Vertical power diode with gradient-constituent drift-layers and fabrication method of vertical power diode

A technology of power diodes and drift layers, which is applied in the field of microelectronics, can solve the problems of device on-resistance and output current deterioration, uneven distribution of device electric field strength, and weaken the electric field strength of the drift layer, so as to avoid output current reduction and reverse The effect of effectively increasing the breakdown voltage and avoiding the increase of on-resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

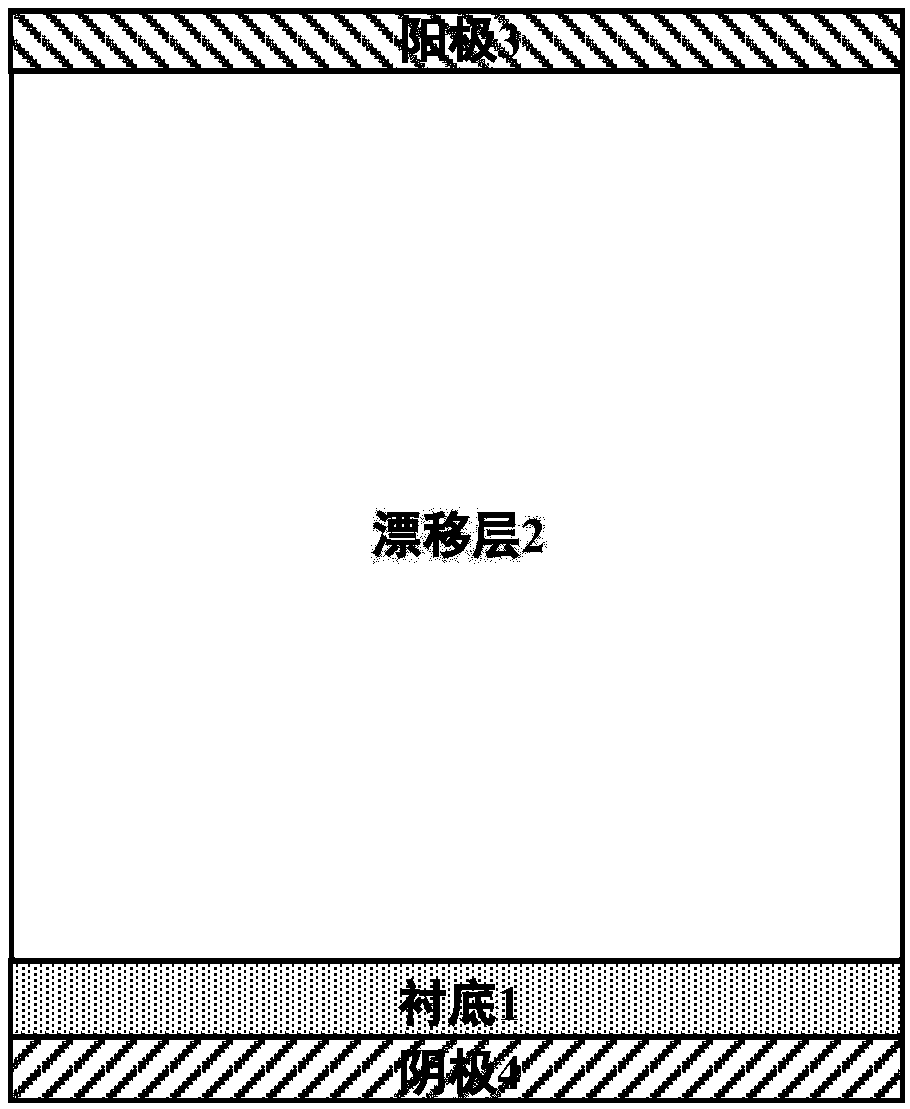

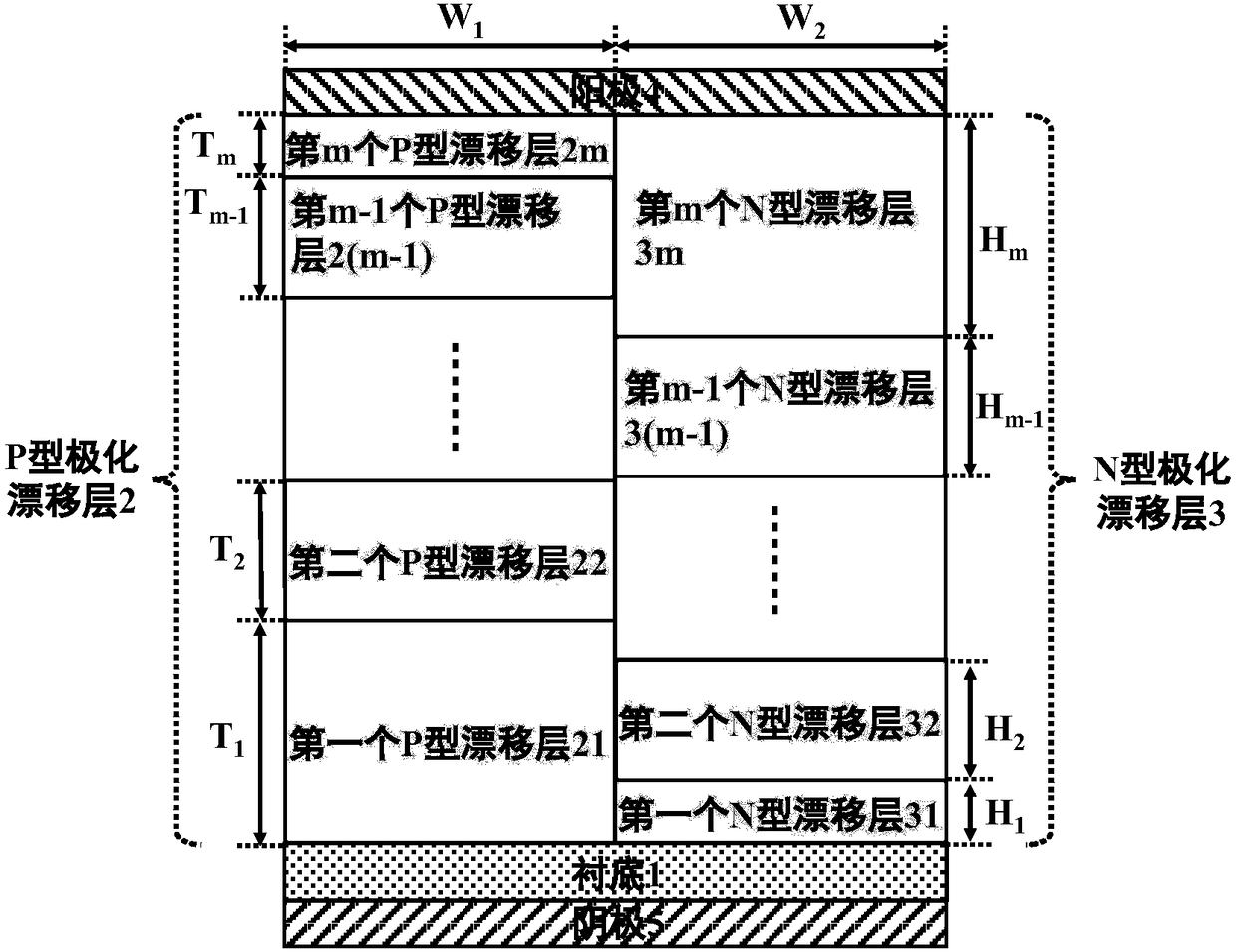

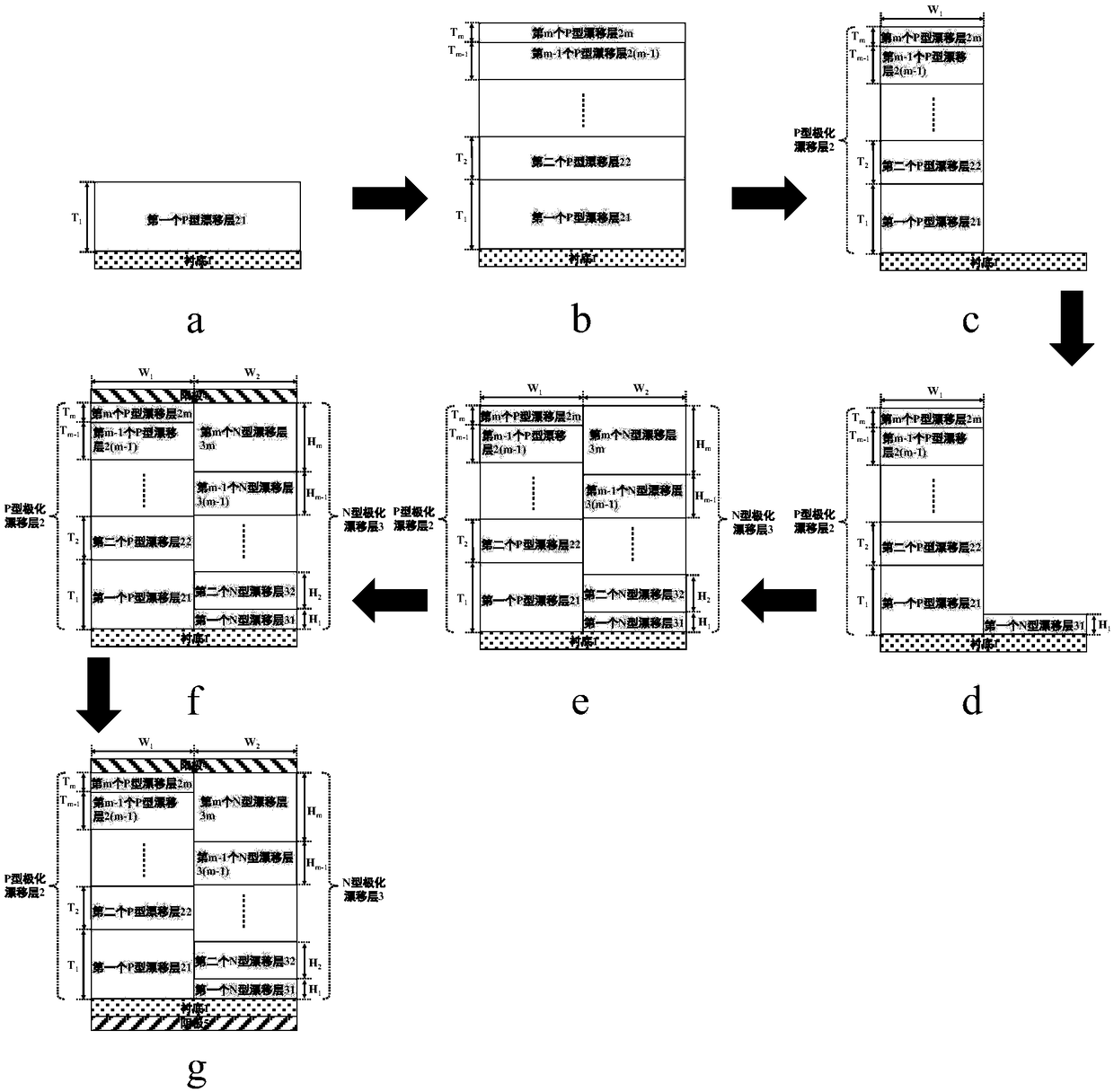

[0062] Embodiment 1: Manufacturing a drift layer vertical power diode with a gradient composition drift layer whose layer number m is 1.

[0063] Step 1. Fabricate a P-type polarization drift layer.

[0064] 1.1) Make the first layer of P-type drift layer, such as image 3 a.

[0065] in the use of n + AlGaN semiconductor material is epitaxially grown on a GaN substrate using metal-organic chemical vapor deposition to form a thickness T 1The first layer of P-type drift layer is 1.0 μm, the Al composition of the lower surface is 0, and the Al composition of the upper surface is 0.15, and the Al composition increases linearly from the lower surface to the upper surface of the layer;

