An energy-saving and environment-friendly single-tube vertical carbonization furnace

An energy-saving and environmentally friendly carbonization furnace technology, which is applied in fixed carbonization furnaces, coke ovens, and special forms of carbonization, can solve problems such as low work efficiency and large floor space, and achieve increased work efficiency, energy saving, and reduction of all equipment. The effect of occupying area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

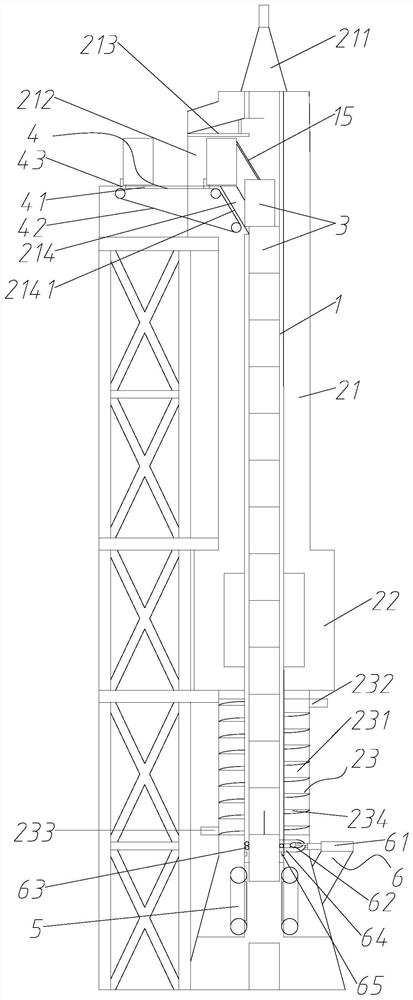

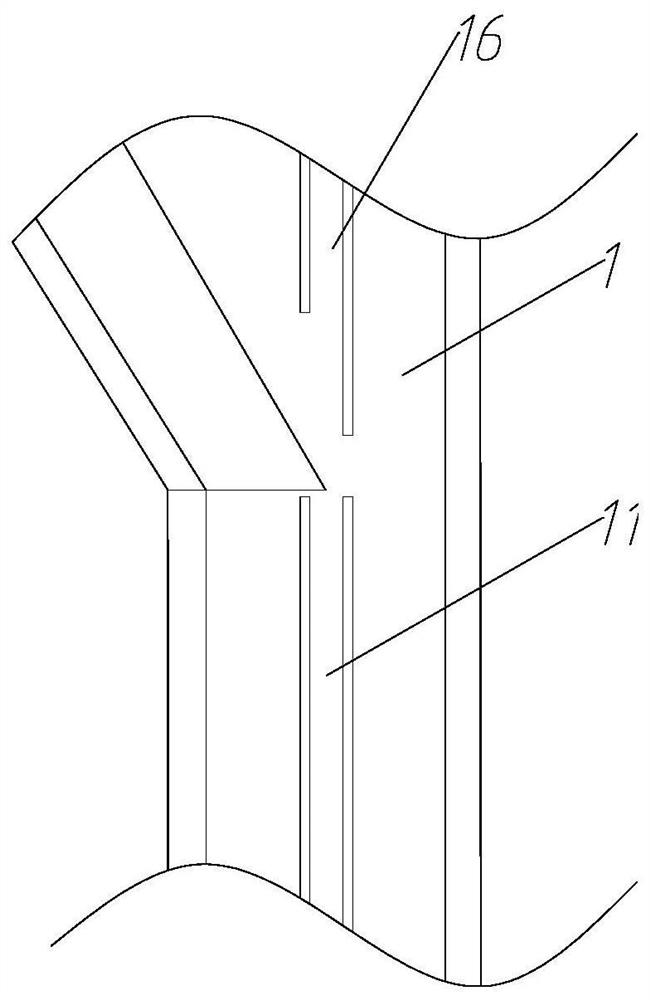

[0043] Embodiment 1: An energy-saving and environment-friendly single-tube vertical carbonization furnace, including a carbonization pipeline 1, the outside of the carbonization pipeline 1 is provided with a preheating furnace body 21, a heating furnace body 22 and a cooling furnace body 23 in sequence from top to bottom, and the carbonization pipeline 1 The inner slide is provided with a material crucible 3,

[0044] Both the preheating furnace body 21 and the heating furnace body 22 are made of insulating materials, the heating furnace body 22 is provided with an electric heating device, the cooling furnace body 23 is provided with an annular cavity 231, and the bottom and top of the annular cavity 231 are respectively provided with Water outlet 232 and water inlet 233.

