Manufacturing method of film with controllable thermal conductivity and micro-nano structure

A technology of micro-nano structure and manufacturing method, which is applied in the fields of thin film manufacturing and micro-nano processing, can solve the problems of reducing and flexibly regulating the increase of thermal conductivity, and achieves the effect of high controllability and high success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

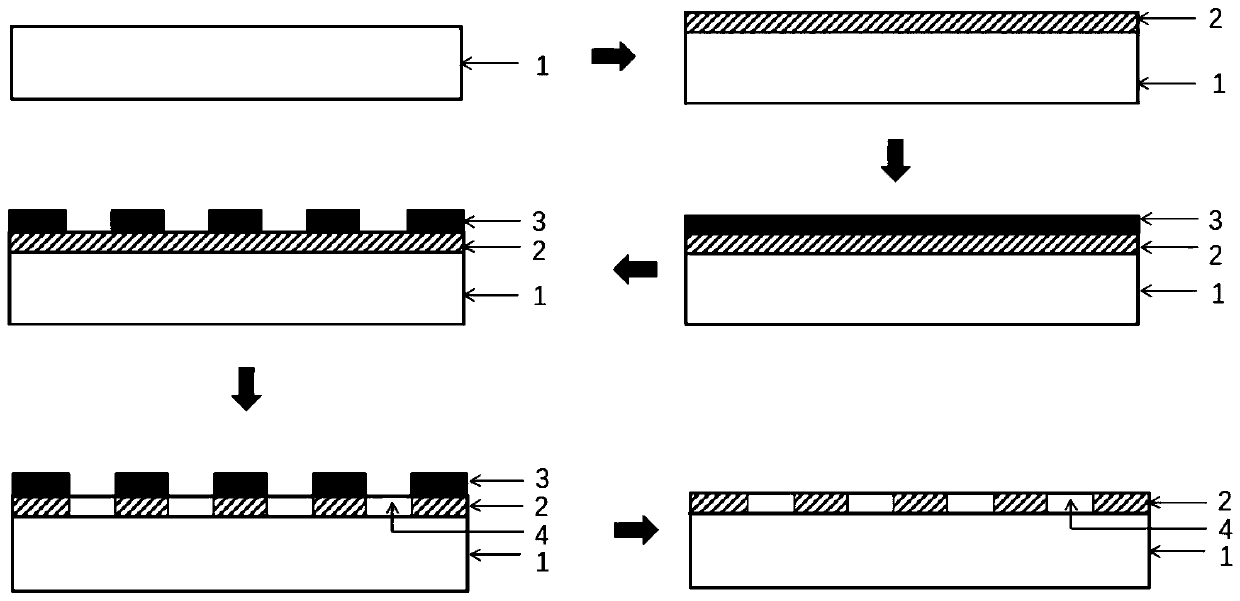

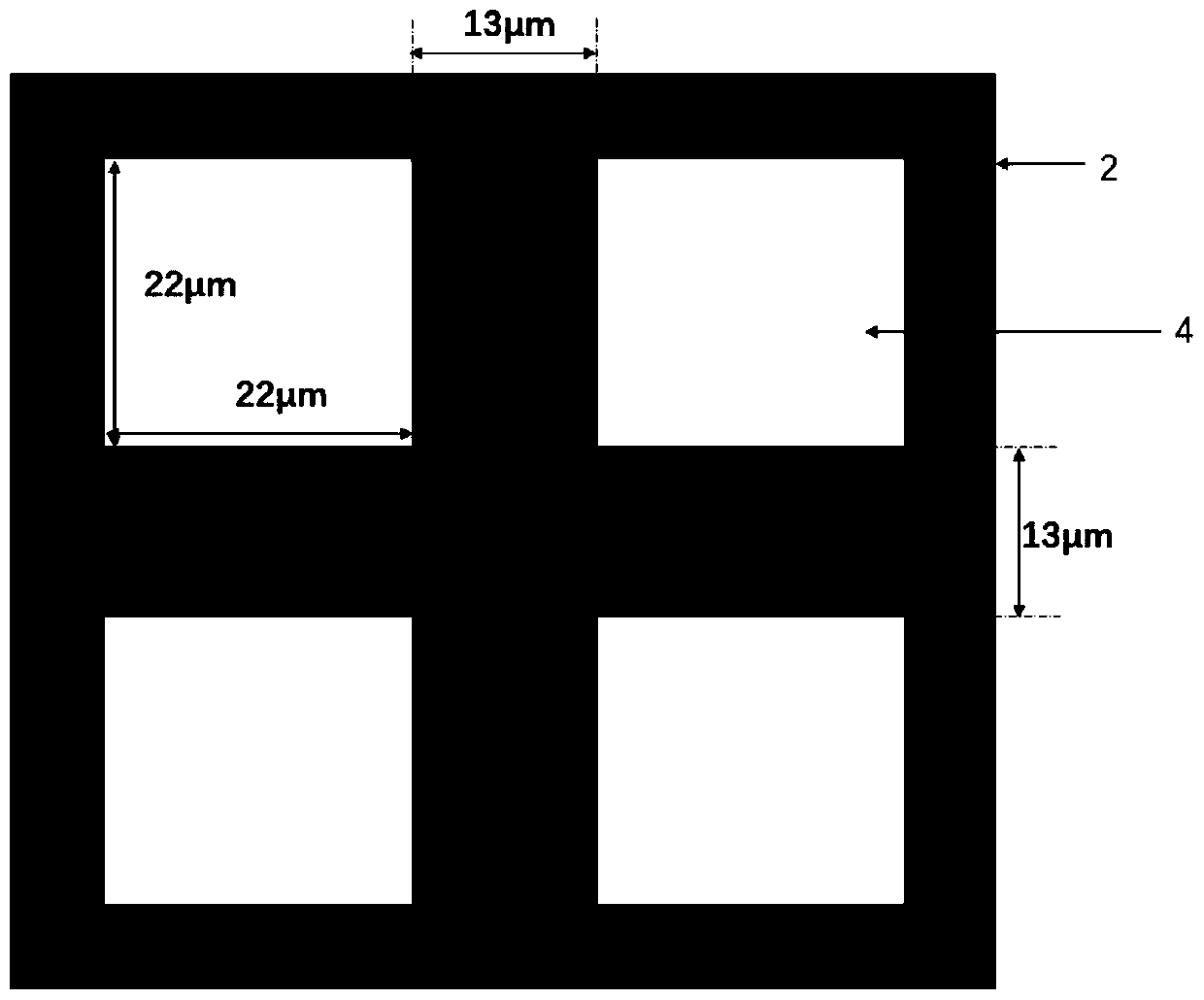

[0031] Embodiment 1: Taking the preparation of polyimide (PI) solid film as an example, adopt the preparation method of the present invention to reduce the thermal conductivity of PI solid film 2, and its technological process is as follows figure 1 As shown, the specific production method is as follows:

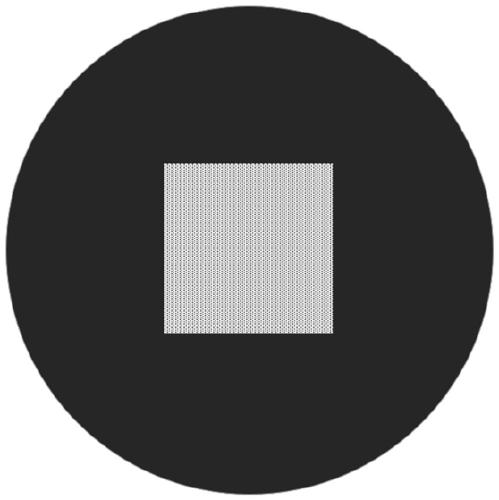

[0032] Step 1: Select (100) crystal-oriented N-type single-sided polished circular silicon wafer 1 as the substrate, the thickness of the silicon wafer 1 is 500 μm, the diameter is 4 inches, and the polished surface is used as the operation surface. Clean the substrate operation surface: use acetone, alcohol, and deionized water to ultrasonically clean the substrate for 10 minutes in sequence, and use nitrogen to dry the operation surface after cleaning.

[0033] Step 2: Prepare a circular PI solid film 2 with a diameter of 4 inches and a thickness of 0.5 μm on the operating surface of the silicon wafer 1 by using a homogenizer. Solid content of PI solution: 12%, viscosity ...

Embodiment 2

[0038] Embodiment 2: the comparative example of embodiment 1

