Preparation method of graphene

A technology of graphene and graphite powder, which is applied in the field of chemical synthesis materials, can solve the problems of high preparation cost, difficult disposal of waste liquid, dangerous preparation method, etc., and achieve the effect of changing thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] a. Weigh 2.0g gum arabic and dissolve it in 50ml deionized water and heat it with constant stirring until it is completely dissolved to obtain a light yellow solution;

[0019] b. Take 5 ml light yellow gum arabic solution, add to 500 ml containing 300g ZrO with a radius of 2 mm 2 Ball milled at 300rpm for 5 min in a polytetrafluoroethylene tank of the pellets, so that the gum arabic solution adhered to the surface of the ZrO2 pellets as much as possible. Add 0.5g of graphite powder (99.95%), ball mill for 10h under the same conditions, then add 50 ml of deionized water, continue ball milling for 10min, take out the solution and centrifuge at 3000 rpm for 60min. Removal of the precipitate yielded a uniform and stable black solution.

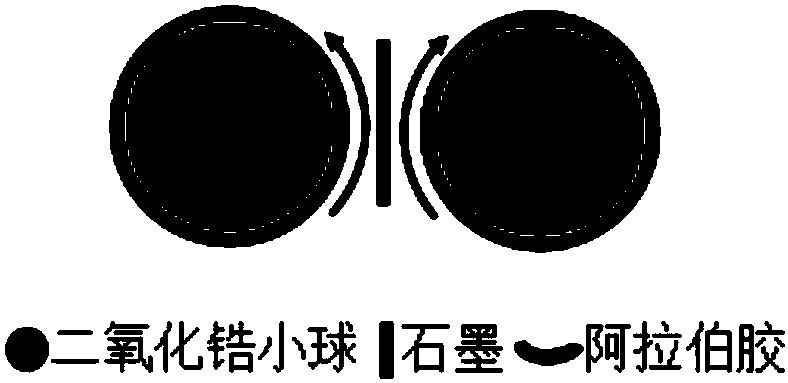

[0020] figure 1 Shown is the schematic diagram of ball milling. By covering the surface of the ball with a layer of viscous gum arabic solution, and then adding graphite, the graphite is peeled off during the continuous rolling of many ...

Embodiment 2

[0025] a. Weigh 2.0g of gum arabic and dissolve it in 50ml of deionized water, stir and heat until completely dissolved to obtain a light yellow solution.

[0026] b. Take 8 ml light yellow gum arabic solution, add to 500 ml containing 300g ZrO with a radius of 4 mm 2 Ball milled at 300 rpm for 5 min in a polytetrafluoroethylene tank to make the gum arabic solution adhere to the ZrO2 as much as possible. 2 surface of the ball. Add 0.5g of graphite powder (99.95%), ball mill for 10 h under the same conditions, then add 50 ml of deionized water, continue ball milling for 10 min, take out the solution and centrifuge at 4000 rpm for 60 min. Removal of the precipitate yielded a uniform and stable black solution.

Embodiment 3

[0028] a. Weigh 3.0g gum arabic and dissolve it in 50ml deionized water and heat it with constant stirring until it is completely dissolved to obtain a light yellow solution.

[0029] b. Take 4 ml light yellow gum arabic solution, add to 500 ml containing 300g ZrO with a radius of 2mm 2 Ball milled at 300 rpm for 5 min in a polytetrafluoroethylene tank to make the gum arabic solution adhere to the ZrO2 as much as possible. 2 surface of the ball. Add 0.5g of graphite powder (99.95%), ball mill for 8 h under the same conditions, then add 50 ml of deionized water, continue ball milling for 10 min, take out the solution and centrifuge at 3000 rpm for 60 min. Removal of the precipitate yielded a uniform and stable black solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com