolve in a mixed solution of 10ml deionized water and absolute ethanol, add 1g of porous nano-solid, and 10mg of antimony trioxide, stir evenly for 3h, then heat-treat in air at 450°C for 2h to obtain PdCl 2 Loaded porous nano-solid gas-sensing material. PdCl 2 The loaded porous nano-solid material is mixed with deionized water at a mass ratio of 2:1, ground to form a slurry and uniformly coated on a ceramic substrate, and then dried naturally for electrode welding to obtain a methane gas sensor.

Embodiment 2

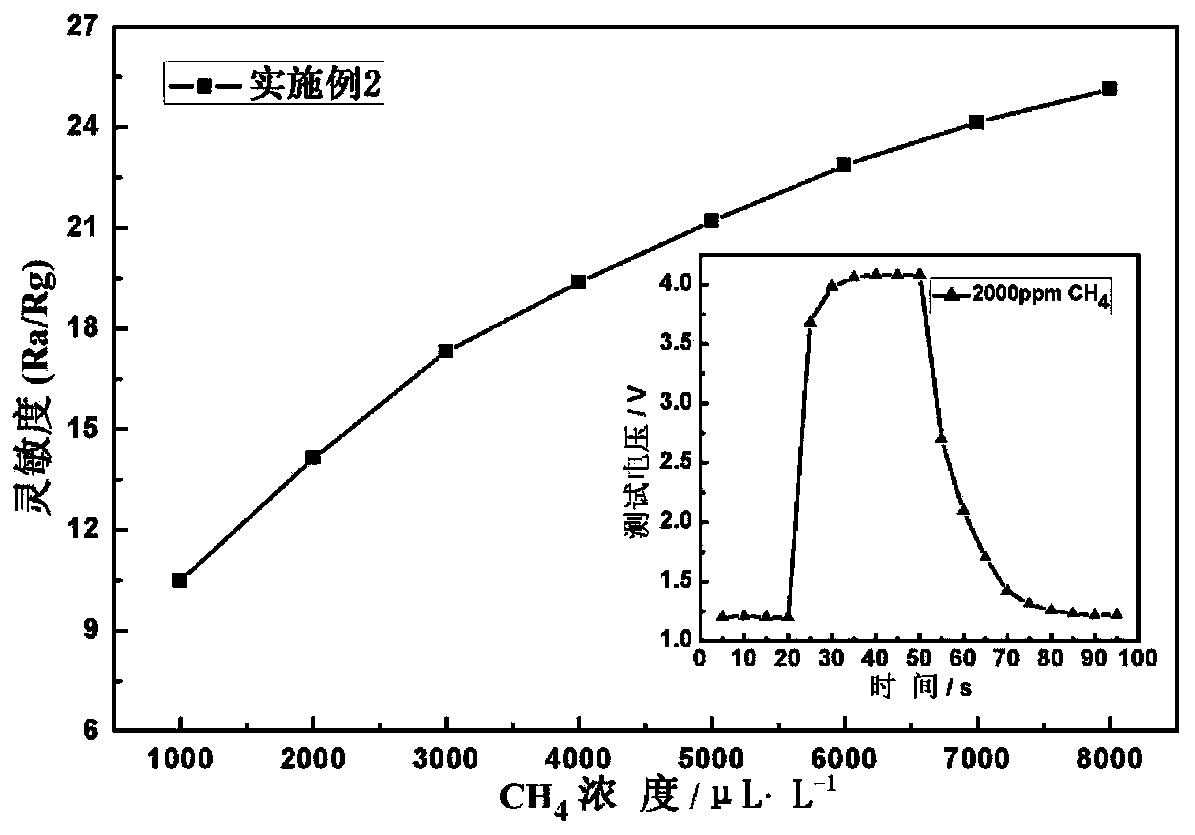

[0033] Example 2 Preparation of methane gas sensor with palladium supported on tin mud

[0034] Take 5g of washed and dried tin sludge in a ball mill jar, add 8g of polyethylene glycol 400 and 2g of polyvinyl alcohol for mechanical ball milling, keep the mixture obtained by ball milling in an autoclave at a constant temperature of 180°C for 4 hours, then cool it out And sintering in the air at 500° C. for 3 hours to obtain a porous nano-solid modified by tin mud. 0.1g of PdCl 2 Dissolve in a mixed solution of 10ml deionized water and absolute ethanol, add 1g of porous nano-solid, and 10mg of antimony trioxide, stir evenly for 3h, then heat-treat in air at 450°C for 2h to obtain PdCl 2 Loaded porous nano-solid gas-sensing material. PdCl 2 The loaded porous nano-solid material is mixed with deionized water at a mass ratio of 2:1, ground to form a slurry and uniformly coated on a ceramic substrate, and then dried naturally for electrode welding to obtain a methane gas sensor. ...

Embodiment 3

[0035] Example 3 Preparation of methane gas sensor with palladium supported on tin mud

[0036]Take 5g of washed and dried tin sludge in a ball mill jar, add 8g of polyethylene glycol 400 and 2g of polyvinyl alcohol for mechanical ball milling, keep the mixture obtained by ball milling in an autoclave at 200°C for 4 hours, then cool it out And sintering in the air at 500° C. for 3 hours to obtain a porous nano-solid modified by tin mud. 0.1g of PdCl 2 Dissolve in a mixed solution of 10ml deionized water and absolute ethanol, add 1g of porous nano-solid, and 10mg of antimony trioxide, stir evenly for 3h, then heat-treat in air at 450°C for 2h to obtain PdCl 2 Loaded porous nano-solid gas-sensing material. PdCl 2 The loaded porous nano-solid material is mixed with deionized water at a mass ratio of 2:1, ground to form a slurry and uniformly coated on a ceramic substrate, and then dried naturally for electrode welding to obtain a methane gas sensor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com