[0039] Step 1: Select (100) crystal-oriented N-type single-sided polished circular silicon wafer 1 as the substrate, the thickness of the silicon wafer 1 is 500 μm, the diameter is 4 inches, and the polished surface is used as the operation surface. Clean the substrate operation surface: use acetone, alcohol, and deionized water to ultrasonically clean the substrate for 10 minutes in sequence, and use nitrogen to dry the operation surface after cleaning.

[0040] Step 2: Prepare a circular PI solid film 2 with a diameter of 4 inches and a thickness of 0.5 μm on the operating surface of the silicon wafer 1 by using a homogenizer. Solid content of PI solution: 12%, viscosity 300-400cp; speed of homogenizer: pre-spin coating 800r / min, homogenization time 60s; fast spin coating 4000r / min, homogenization time 180s. After the spin coating, the PI solid film 2 is heat-treated, and the specific parameters are: bake at 100...

Embodiment 3

[0041] Embodiment 3: Taking the preparation of a silicon oxide solid film as an example, the preparation method of the present invention is used to improve the thermal conductivity of the silicon oxide solid film, and its process flow is as follows Figure 4 As shown, the specific production method is as follows:

[0042] Step 1: Select (100) crystal-oriented N-type single-sided polished circular silicon wafer 1 as the substrate, the thickness of the silicon wafer 1 is 500 μm, the diameter is 4 inches, and the polished surface is used as the operation surface. Clean the substrate operation surface: use acetone, alcohol, and deionized water to ultrasonically clean the substrate for 10 minutes in sequence, and use nitrogen to dry the operation surface after cleaning.

[0043] Step 2: Use the magnetron sputtering process to sputter a circular silicon oxide solid film 5 with a diameter of 4 inches and a thickness of 300 nm on the surface of the silicon wafer 1, with a sputtering r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com