Low-temperature-impact-resistant epoxy adhesive composition and preparation method thereof

A technology of epoxy adhesive and composition, applied in the direction of adhesive, epoxy resin, adhesive type, etc., can solve the problems of brittle cracking, poor toughness, brittleness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

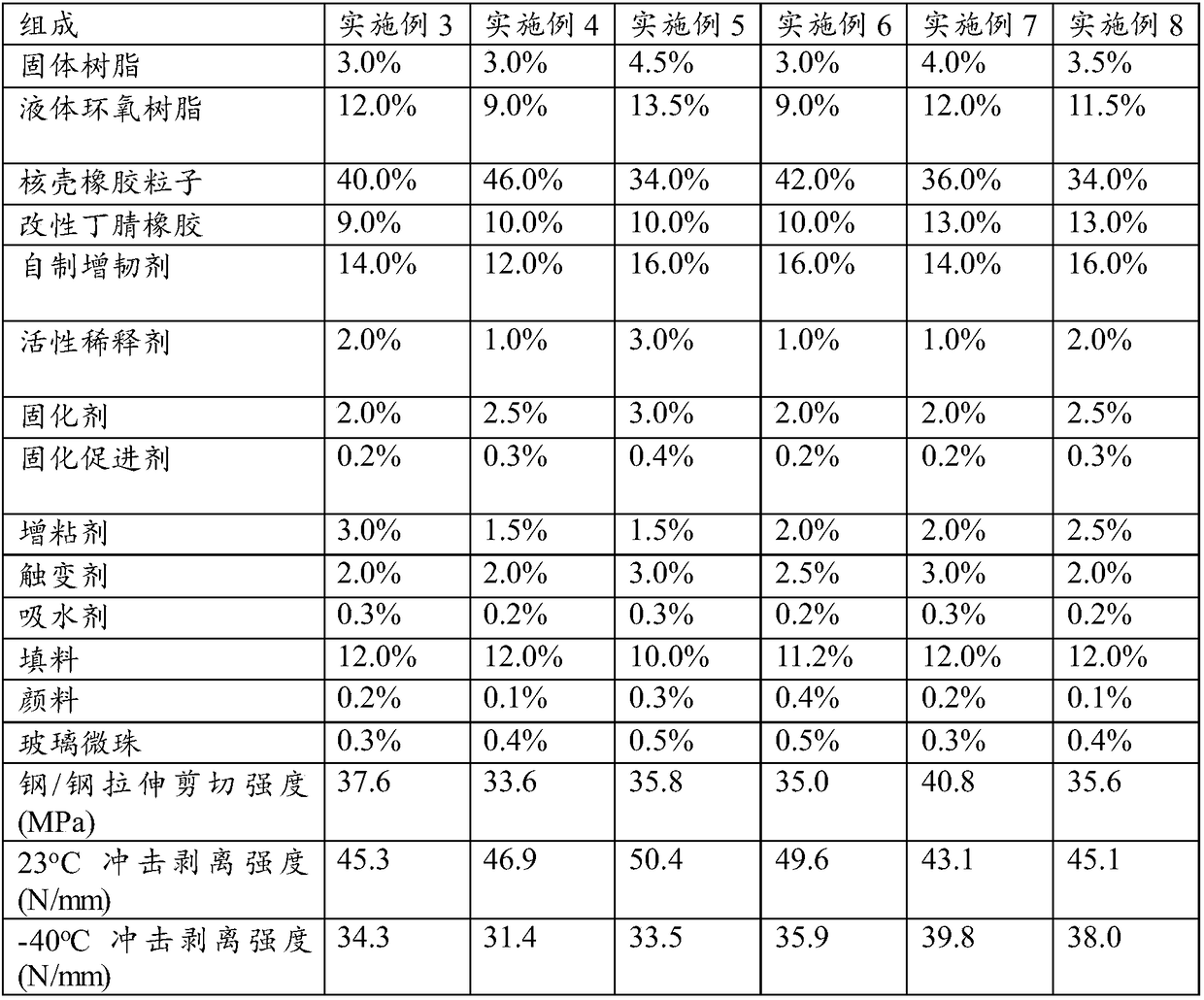

Examples

preparation example Construction

[0079] The present invention also provides a method for preparing the epoxy adhesive composition, which includes the following steps:

[0080] A) The epoxy resin is mixed and heated and melted to obtain an epoxy resin mixture;

[0081] B) Add bifunctional epoxy diluent, toughening agent, inorganic filler, dewatering agent, thixotropic agent, heat-activated latent curing agent and curing accelerator to the epoxy resin mixture, mix and stir, vacuum After deaeration, an epoxy adhesive composition is obtained.

[0082] In the present invention, the epoxy resin is first mixed and then heated and melted to obtain an epoxy resin mixture.

[0083] Specifically, the liquid epoxy resin is heated to 95-105°C, the solid epoxy resin is added, and the mixture is stirred until the solid epoxy resin melts to obtain an epoxy resin mixture;

[0084] Then, add bifunctional epoxy diluent, toughening agent, inorganic filler, dewatering agent, thixotropic agent, heat-activated latent curing agent and curing...

Embodiment 1

[0090] Example 1 Preparation of Toughening Agent A

[0091] Add 100 parts of polyether polyol (DL-2000D) with a molecular weight of 2000D to the reactor, dehydrate at 105°C for 30 minutes, then add 0.6 part of trimethylolpropane and 0.1 part of organotin catalyst, mix well, and add under nitrogen protection 26.5 parts of MDI, controlled temperature to 85-90°C, reacted for 2.0 hours under these conditions to obtain a prepolymer, and the mass percentage of -NCO group of the prepolymer was detected to be 3.3%. According to the molar ratio of the ketoxime group to the -NCO group of 1.1:1, 10.1 parts of butanone oxime was added, and the capping reaction was performed at 85-90°C for 1.5 hours. The content of the -NCO group in the product was detected to be zero, and the increase was obtained. Toughener A.

[0092] The number average molecular weight of the toughening agent A was 4,500, the weight average molecular weight was 11,000, and the dispersion index was 2.4.

Embodiment 2

[0093] Example 2 Preparation of Toughening Agent B

[0094] Add 200 parts of polyether polyol (DL 4000D) with molecular weight of 4000D to the reactor, dehydrate at 105°C for 30 minutes, then add 1.0 part of trimethylolpropane and 0.2 part of organotin catalyst to mix uniformly, add MDI28 under nitrogen protection The temperature is adjusted to 85-90°C, and the reaction is carried out for 2.5 hours under this condition to obtain a prepolymer. The content of -NCO group of the prepolymer is 1.9%. According to the molar ratio of the ketoxime group to the -NCO group of 1.1:1, 13 parts of cyclohexanone oxime were added, and the end-capping reaction was performed at 85-90°C for 1.5 hours. The content of the -NCO group in the product was detected as zero. Toughening agent B.

[0095] The number average molecular weight of the toughening agent B was determined to be 8,600, the weight average molecular weight was 22,000, and the dispersion index was 2.6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com