Antibacterial and breathable home textile fabric and making method thereof

A fabric and home textile technology, applied in the field of home textile fabrics, can solve the problems of low ventilation efficiency, difficult cost, cytotoxicity, etc., and achieve the effect of enhancing antibacterial effect, avoiding direct contact and excellent antibacterial performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

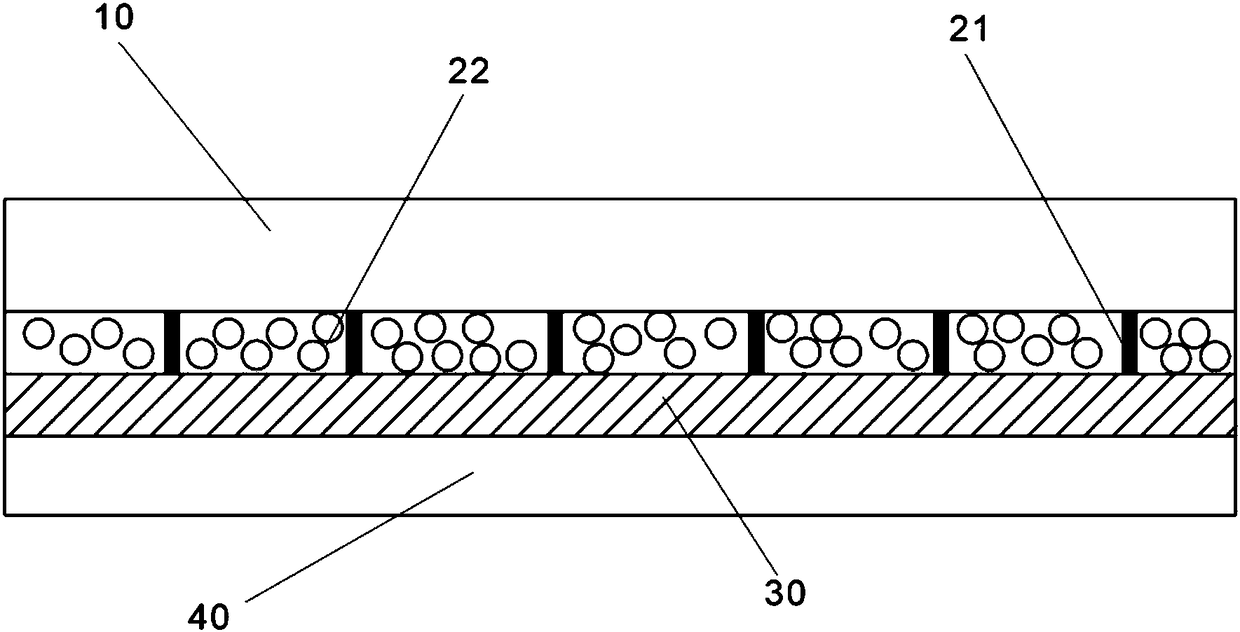

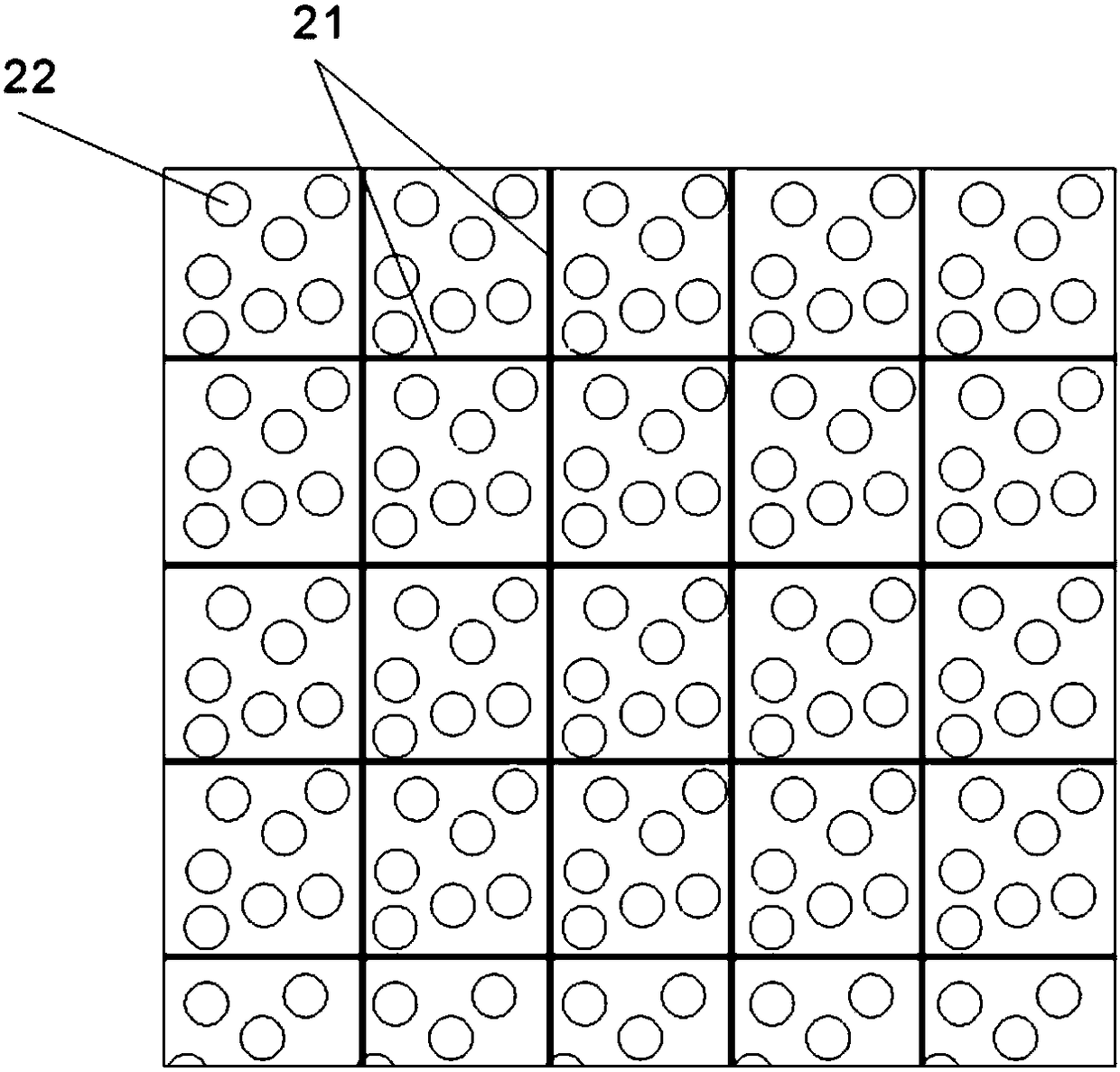

Image

Examples

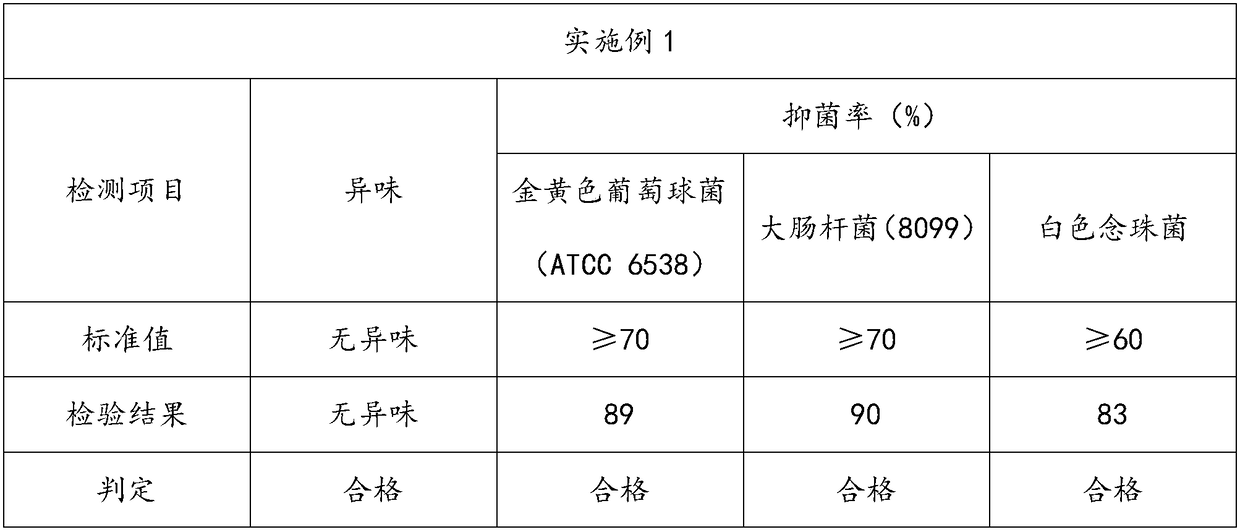

Embodiment 1

[0047] 1. Preparation of antibacterial polyester fiber

[0048] Polycondensation reaction of normal pressure polyester esterified product and polymer antibacterial agent to obtain antibacterial polyester masterbatch;

[0049] The obtained antibacterial polyester masterbatch and high-viscosity polyester chips are melt-blended and granulated, and the mass fraction of the antibacterial polyester masterbatch is 26%; the obtained blend is dried and pre-crystallized under vacuum at 76°C for 12h , and then crystallized under vacuum at 118°C for 12 hours, and then prepared antibacterial polyester fibers by melt spinning;

[0050] 2. Preparation of nano-silver antibacterial particles