[0045] In this embodiment, a vertical structure is adopted. During work, the carbon powder material is put into the material holding crucible 3 to be heated and carbonized, so that there is no relative move...

Embodiment 2

[0047] Embodiment 2: The top of the preheating furnace body 21 is provided with a flue gas collection cover 211, and the flue gas collection cover 211 is connected with a dust removal and desulfurization device.

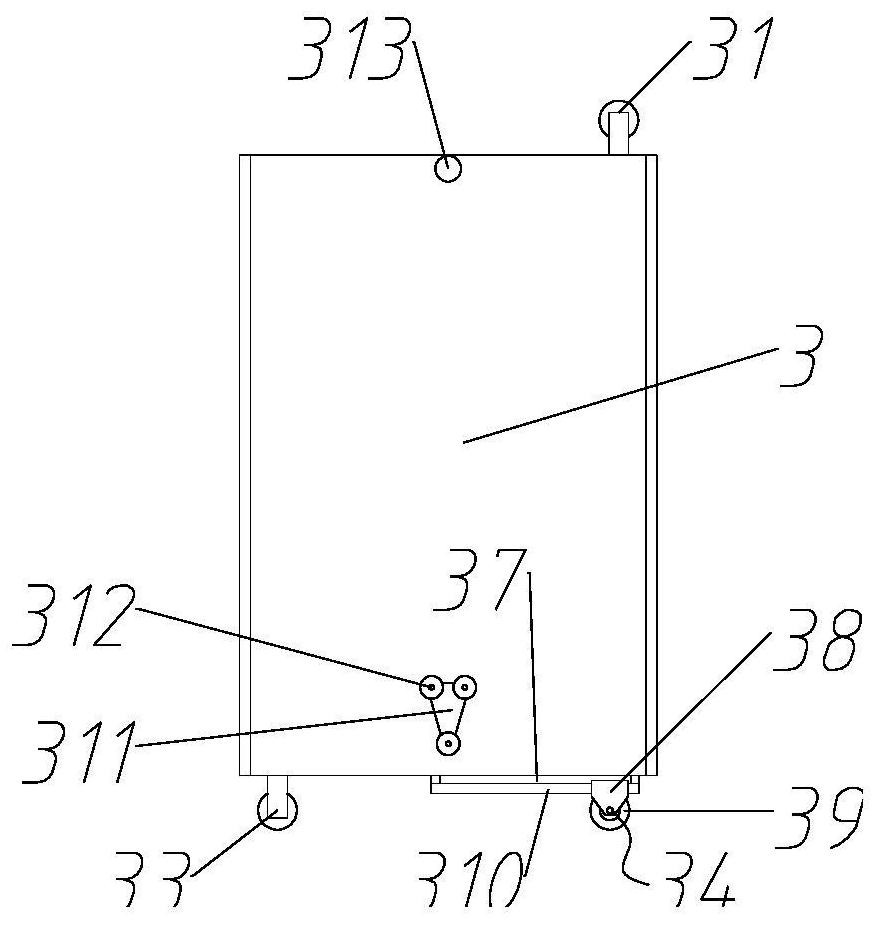

[0048] A feed port 212 is provided under the flue gas collection cover 211, and the crucible 3 enters the carbonization pipeline 1 through the feed port 212, and a feed platform 4 is provided outside the preheating furnace body 21, and the feed platform 4 and the feed port 212 are located At the same height, a pulley 31 or a slider is provided on one side of the top of the crucible 3 for holding materials, and a slide rail 213 is provided above the feed opening 212, and the pulley 31 or the slider is slidably arranged on the slide rail 1 213.

[0049] In this embodiment, the flue gas collection hood 211 arranged on the top of the preheating furnace body 21 can recover the flue gas and hot gas generated in the vertical carbonization furnace, preventing the flue gas and...

Embodiment 3

[0050] Embodiment 3: There are several material crucibles 3 slidingly arranged inside the carbonization pipeline 1, a support frame 2 is arranged under the carbonization pipeline 1, and a supporting mechanism 5 for making the material crucibles 3 fall at a constant speed is arranged on the support frame 2,

[0051] The preheating furnace body 21 is provided with a feeding guideway 214. The section of the feeding guideway 214 on the horizontal plane is a semicircle and the radius is equal to the radius of the carbonization pipeline 1. Connected along the edge, the arc edge above the feed guide 214 is connected with the feed platform 4,

[0052] When the material-containing crucible 3 slides from the feeding platform 4 into the feeding guideway 214, the pulley one 31 or the slider is separated from the slide rail one 213.

[0053] In this embodiment, a plurality of material-filling crucibles 3 are arranged in sequence along the vertical direction in the carbonization pipeline 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com