Modified A356 aluminum alloy and multi-time aging heat treatment method thereof

An aluminum alloy and modification technology, which is applied in the field of modified A356 aluminum alloy and its multiple aging heat treatment, can solve the problems of limited performance indicators, difficulty in meeting the increasingly high requirements of material performance, etc., and achieves improved strength and production cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

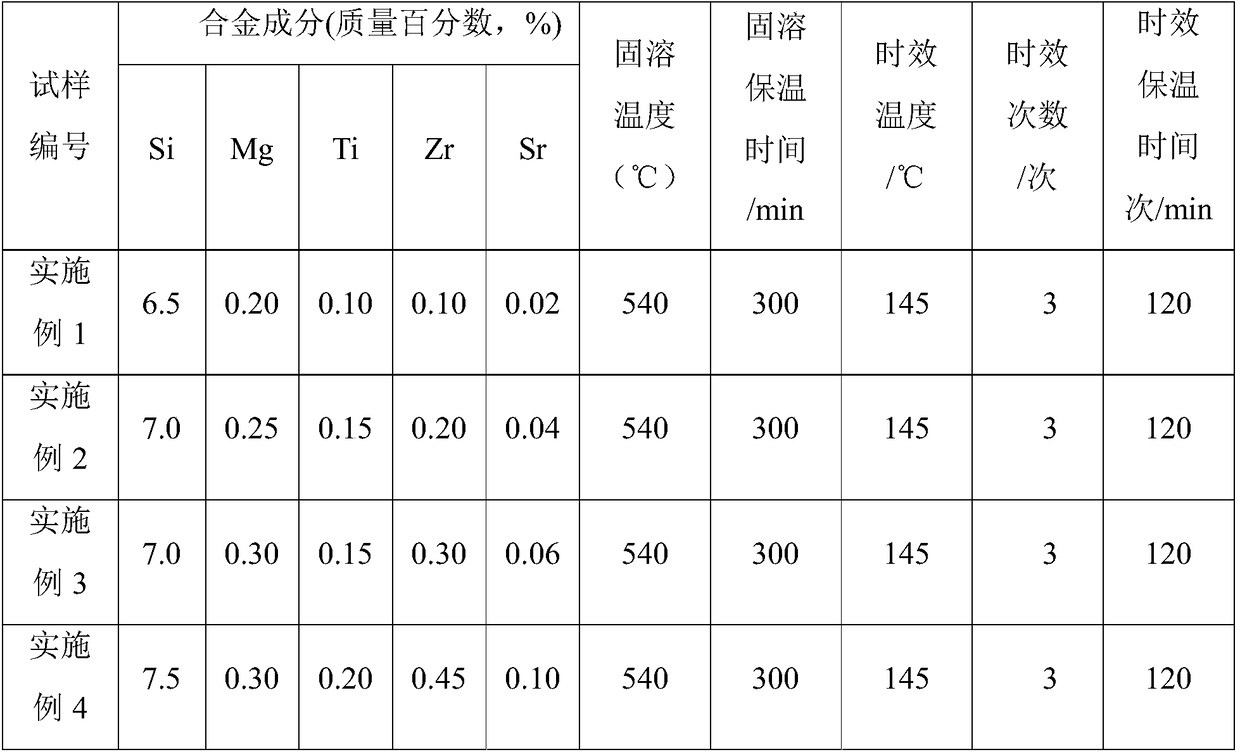

Embodiment 1

[0049] The preparation process of high-performance A356 aluminum alloy is as follows:

[0050] 1. Allocation of raw materials according to the target composition;

[0051]Weigh pure Al according to the mass percentage of 6.5% Si, 0.25% Mg, 0.10% Ti, 0.10% Zr, and 0.02% Sr in the alloy, Al-Si master alloy, Al-Mg master alloy, Al-Zr Master alloy, Al-Ti master alloy and Al-Sr master alloy.

[0052] 2. Melting and casting

[0053] (1) Add the Al-Si master alloy prepared and weighed in step 1 into a crucible preheated at 300°C, then raise the temperature to 730°C with the furnace, wait for it to completely melt, let it stand and keep it warm for 25 minutes.

[0054] (2) Add the Al-Mg master alloy, Al-Ti master alloy and Al-Zr master alloy prepared in step 1 into the melted alloy melt, wait until they are all melted, let stand and keep warm at 720°C for 15min, let stand After the end, add the weighed Al-Sr master alloy for modification treatment, fully stir and keep the heat for ...

Embodiment 2

[0064] In Examples 2 and 3, the content of Si element is increased to 7%, and the content of Mg element is increased to 0.25% and 0.30%, forming more finely dispersed Mg 2 Si phase, Zr element content and Ti element content are increased to 0.15%, 0.20% and 0.30% respectively, and grain refinement effect is obvious, therefore adopt " CZ-8000A electronic universal testing machine " to measure the resistance of the sample that embodiment 2 makes The tensile strength reached 302MPa, and the hardness of the sample was tested with a THBS-3000DS Brinell hardness tester, and the Brinell hardness was 101HBW. The tensile strength of the sample obtained in Example 3 reached 319MPa, and the Brinell hardness reached 105HBW. In Examples 2 and 3, the content of Sr element is increased to 0.04% and 0.06% respectively, and the effect of changing the distribution of the eutectic silicon phase is more obvious. Therefore, the elongation of the alloy after fracture is increased to 10% and 12%, res...

Embodiment 4

[0065] In Example 4, the Si element content is increased to 7.5%, the Mg element content is increased to 0.3%, the Ti element content is increased to 0.20%, the Sr element content is increased to 0.10%, and the Zr element content is increased to 0.45%. "CZ-8000A Electronic universal testing machine "measures the tensile strength of the sample obtained in Example 2 to reach 307MPa, and uses the THBS-3000DS type Brinell hardness tester to test the sample hardness, and the Brinell hardness is 99HBW, although Si, Mg, Ti, Sr elements in the alloy However, due to the increase of Zr element content to 0.45%, a large number of coarse primary Al3Zr phases are produced in the as-cast structure of the alloy, and the strength, hardness and elongation of the alloy decrease.

[0066] The highest tensile strength of the high-performance Al-Si alloy prepared by the present invention can reach 319MPa, and the Brinell hardness generally exceeds 100HBW, obviously exceeding the mechanical properti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com