Thermosetting airgel modified polystyrene board and its preparation method and building wall

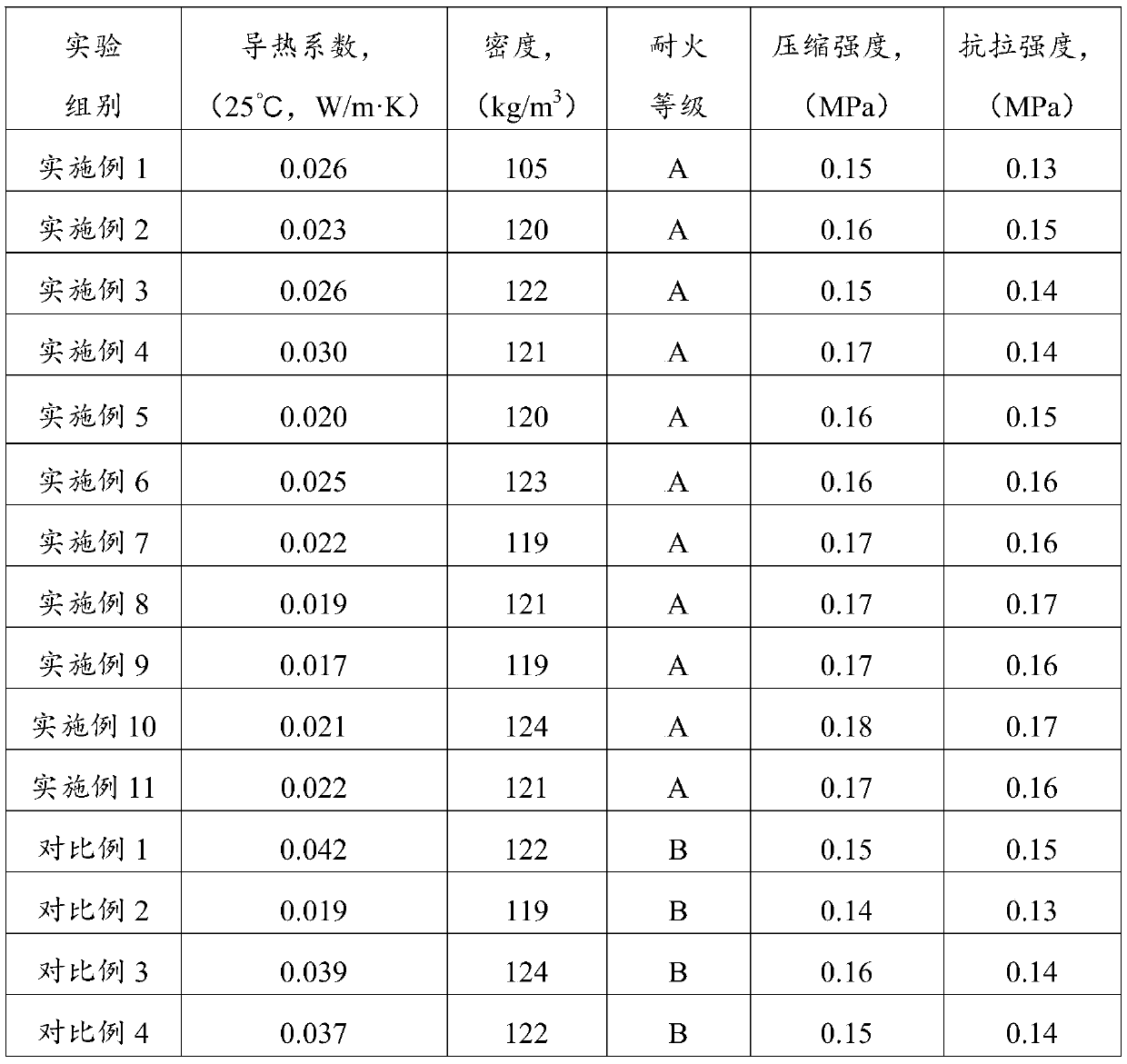

An airgel and thermosetting technology, which is applied in the field of polystyrene board building materials, can solve the problems that the flame retardancy can only reach B level, the fire spreads quickly, and the flame retardancy declines, and achieves excellent fire resistance, light weight, and fire resistance. The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0051] As a preferred embodiment of the present invention, the thermosetting aerogel modified polystyrene board comprises the following parts by weight of raw materials: 90-110 parts of expandable polystyrene, 45-140 parts of thermosetting resin, and 18 parts by weight. -24 parts and 40-130 parts of coating material;

[0052] Wherein, the coating material includes flame retardant and silica aerogel, and the weight ratio of flame retardant to silica aerogel is (1-6):1.

[0053] As a preferred embodiment of the present invention, the thermosetting aerogel modified polystyrene board comprises the following parts by weight of raw materials: 95-105 parts of expandable polystyrene, 50-120 parts of thermosetting resin, and 18 parts by weight. -22 parts and 45-120 parts of coating material;

[0054] Among them, the coating material includes flame retardant and silica aerogel, and the weight ratio of flame retardant to silica aerogel is (2-5):1.

[0055] By further limiting the amount of each...

Embodiment 1

[0087] The thermosetting aerogel-modified polystyrene board provided in this embodiment includes the following parts by weight of raw materials: 80 parts of expandable polystyrene, 45 parts of furfural resin, 15 parts of p-toluenesulfonic acid and coating Material 45 parts;

[0088] Among them, the coating material includes calcium carbonate and silica aerogel, the weight ratio of calcium carbonate and silica aerogel is 0.5:1, and the silica aerogel includes micron-sized silica aerogel and sub Micron-sized silica aerogel, the median particle size of micron-sized silica aerogel is 5.0μm, and the median particle size of sub-micron-sized silica aerogel is 0.5μm. The weight ratio of gel to submicron silica aerogel is 0.5:1.

[0089] The preparation method of the thermosetting aerogel modified polystyrene board includes the following steps:

[0090] (a) The expandable polystyrene is steam pre-expanded, the pressure of the steam is 0.08MPa, the time of steam is 30s, and the density is 16...

Embodiment 2

[0094] The thermosetting aerogel modified polystyrene board provided in this embodiment is made of the following raw materials in parts by weight: 100 parts of expandable polystyrene, 80 parts of phenolic resin, 20 parts of phosphoric acid and 100 parts of coating material ;

[0095] Among them, the coating material includes aluminum hydroxide and silica aerogel, the weight ratio of aluminum hydroxide and silica aerogel is 1:1, and the silica aerogel includes micron-sized silica aerogel. And submicron silica aerogels, the median size of micron silica aerogels is 10.0μm, the median size of submicron silica aerogels is 1.0μm, micron dioxide The weight ratio of silica aerogel and submicron silica aerogel is 1:1.

[0096] The preparation method of the thermosetting aerogel modified polystyrene board includes the following steps:

[0097] (a) The expandable polystyrene is pre-steamed, the pressure of the steam is 0.09MPa, the time of steam is 40s, and the density is 20kg / m 3 Of pre-expa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com