Porosity change controllable porous ceramic material and preparation method thereof

A technology of porous ceramics and porosity, which is applied in the field of porous ceramic materials with controllable porosity changes and its preparation. It can solve the problems of non-porous materials, limited application range, and difficulty in mass production, and achieves high repeatability. The effect of broadening the application range and stabilizing the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

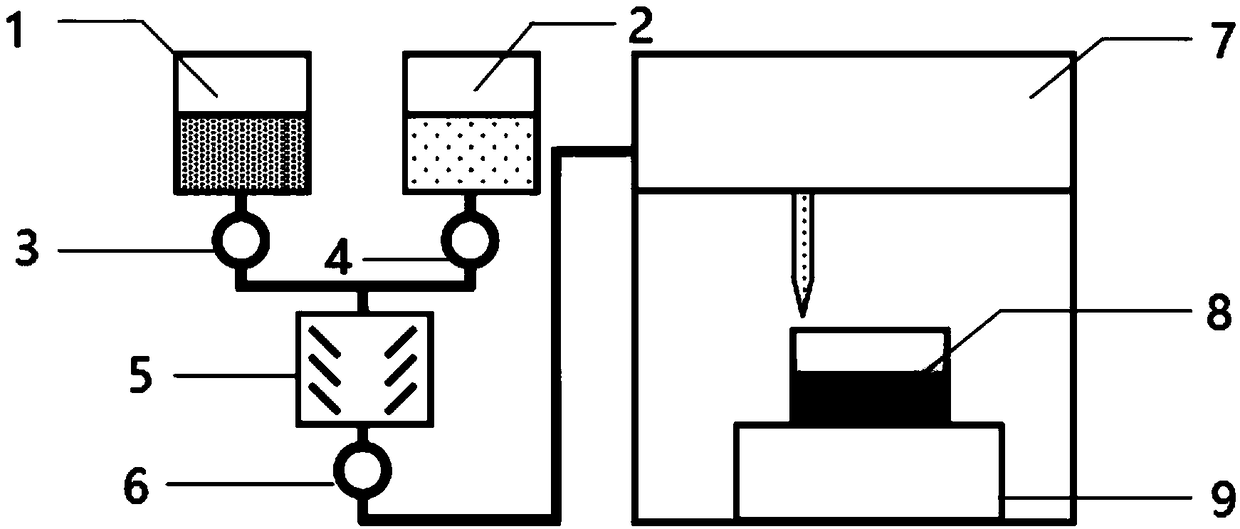

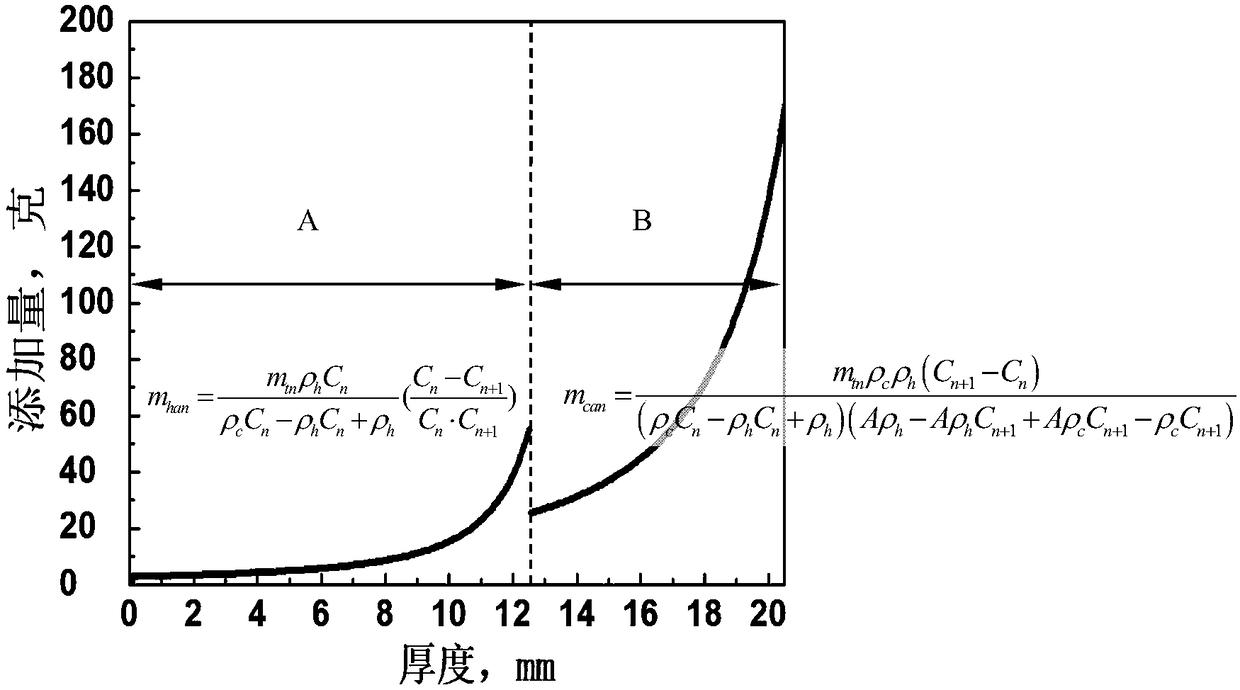

[0050] The invention provides a method for preparing a porous ceramic material with controllable porosity change, comprising the following steps:

[0051] Step S1: According to the variation of the porosity of the porous ceramic material with the thickness, the variation of the solid phase content of the ceramic slurry for preparing the porous ceramic material with the thickness is determined.

