Heat-conductive additive material, preparation method, and application thereof

A technology for adding materials and composite materials, applied in the field of materials, can solve the problems of poor compatibility between metal oxide particles and substrates, expensive limitations of carbon nanomaterials, etc., to achieve easy promotion and process optimization, good dispersion stability, and high yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

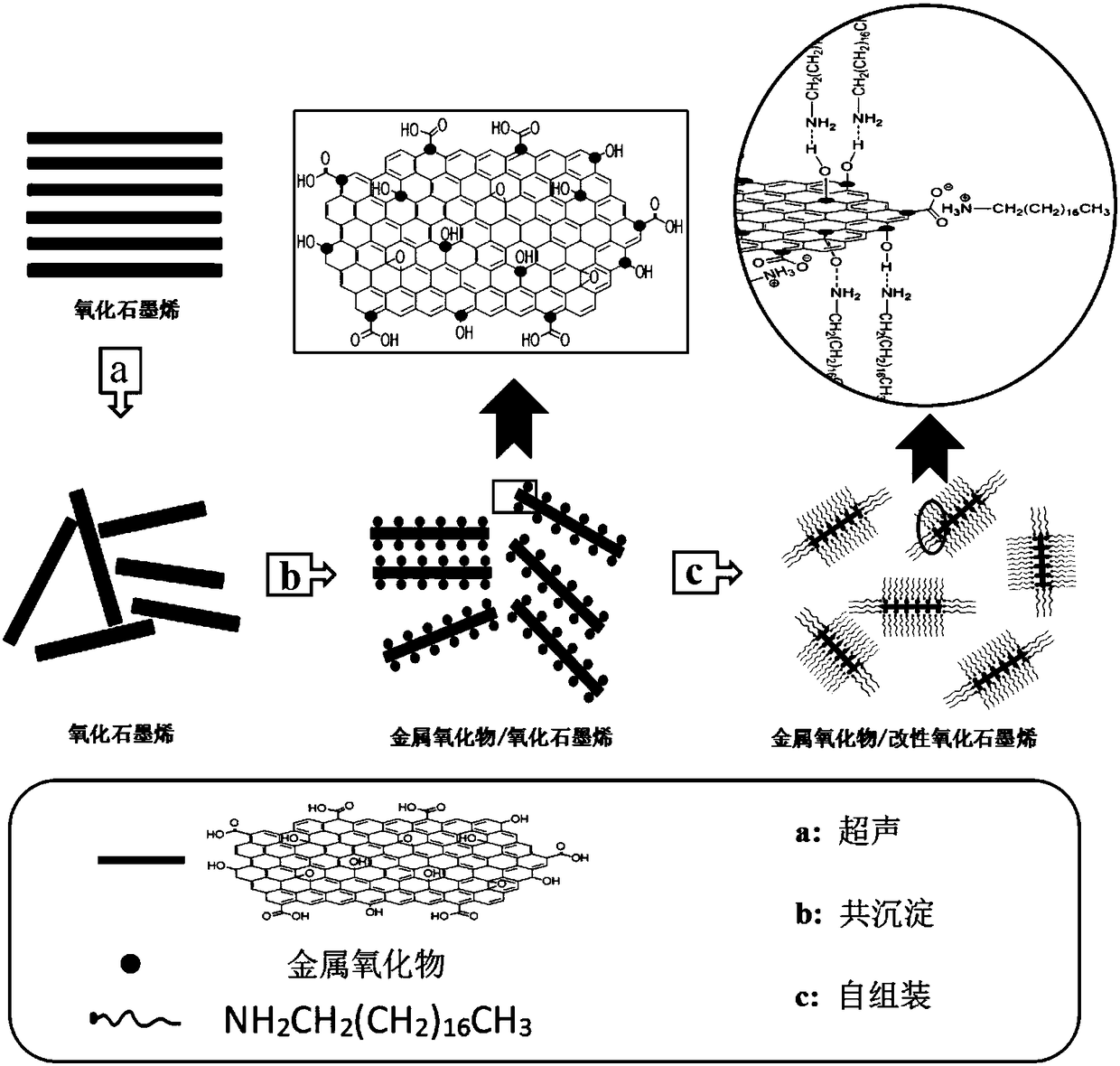

[0030] The invention provides a method for preparing a thermally conductive additive material, comprising the following steps:

[0031] A) under alkaline conditions, after the aqueous solution of graphene oxide is mixed with the aqueous solution containing metal ions, carry out co-precipitation reaction, obtain nanometer metal oxide / graphene oxide composite material;

[0032] B) Mixing and reacting the nano-metal oxide / graphene oxide composite material with alkylamine to obtain a thermally conductive additive material, the alkylamine being selected from dodecylamine, tridecylamine, tetradecylamine, hexadecylamine, Octadecylamine or Diisotridecylamine.

[0033] In the present invention, an aqueous solution of graphene oxide and an aqueous solution containing metal ions are first prepared. Wherein, the configuration method of the aqueous solution of the graphene oxide is:

[0034] The graphene oxide is mixed with deionized water and ultrasonicated to obtain a graphene oxide aq...

