Niobium-copper alloy material and preparation method thereof

A copper alloy and formula technology, applied in medical science, prosthesis, etc., can solve the problems of metal ion dissolution, complicated surgical operation, unfavorable bone healing, etc., and achieve strong antibacterial properties, good corrosion resistance, and excellent biocompatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

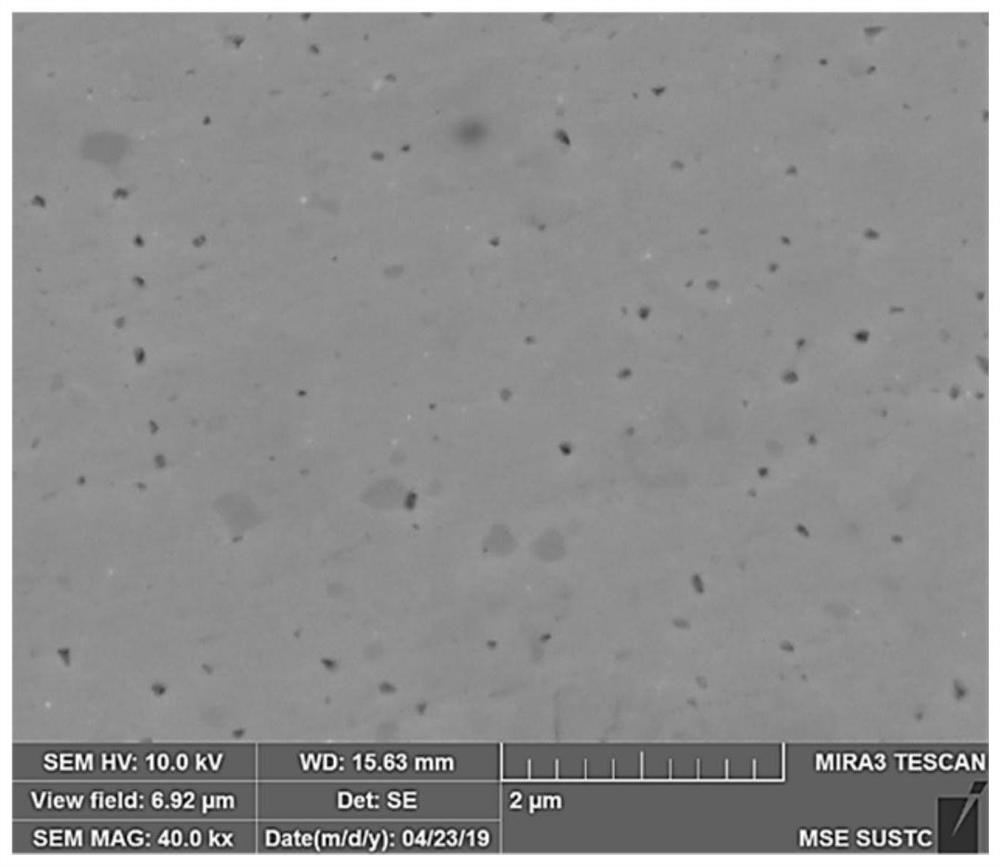

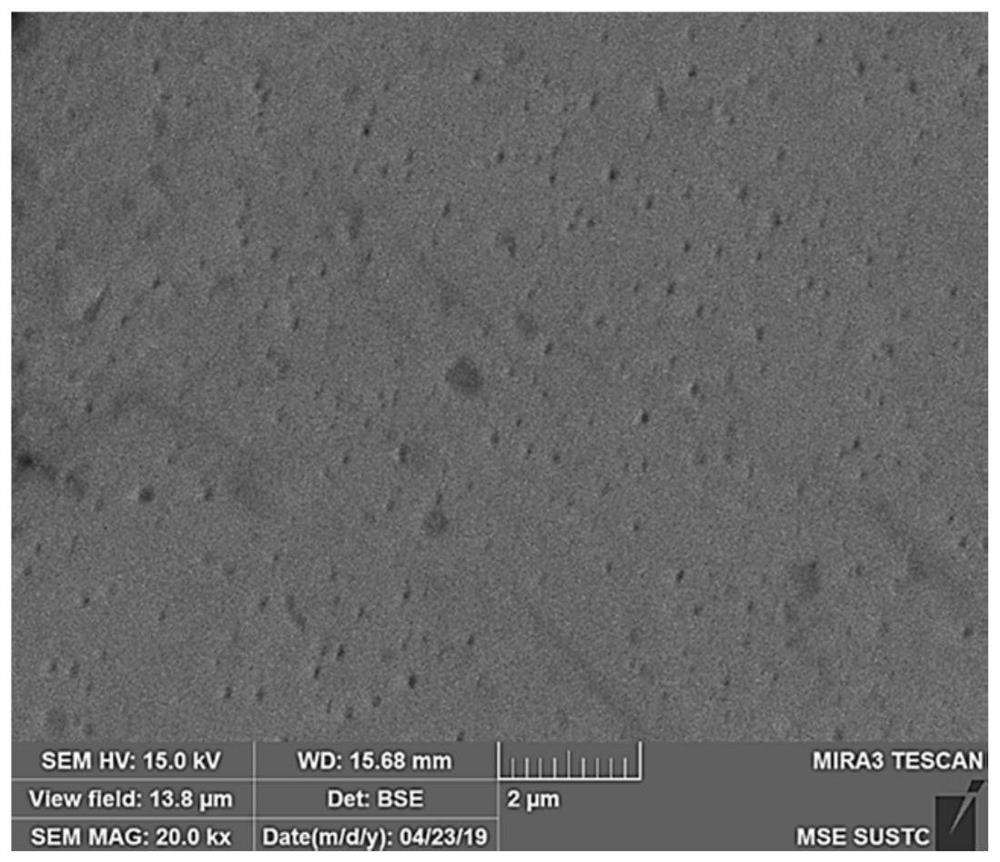

Image

Examples

Embodiment 1

[0061] This embodiment provides a niobium-copper alloy material. The niobium-copper alloy material includes: 98% niobium and 2% copper by mass percentage.

[0062] Prepared as follows:

[0063] (1) Mix the raw materials according to the formula, and perform high-energy ball milling to obtain intermediate materials;

[0064] (2) carrying out discharge plasma sintering to the intermediate material obtained in step (1), and obtaining the niobium-copper alloy material after cooling;

[0065] The high-energy ball milling in step (1) is carried out under a protective atmosphere, and the time of the high-energy ball milling is 12h;

[0066] Step (2) the discharge plasma sintering of the intermediate material is carried out by placing the intermediate material in a mold, and vacuumizing to an absolute vacuum degree of 6Pa before the discharge plasma sintering, and the discharge plasma sintering includes The first temperature rise, the first heat preservation, the second temperature ...

Embodiment 2

[0073] This embodiment provides a niobium-copper alloy material. The niobium-copper alloy material includes: 97% niobium and 3% copper by mass percentage.

[0074] Prepared as follows:

[0075] (1) Mix the raw materials according to the formula, and perform high-energy ball milling to obtain intermediate materials;

