High-temperature resisting anti-cracking clutch facing and preparation technology thereof

The invention relates to a technology for a clutch face plate and a preparation process, which is applied in the field of high-temperature and crack-resistant clutch face plate and its preparation technology. Molecular contact effective area, strong adsorption capacity, and the effect of optimizing the process environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

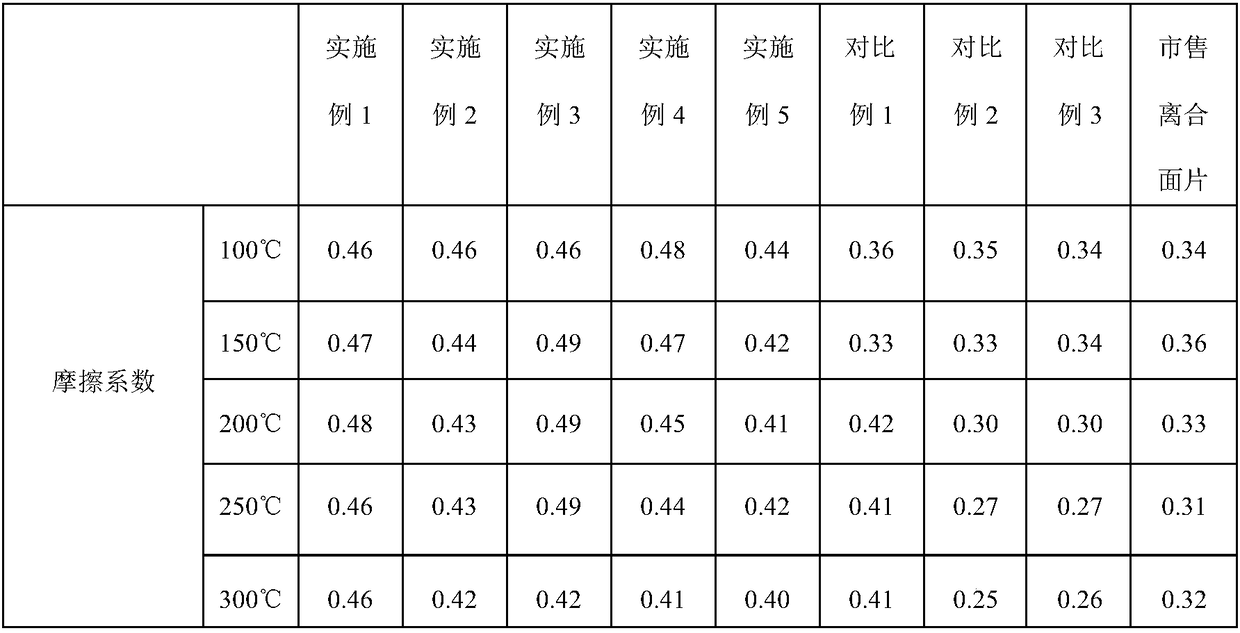

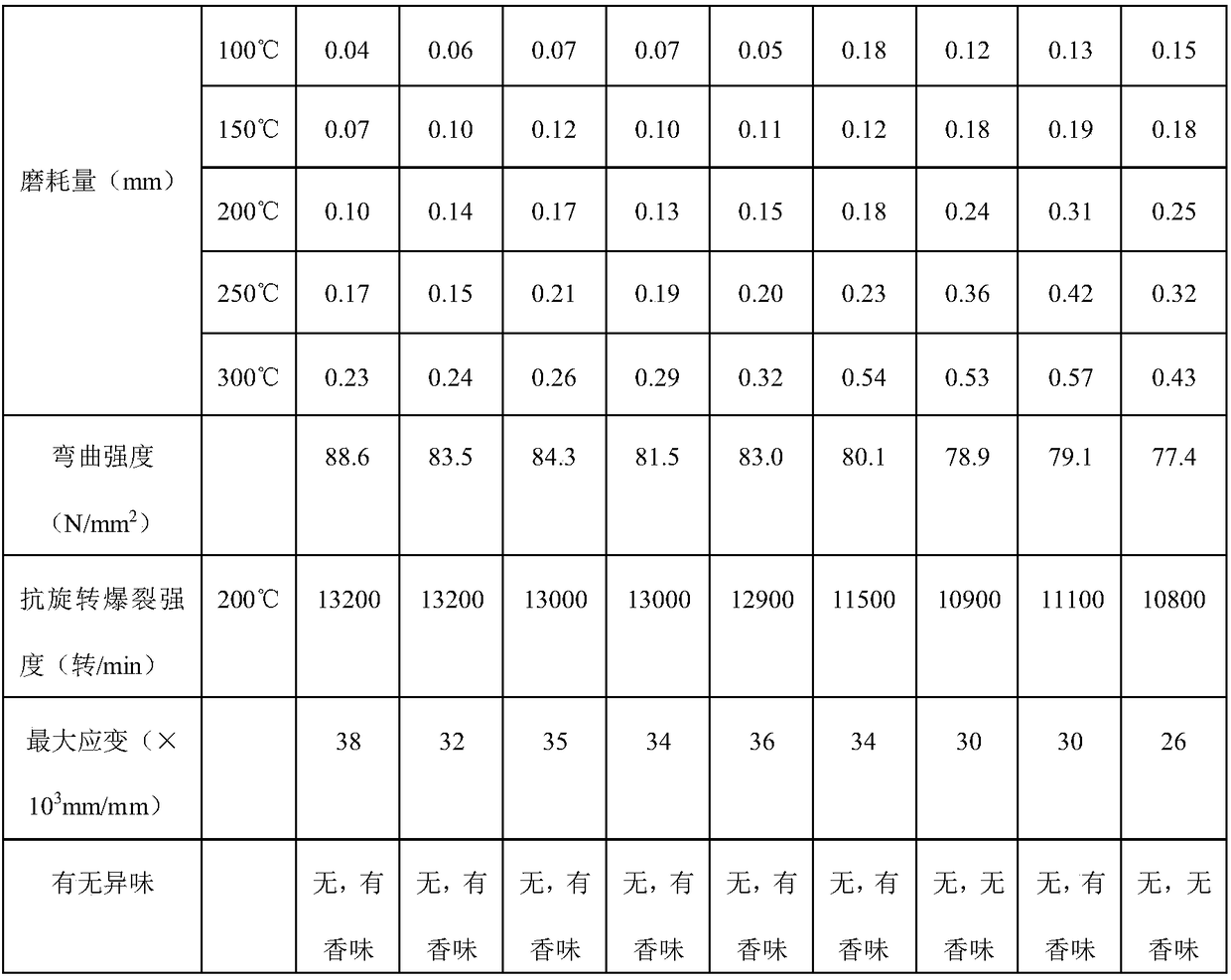

Examples

Embodiment 1

[0041] A high-temperature-resistant and anti-cracking clutch face, made of the following raw materials in parts by weight: 4 parts by weight of styrene-butadiene rubber, 0.6 parts of modified bamboo fiber, 0.6 part of ceramic fiber, and 5 parts of reinforcing material , 2 parts of single-layer graphene, 7 parts of nano-silica, 1 part of nano-titanium dioxide, 6 parts of zinc stearate, 1 part of sulfur and 18 parts of phenolic resin.

[0042] The weight ratio of the modified bamboo fiber and the ceramic fiber is 1:1.

[0043] The modified bamboo fiber is prepared from the following raw materials in parts by weight: 0.2 part of ling vanilla and 0.4 part of bamboo fiber.

[0044] The preparation technology of modified bamboo fiber is as follows:

[0045] (1): Add 0.2 parts of Herba Lingensis into ethanol with a volume fraction of 70% and stir ultrasonically at 20 kHz for 0.5 hours, then filter, recover the ethanol solution, and obtain the recovered solution for later use;

[00...

Embodiment 2

[0068] A high-temperature-resistant and anti-cracking clutch face, made of the following raw materials in parts by weight: 2 parts of styrene-butadiene rubber, 0.6 parts of modified bamboo fiber, 0.6 part of ceramic fiber, 5 parts of reinforcing material, 1 part of single-layer graphene, nano 5 parts of silicon dioxide, 1 part of nano titanium dioxide, 4 parts of zinc stearate, 1 part of sulfur and 15 parts of phenolic resin.