[0052] Under the premise that the material composition and preparation process are constant, there is a one-to-one correspondence between the solid phase content of the ceramic slurry and the porosity of the porous ceramic material. The corresponding relationship between porosity and solid phase content can be determined through experiments. By controlling the change law of the solid phase content in the ceramic slurry with the thickness, the porosity of the porous ceramic material obtained after sintering also changes regularly with the thickness. That is, by controlling the change r...

Embodiment 1

[0103] This embodiment provides a method for preparing a porous ceramic material with controllable porosity change, which includes the following steps in sequence:

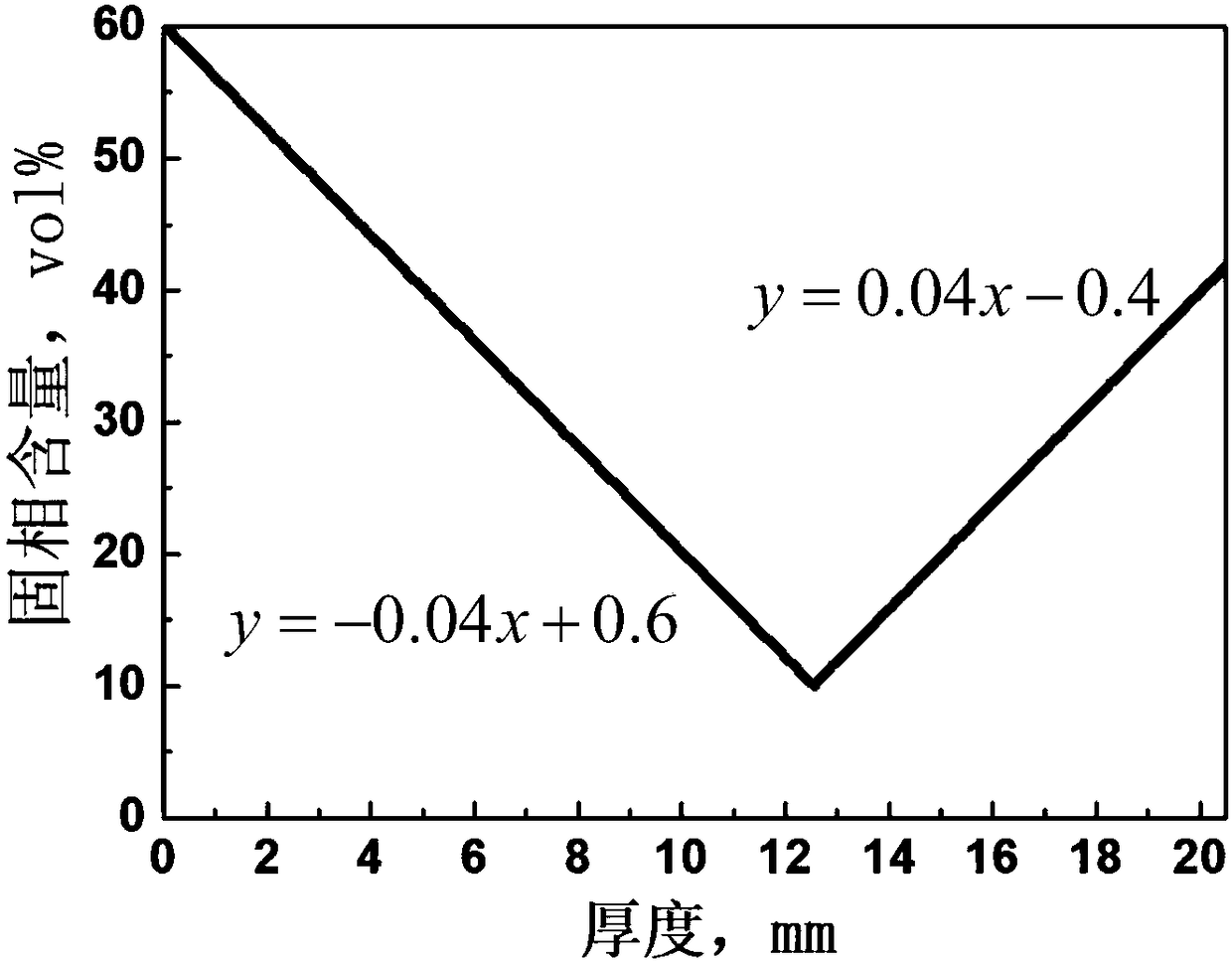

[0104] Step S1: The porosity of the porous ceramic material increases linearly from 34vol% to 83vol% in the thickness direction, and the change size in the thickness direction is 12.20mm, and then the porosity decreases linearly from 83vol% to 52vol%, and the change size in the thickness direction is 7.80mm. The corresponding relationship between porosity and solid phase content is determined through experiments, and the variation law of solid phase content in ceramic slurry with thickness is determined by considering factors such as sintering shrinkage rate and machining allowance, as follows: figure 2 shown. The solid phase content decreases linearly from 60vol% to 10vol% in the thickness direction, and the decreasing change satisfies the equation y=-0.04x+0.6, 0≤x≤12.5, and then the solid phase content increas...

Embodiment 2

[0115] This embodiment provides a method for preparing a porous ceramic material with controllable porosity change, which includes the following steps in sequence:

[0116] Step S1: The porosity of the porous ceramic material increases from 38vol% to 85vol% in the thickness direction according to the parabola equation, and the change size in the thickness direction is 12.20mm, and then the porosity decreases from 85vol% to 56vol% according to the parabola equation, and the change size in the thickness direction is 7.80mm. The corresponding relationship between porosity and solid phase content was determined through experiments, and factors such as sintering shrinkage and machining allowance were comprehensively considered to determine the change law of solid phase content in ceramic slurry with thickness, as shown in Figure 7 shown. In the thickness direction, the solid phase content gradually decreases from 60vol% to 10vol%, and the decreasing change satisfies the equation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com