Wood-based composite material releasing negative oxygen ions and preparation method thereof

A technology of negative oxygen ions and composite materials, used in wood treatment, wood impregnation, wood impregnation, etc., can solve problems such as the reduction of negative oxygen ions, and achieve the effects of easy control of conditions, promotion of metabolism, and enhancement of body disease resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

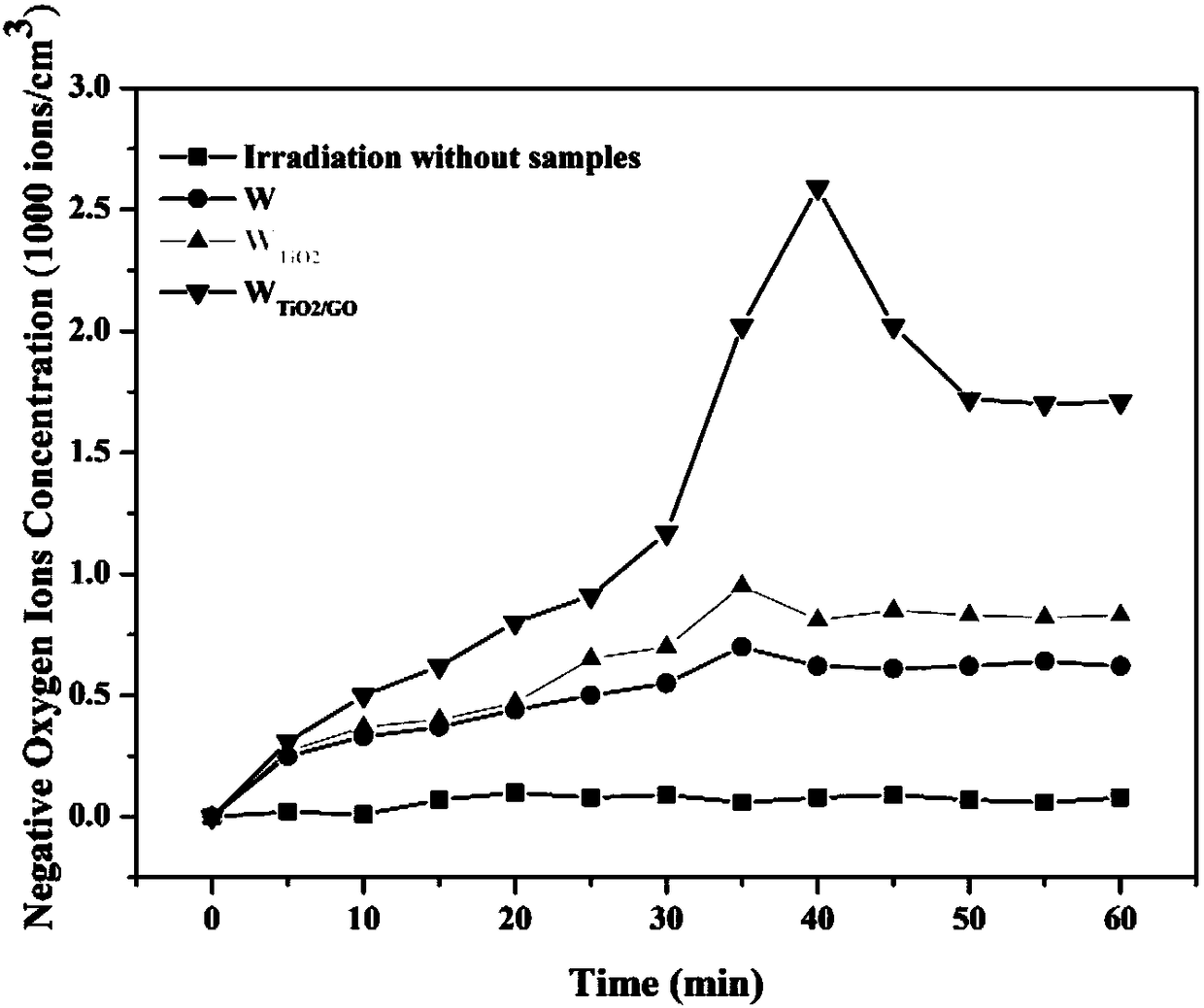

[0019] According to this embodiment, a wood-based composite material that releases negative oxygen ions under visible light irradiation is irradiated with visible light with a wavelength of 380nm to 780nm for 60 to 300 minutes, and the number of negative oxygen ions released is greater than 2500 / cm 2 ;

[0020] The described wood-based composite material that releases negative oxygen ions under visible light irradiation is that untreated wood is pressure-impregnated into a functional wood modifier of graphene oxide, nano-silica, and nano-titanium dioxide, and finally Wash and dry to get.

[0021] The beneficial effects of this embodiment are: 1. The forbidden band width of nano-titanium dioxide is relatively wide, and it is easy to generate photogenerated electrons and hole recombination under visible light irradiation, so that the negative oxygen ions produced are reduced. In order to suppress the photogenerated electrons and hole recombination and improve Charge mobility, t...

Embodiment 2

[0026] The difference between this embodiment and specific embodiment one is: the described functional wood modifier is prepared according to the following steps: first design two pre-experiments, a. take GO (0.25wt%)+SiO 2 (30wt%) mixed, stirred evenly with an electromagnetic stirrer, pressurized and impregnated to treat the substrate, and tested the physical properties such as bending resistance, hardness, water absorption, thermal stability, and adsorption capacity of the composite material obtained, so that according to the comprehensive performance Performance determines the better ratio; b. Take GO (0.25wt%)+TiO 2 (0.8wt%) mixed, stirred evenly with an electromagnetic stirrer, pressurized and impregnated the substrate, tested the performances such as negative oxygen ion release, harmful gas absorption, and antibacterial properties of the composite material obtained, and determined the optimal ratio. SiO 2 (30wt%)+TiO 2 (0.8wt%)+GO (0.25wt%) were mixed, and mixed evenly...

Embodiment 3

[0029] The difference between this embodiment and one of the specific embodiments one or two is that the wood loaded with functional wood modifier is prepared according to the following steps: the base material is fixed on a pulse impregnation machine, and the modifier is pneumatically A diaphragm pump provides pulsating pressure to be injected from one side of the substrate. Select the growth direction of the wood as the direction of pulse inclination, the trunk and the low molecular modifier will flow out from the other side of the wood, and after 30 minutes, the sap in the xylem is gradually replaced by the latest functional wood modifier. After impregnation, the obtained wood was dried in the air for 48 hours, and then transferred to an oven for drying. The drying temperature was 90° C., the drying time was about 200 hours, and the wood pressure was 0.2 MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com