Contact probe, measuring head, and manufacturing method for contact probe

A manufacturing method and test head technology, applied in the field of vertical probes, can solve the problems affecting the sliding degree of freedom of the probe, affecting the correct operation of the test head, contacting the probe card, etc., to achieve the characteristics of optimizing thermal conductivity and electrical conductivity as well as mechanical strength , good electrical and mechanical contact, the effect of small needle marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

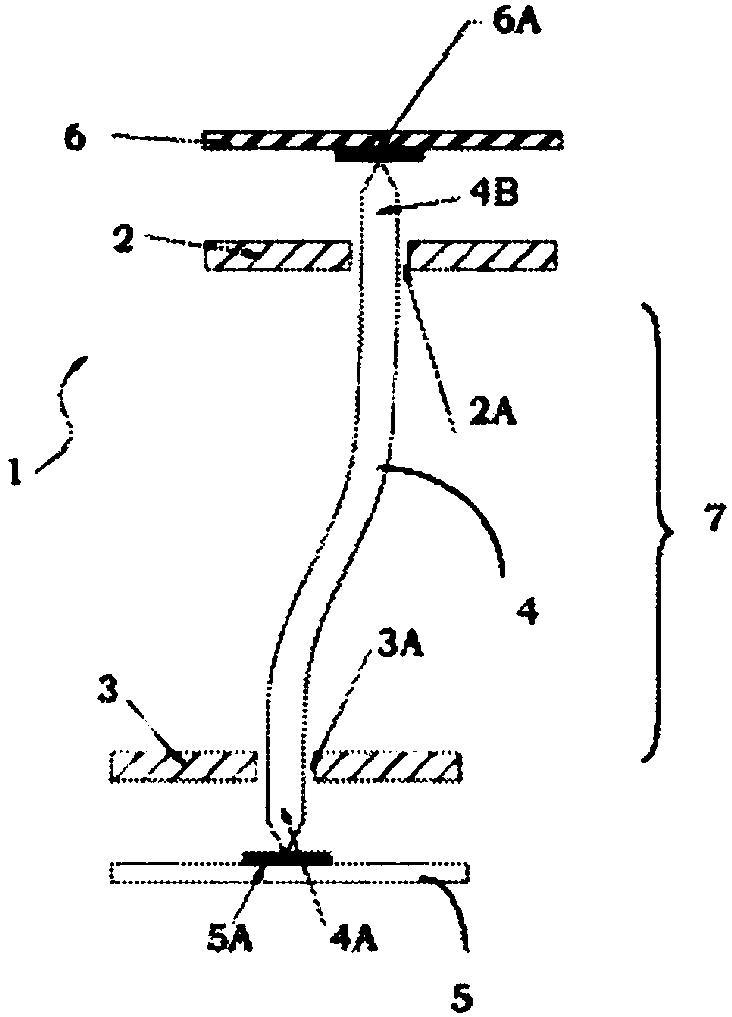

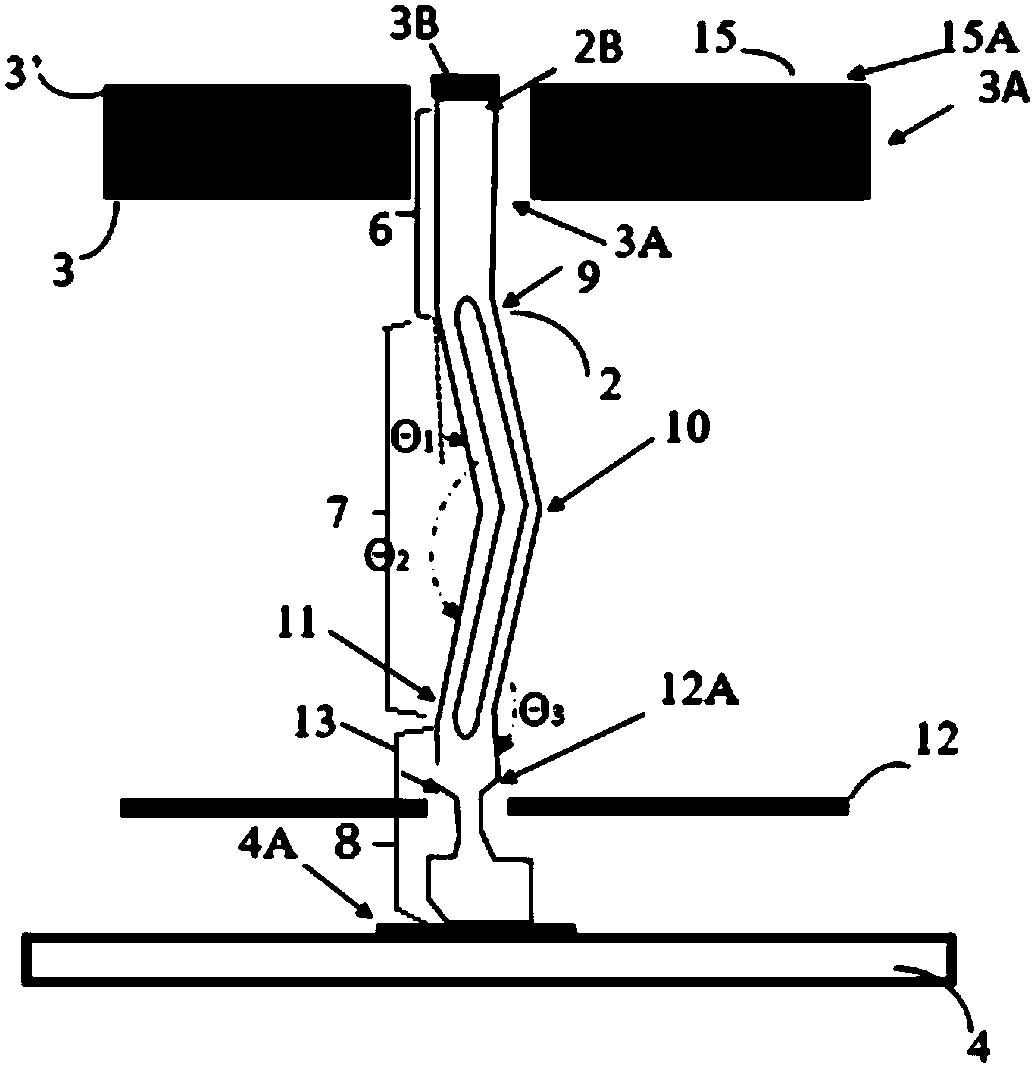

[0058] See attached figure 2 , 3 Shown, in particular, the contact probes of a test head of a device for testing electronic devices integrated on a wafer are described below.

[0059] It should be noted that these figures show a schematic view of a contact probe according to the invention and are not drawn to scale, on the contrary they are drawn to highlight important characteristics of the invention. In the figures, different parts are shown schematically, their shape can vary according to the desired application. Furthermore, measures described with respect to one embodiment and shown in one figure may also be used in other embodiments show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acute angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com