Embodiment 1

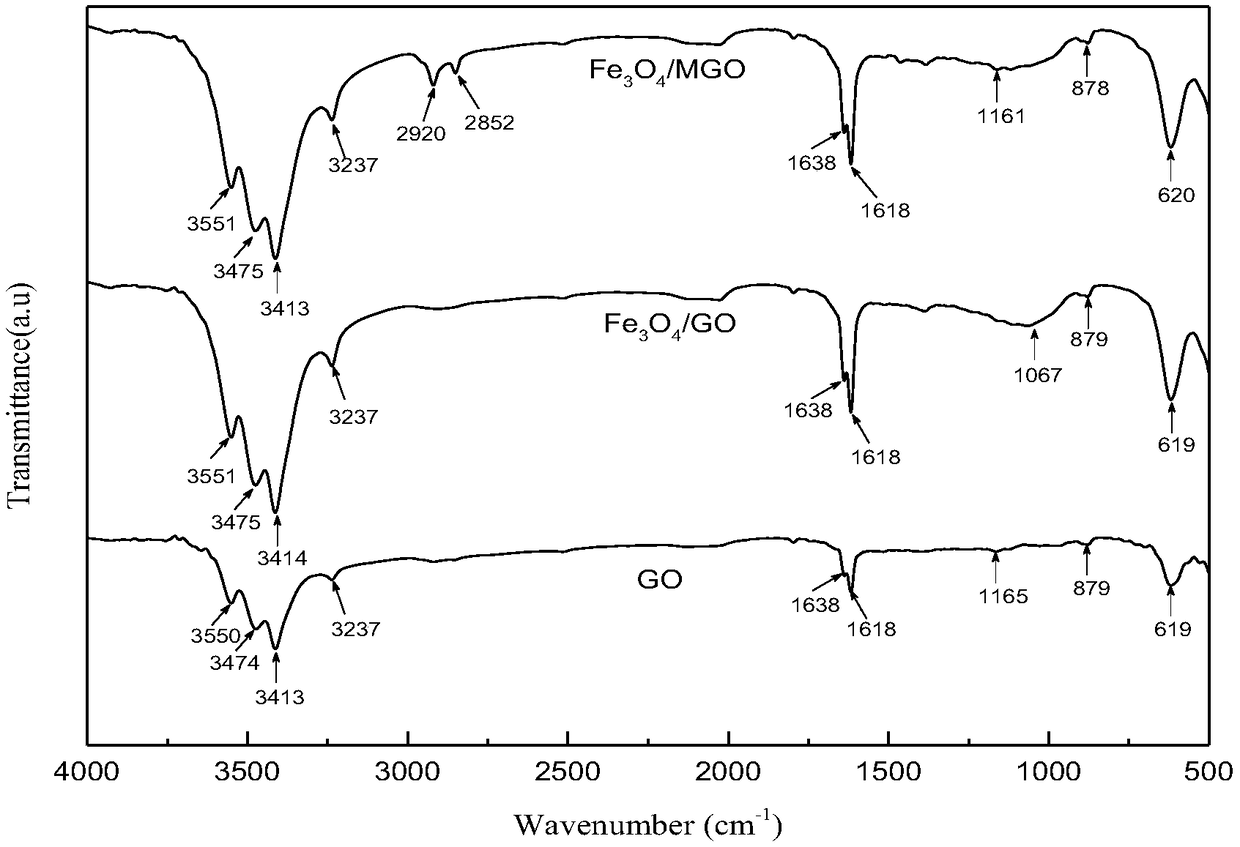

[0071] In this example, the metal oxide / modified graphene oxide composite material is first obtained by chemical co-precipitation of metal ions and graphene oxide to obtain nanometer metal oxide / graphene oxide, and then the nanometer metal oxide / graphene oxide and alkylamine Nanoscale metal oxide / modified graphene oxide composites were prepared by self-assembly. Its metal metal ions use Fe 3+ , Fe 2+ , Alkylamine selects 18 amines for use. Specific steps are as follows:

[0072] Take 800 mg of graphene oxide and add it into 400 mL of deionized water, and sonicate for 1 hour to obtain a 2 mg / mL graphene oxide solution. Add 160mL of ammonia water to the graphene oxide solution, and slowly add dissolved (0.5g FeCl 3 ·6H 2 O, 1.0g FeCl 2 4H 2 O) 60 mL of aqueous solution, continue to sonicate for 0.5 h. Transfer to an oil bath at 80°C and stir for 5 hours, cool down to room temperature, and wash several times with 150 mL deionized water and 50 mL DMF respectively to obtain...

Embodiment 2

[0080] The preparation method of this embodiment is the same as that of Example 1, except that the metal ions come from copper chloride and aluminum chloride, and the consumption is respectively 0.1g and 0.6g, as shown in Example 2. The metal ions used in the preparation process of the novel heat-conducting material disclosed in the present invention are not limited to a certain element, and can be mixed in various types, and are not limited to a certain fixed weight ratio. The types of metal ions in the new heat-conducting material have a variable mass ratio.

[0081] The result of the composite material prepared in Example 2 is similar to that of Example 1, that is, it has good stable dispersion in liquid paraffin and good thermal conductivity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com