Method for regulating and controlling crystalline silicon surface corrugated structure based on plasmoid lens effect

A technology of plasma and lens effect, applied in the field of femtosecond laser application, to achieve the effect of improving processing accuracy and controllability, and efficient and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

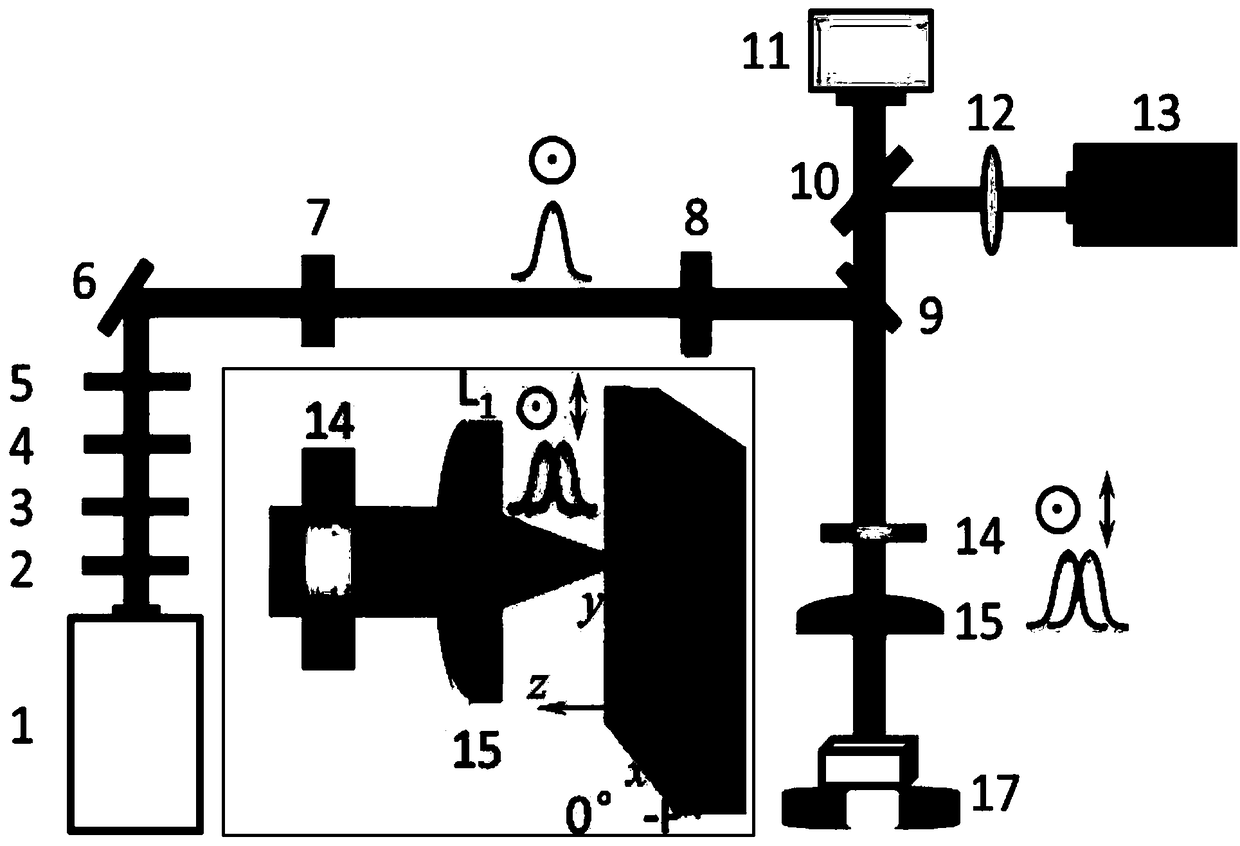

[0037] Taking control of the corrugated structure on the surface of crystalline silicon as an example, using the pre-plasma-like nanostructure construction of the present invention, the incident laser polarization state regulation method, the incident fundamental frequency femtosecond laser pulse is linearly polarized, and the specific processing steps are as follows:

[0038] Adjust the optical path to ensure that the incident direction of the laser is perpendicular to the surface of the processed sample;

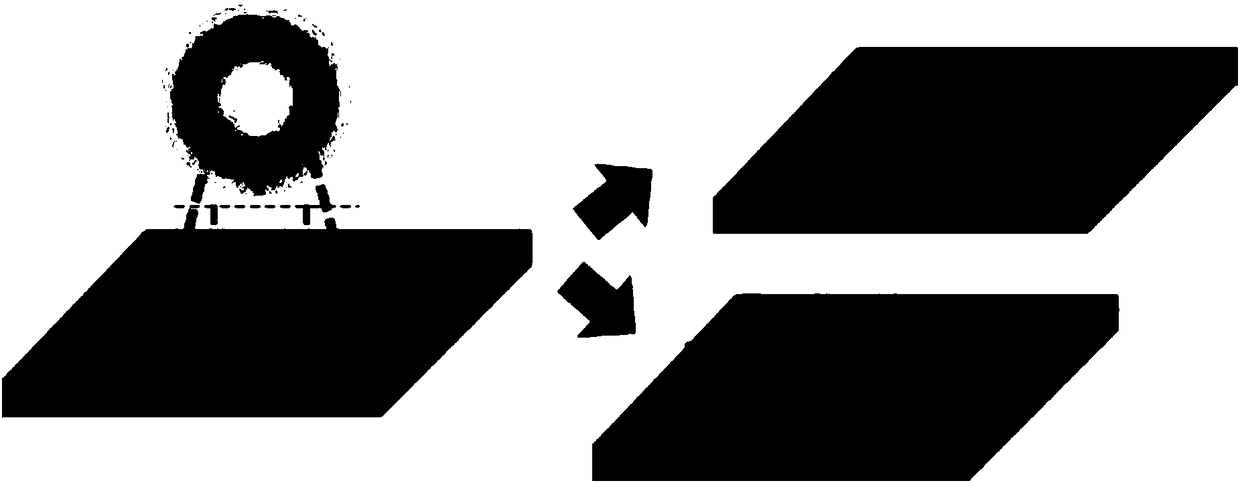

[0039] (1) Sample preparation: In this embodiment, a 20nm thick gold film is plated on a substrate silicon sample of 10mm×10mm×1mm by magnetron sputtering;

[0040] (2) Light field shaping of the incident fundamental frequency femtosecond laser pulse: the frequency doubling crystal 14 is placed in the optical path, and the angle of the frequency doubling crystal 14 is adjusted to maximize the frequency doubling efficiency. After the fundamental frequency femtosecond laser p...

Embodiment 2

[0047] Taking control of the corrugated structure on the surface of crystalline silicon as an example, using the pre-plasma-like nanostructure construction of the present invention, the incident laser polarization state regulation method, the incident fundamental frequency femtosecond laser pulse used is circular polarization state, and the specific processing steps are as follows:

[0048] Other steps are identical with embodiment 1, and difference is: before step (4) energy regulation is carried out, add quarter-wave plate 5 in optical path, adjust quarter-wave plate 5, make wave plate optical axis direction and The included angle of the original laser polarization direction is 45° to obtain circularly polarized femtosecond laser pulses.

[0049] In step (7), the processing is carried out under the condition of circularly polarized femtosecond laser pulses, and a single circularly polarized femtosecond laser pulse is used to irradiate the plasmonic gold nanoring structure, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com