Preparation method of liquid metal non-stick layer and utensil not sticking to liquid metal

A technology of liquid metal and utensils, applied in coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve the problems of small selection of utensil materials, poor non-stick structure stability, and short duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

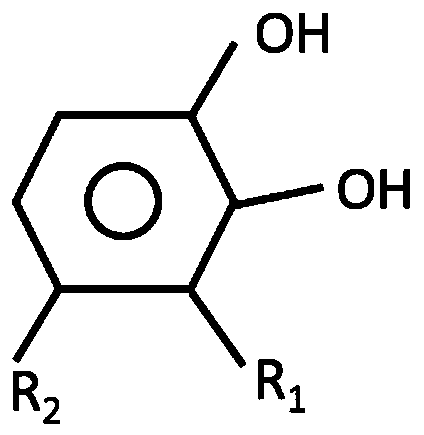

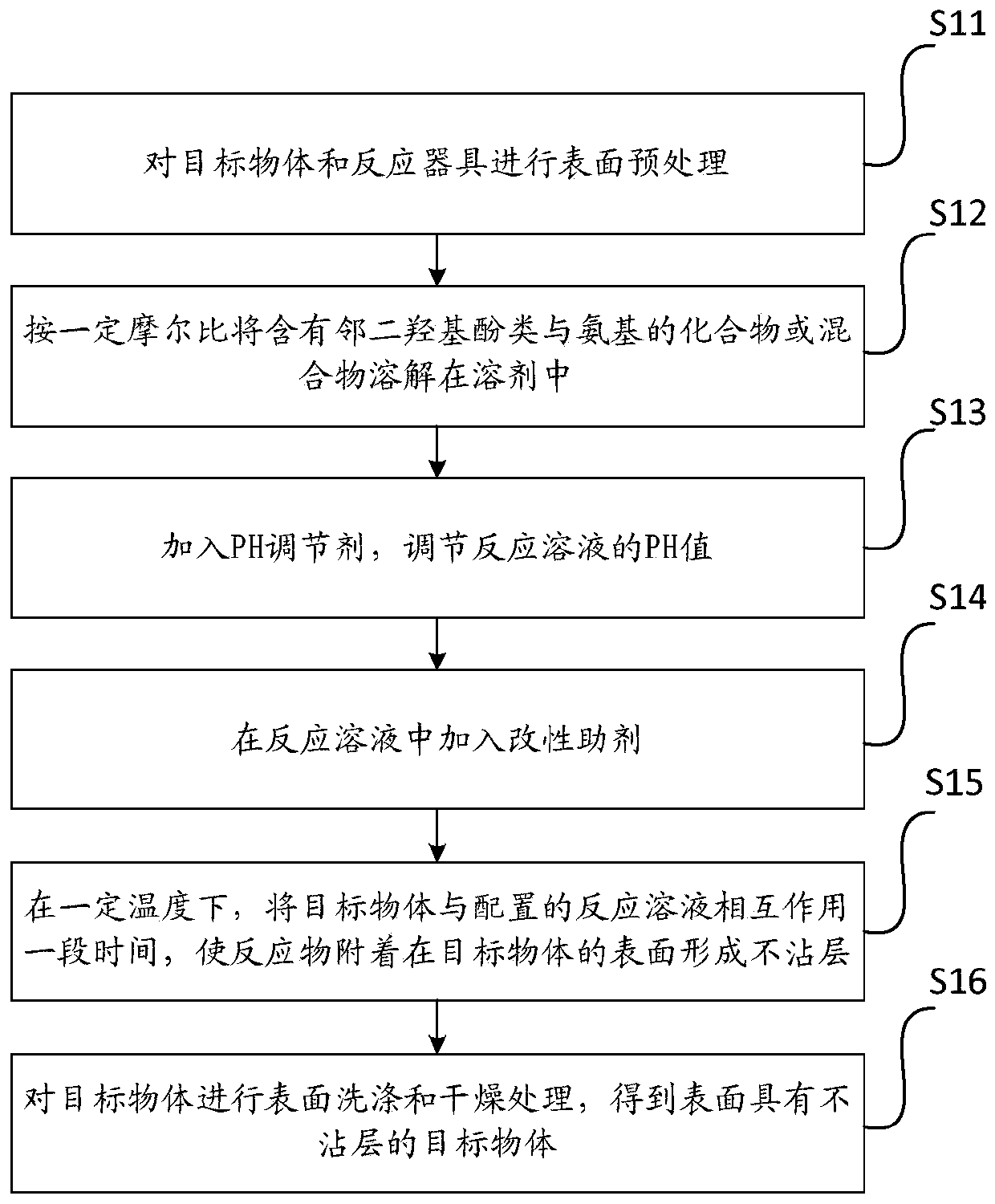

[0028] The invention discloses a method for preparing a liquid metal non-stick layer, mainly by attaching the reactant of an ortho-dihydroxyphenol compound and an amine compound in a dissolved state to the surface of an object to be in contact with liquid metal. Forms a non-stick layer on the surface. Wherein, the present invention mainly utilizes the reaction between the amino groups in ortho-dihydroxyphenols and amines, and the chemical molecular structure of ortho-dihydroxyphenols is as follows: figure 1 As shown, the chemical molecular structure of the amino group is as figure 2 shown.

[0029] The non-stick layer in the present invention is produced by the reaction of o-dihydroxyphenols and amino groups, has stable properties and irreversible reactions, and can maintain its layer structure for a long time. And the utensil prepared by this method has a non-stick layer attached to its surface, which can obviously reduce the adhesion residue of liquid metal on the utensil...

Embodiment 1

[0055] Embodiment 1. The polycarbonate (PC) ink cartridge that does not adhere to liquid metal

[0056] The polycarbonate (PC) ink cartridge that does not adhere to liquid metal comprises ink cartridge body and ink cartridge surface functional coating, and its preparation method is as follows:

[0057] A. Dissolve 5mM catechol and 5mM tetraethylenepentamine in deionized water;

[0058] B. Utilize Tris and hydrochloric acid to adjust the pH value of the above solution to about 8.6;

[0059] C. Wash the PC cartridge ultrasonically with ethanol and deionized water, and then dry it in an oven at 50°C;

[0060] D. Soak the cleaned ink cartridge in the modification solution prepared in steps a and b, react at room temperature for 20 hours, take out the ink cartridge, rinse repeatedly with deionized water, and dry naturally.

[0061] After modification, the functional coating after the reaction of catechol and tetraethylenepentamine was successfully attached to the inner and outer ...

Embodiment 2

[0062] Embodiment 2. The glass beaker that does not adhere to liquid metal

[0063] A glass beaker that does not adhere to liquid metal includes a beaker body and a functional coating on the surface of the beaker, and its preparation method is as follows:

[0064] A. Dissolve 2mM pyrogallol and 5mM triethylenetetramine in deionized water;

[0065] B. Utilize Tris and hydrochloric acid to adjust the pH value of the above solution to about 8.6;

[0066] C. Rinse the glass beaker repeatedly with ethanol and deionized water, and then dry it with hot air;

[0067] D. Use a cleaned glass beaker to store the modified solution prepared in steps a and b, react in a shaker at room temperature for 16 hours, pour out the solution in the beaker, rinse repeatedly with deionized water, and dry naturally.

[0068] After modification, the glass surface successfully adhered to the functional coating after the reaction of pyrogallol and triethylenetetramine, and various liquid metals did not a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com