A kind of preparation method of Jingangteng soft capsule

A technology of soft capsules and diamonds, which is applied in the direction of microcapsules, capsule delivery, and pharmaceutical formulations. It can solve problems such as drying difficulties, achieve good drug quality stability, ensure standard compliance, and increase stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Preparation of King Kongtaw Extract Extract Powder

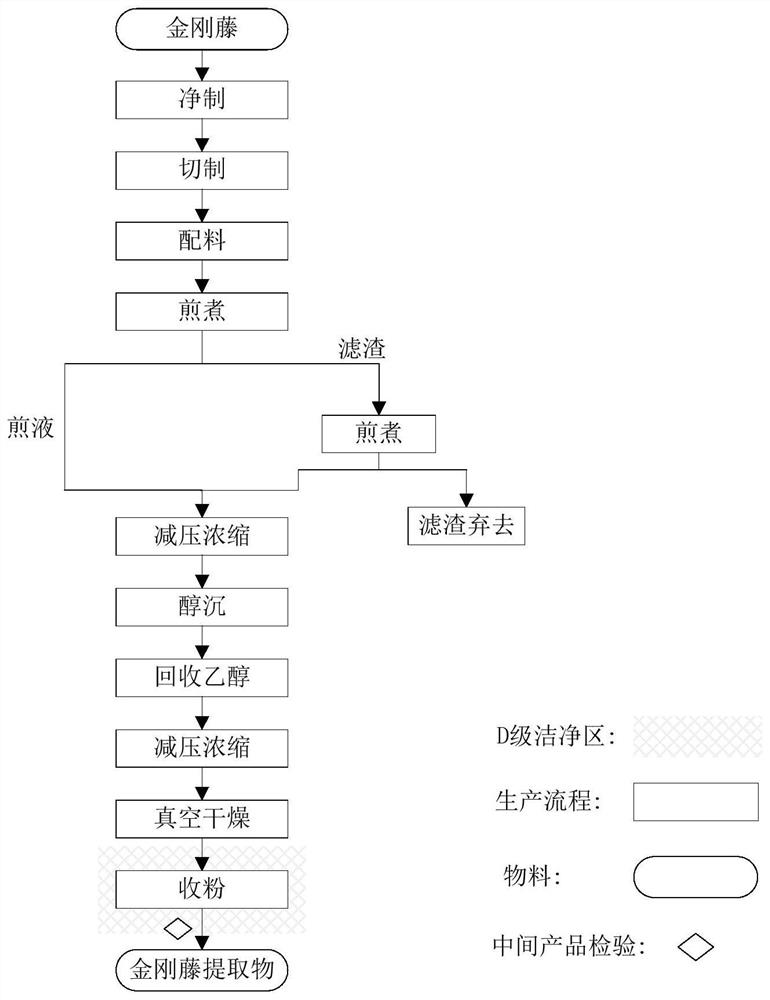

[0046] Such as figure 1 As shown in the process flow, take King Kong Fuji original medicinal material, wash, slice, add 10 times the weight of pure water to decoct and extract twice, combine the extracts, and discard the filter residue. The combined decoctions were concentrated under reduced pressure to 1g decoction / 1g raw medicinal materials, added ethanol, precipitated with alcohol, filtered, concentrated under reduced pressure, and then vacuum-dried at 60°C for 4.5 hours to obtain King Kongteng extract powder (about 380mg~ 440mg; under the premise of meeting the preparation process, 1 part of soybean oil can dilute 1.3 parts of vacuum-dried extract powder and 1 part of spray-dried extract powder), and the water content of the extract powder is ≤1.0%. After passing the inspection, it will be stored for later use.