[0051] Immerse nylon filaments in low-concentration nano-silver antibacterial solution No. 1, soak at 48°C for 1 hour, then dry at 80°C for 20 minutes, then immerse nylon filaments in high-concentration nano-silver antibacterial solution No. 2, and dry at 74°C Soak under water for 1.6 hours, then dry a...

Embodiment 2

[0059] 1. Preparation of antibacterial polyester fiber

[0060] Polycondensation reaction of normal pressure polyester esterified product and polymer antibacterial agent to obtain antibacterial polyester masterbatch;

[0061] The obtained antibacterial polyester masterbatch and high-viscosity polyester chips are melt-blended and granulated, and the mass fraction of the antibacterial polyester masterbatch is 35%; the obtained blend is dried and pre-crystallized under vacuum at 78°C for 12h , and then crystallized under vacuum at 120°C for 12 hours, and then prepared antibacterial polyester fiber by melt spinning;

[0062] 2. Preparation of nano-silver antibacterial particles

[0063] Immerse nylon filaments in low-concentration nano-silver antibacterial solution No. 1, soak at 48°C for 0.9h, then dry at 78°C for 20min, then immerse nylon filaments in high-concentration nano-silver antibacterial solution No. 2, and dry at 74°C. Soak at ℃ for 1.5h, then dry at 83℃ for 20min; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com