[0076] (2) carrying out discharge plasma sintering to the intermediate material obtained in step (1), and obtaining the niobium-copper alloy material after cooling;

[0077] The high-energy ball milling of step (1) is carried out under a protective atmosphere, and the time of the high-energy ball milling is 24h;

[0078] Step (2) the discharge plasma sintering of the intermediate material is carried out by placing the intermediate material in a mold, and vacuumizing to an absolute vacuum degree of 3Pa before the discharge plasma sintering, and the discharge plasma sintering includes The first temperature rise, the first heat preservation, the second temperature ...

Embodiment 3

[0085] This embodiment provides a niobium-copper alloy material. The niobium-copper alloy material includes: 99.5% niobium and 0.5% copper by mass percentage.

[0086] Prepared as follows:

[0087] (1) Mix the raw materials according to the formula, and perform high-energy ball milling to obtain intermediate materials;

[0088] (2) carrying out discharge plasma sintering to the intermediate material obtained in step (1), and obtaining the niobium-copper alloy material after cooling;

[0089] The high-energy ball milling of step (1) is carried out under a protective atmosphere, and the time of the high-energy ball milling is 6h;

[0090] Step (2) the discharge plasma sintering of the intermediate material is carried out by placing the intermediate material in a mold, and vacuumizing to an absolute vacuum degree of 1 Pa before the discharge plasma sintering, and the discharge plasma sintering includes The first temperature rise, the first heat preservation, the second temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com