Embodiment 2

[0051] Preparation of Jingangteng Soft Capsules

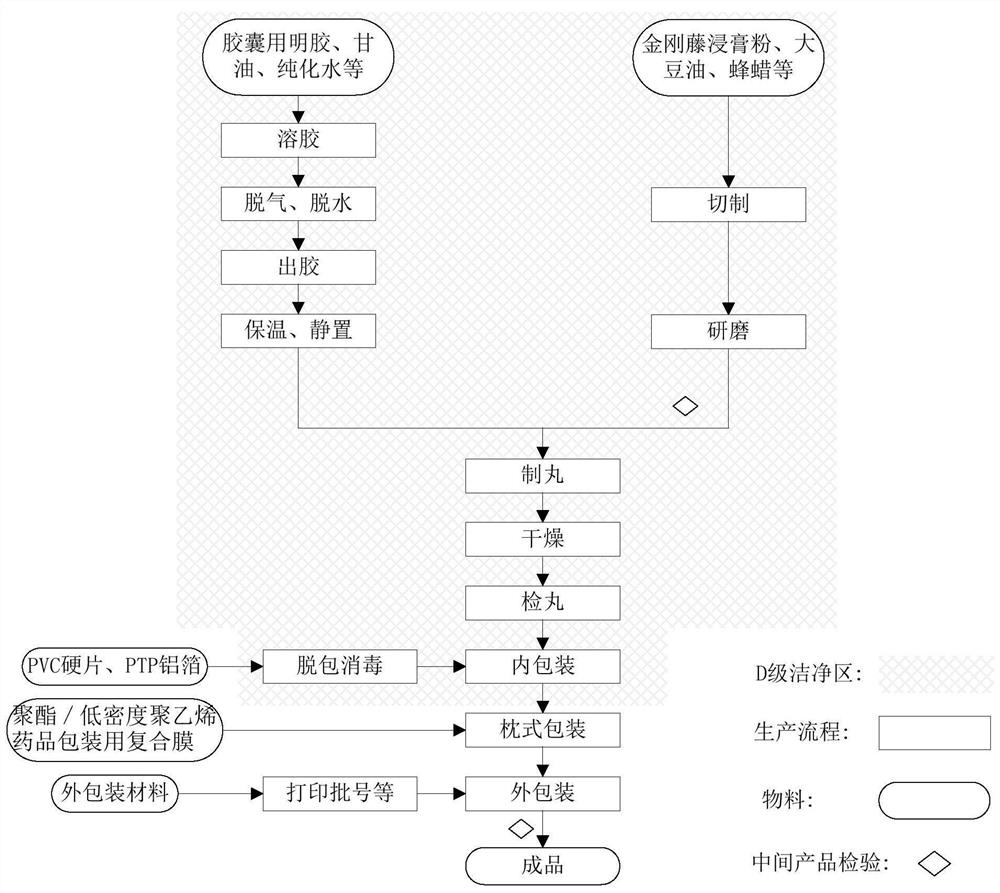

[0052] Such as figure 2 As shown in the technological process, get 40.0 grams of raw materials of King Kongteng extract powder obtained in Example 1, 38.5 grams of soybean oil, 2.0 grams of beeswax, and 1.0 grams of glycine. After the beeswax is chopped, add about 1 / 3 of soybean oil and mix, heat and dissolve Completely, then add the remaining soybean oil, 40.0 grams of King Kongteng extract powder, 3.5 grams of sorbitol, and 1.0 grams of glycine, and grind for 40 minutes to obtain the soft capsule content raw materials, which are set aside. Take 100.0 grams of gelatin, 40.0 grams of glycerin, 90.0 grams of purified water, 10.0 grams of sorbitol, 1.0 grams of glycine, etc. for soft capsules, mix them, heat to 75°C, dissolve completely, vacuum degas and dehydrate, and obtain uniform soft capsule skin raw materials , kept at 60°C for later use. The soft capsule skin of insulation and soft capsule content raw material are mad...

Embodiment 3

[0054] Preparation of Jingangteng Soft Capsules

[0055] Such as figure 2 As shown in the technical process, get 40 grams of diamond vine extract powder raw materials obtained in Example 1, 38.5 grams of soybean oil, 2 grams of beeswax, 3.5 grams of spray lactose, and 1.0 grams of glycine. After chopping the beeswax, add about 1 / 3 Soybean oil is mixed, heated and dissolved completely, then the remaining soybean oil, King Kongteng extract powder, hydrophilic spray lactose, and glycine are added, and ground for 40 minutes, which is the raw material of the soft capsule content and set aside. Take 100.0 grams of gelatin, 40.0 grams of glycerin, 90.0 grams of purified water, 10.0 grams of sorbitol, 1.0 grams of glycine, etc. for soft capsules, mix them, heat to 75 ° C, complete dissolution, vacuum degassing, and dehydration to obtain a uniform soft capsule skin Raw materials, keep warm at 60°C and set aside for later use. The soft capsule skin raw material of heat preservation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com