[0069] The weight ratio of the modified bamboo fiber and the ceramic fiber is 1:1.

[0070] The modified bamboo fiber is prepared from the following raw materials in parts by weight: 0.2 part of ling vanilla and 0.4 part of bamboo fiber.

[0071] The preparation technology of modified bamboo fiber is as follows:

[0072] (1): Add 0.2 parts of Herba Lingensis into ethanol with a volume fraction of 70% and stir ultrasonically at 20 kHz for 0.5 hours, then filter, recover the ethanol solution, and obtain the recovered solution for later use;

[0073] (2)...

Embodiment 3

[0095] A high-temperature-resistant and anti-cracking clutch face sheet, made of the following raw materials in parts by weight: 3 parts of styrene-butadiene rubber, 0.6 parts of modified bamboo fiber, 0.6 part of ceramic fiber, 7 parts of reinforcing material, 1 part of single-layer graphene, nano 5 parts of silicon dioxide, 3 parts of nano titanium dioxide, 5 parts of zinc stearate, 1 part of sulfur and 16 parts of phenolic resin.

[0096] The weight ratio of the modified bamboo fiber and the ceramic fiber is 1:1.

[0097] The modified bamboo fiber is prepared from the following raw materials in parts by weight: 0.2 part of ling vanilla and 0.4 part of bamboo fiber.

[0098] The preparation technology of modified bamboo fiber is as follows:

[0099] (1): Add 0.2 parts of Herba Lingensis into ethanol with a volume fraction of 70% and stir ultrasonically at 20 kHz for 0.5 hours, then filter, recover the ethanol solution, and obtain the recovered solution for later use;

[01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com