[0066] The process conditions of metal-organic chemical vapor deposition technology are as follows: temperature is 980°C, pressure is 45Torr, flow rate of hydrogen gas is 4400 sccm, flow rate of ammonia gas is 4400 sccm, flow rate of gallium source is 35 μmol / min, flow rate of aluminum source in...

Embodiment 2

[0079] Embodiment 2: Fabricate a drift layer vertical type power diode with a gradient composition drift layer whose number m is 2.

[0080] Step 1. Fabricate a P-type polarization drift layer.

[0081] 1a) Make the first layer of P-type drift layer, such as image 3 a.

[0082] in the use of n + AlGaN semiconductor material is epitaxially grown on a substrate of GaN-type GaN using metal-organic chemical vapor deposition technology to form a thickness T 1 The first P-type drift layer is 1.0 μm, the Al composition of the lower surface is 0, and the Al composition of the upper surface is 0.1, and the Al composition increases linearly from the lower surface to the upper surface of the layer;

[0083] The process conditions of metal-organic chemical vapor deposition technology are as follows: temperature is 980°C, pressure is 45Torr, flow rate of hydrogen gas is 4000 sccm, flow rate of ammonia gas is 4000 sccm, flow rate of gallium source is 35 μmol / min, flow rate of aluminum s...

Embodiment 3

[0101] Embodiment 3: Fabricate a drift layer vertical type power diode with a gradient composition drift layer whose number m is 3.

[0102] Step A. Fabricate a P-type polarization drift layer.

[0103] A1) Make the first layer of P-type drift layer, such as image 3 a.

[0104] in the use of n + Metal-organic chemical vapor deposition technology was used on the substrate of GaN-type GaN at a temperature of 980°C, a pressure of 40 Torr, a flow rate of hydrogen gas of 3800 sccm, a flow rate of ammonia gas of 3800 sccm, a flow rate of gallium source of 30 μmol / min, and a flow rate of aluminum source of 5 μmol / min. Under the process conditions of linearly increasing to 7mol / min, the epitaxial AlGaN semiconductor material is formed to form a thickness T 1 The first P-type drift layer is 2.0 μm, the Al composition of the lower surface is 0, and the Al composition of the upper surface is 0.1, and the Al composition increases linearly from the lower surface to the upper surface of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com