Electron beam curing adhesive and preparation method and coating method thereof

An electron beam curing and adhesive technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of low temperature and fast drying, and achieve excellent adhesive effect and good use effect. , easy-to-update effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] The preparation method of the above-mentioned electron beam curing adhesive comprises the steps of:

[0070] 1) Add the main active resin, multifunctional curing agent and active solvent into the mixer, adjust the temperature to 20-100°C, preferably adjust the temperature to 30°C, keep constant temperature, stir and mix for 20-50 minutes;

[0071] 2) Add plasticizer and filler to the mixture obtained in 1), adjust the temperature to 20-100°C, keep constant temperature, stir and mix for 20-50 minutes;

[0072] Then add functional additives to the mixture obtained in step 2), adjust the temperature to 20-100° C., keep constant temperature, and stir and mix for 20-50 minutes.

[0073] Wherein, the functional additive can also be added simultaneously with the plasticizer and the filler in step 2), mainly determined according to the function and chemical and physical properties of the functional additive. It is easy to update and integrate existing production lines. In the...

specific Embodiment approach

[0081] The preferred specific implementation is as follows:

Embodiment approach 1

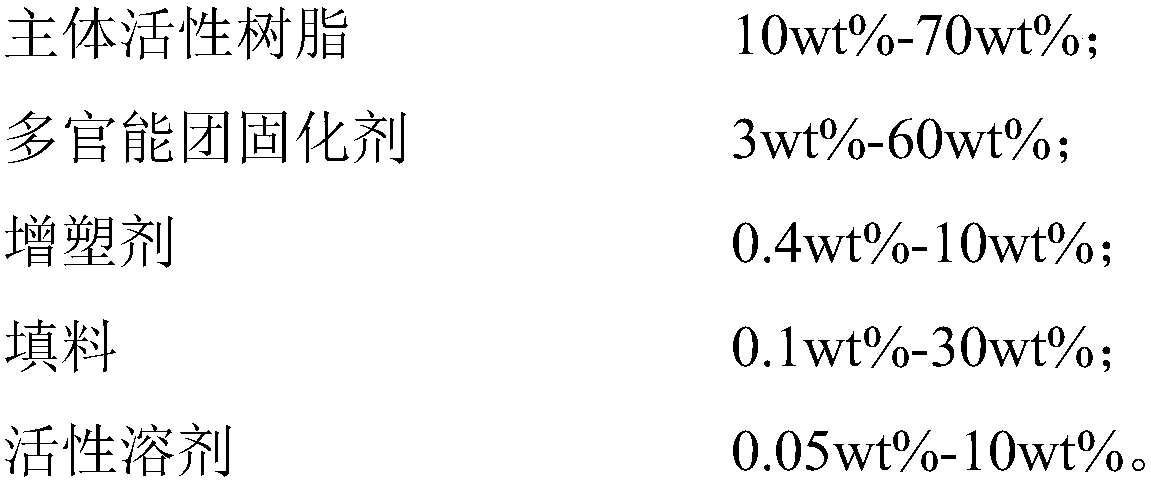

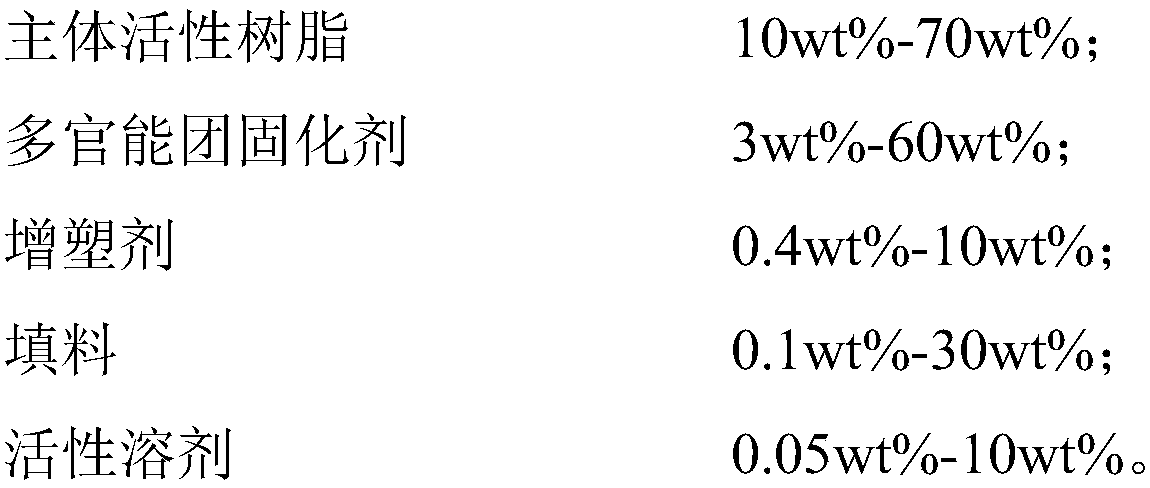

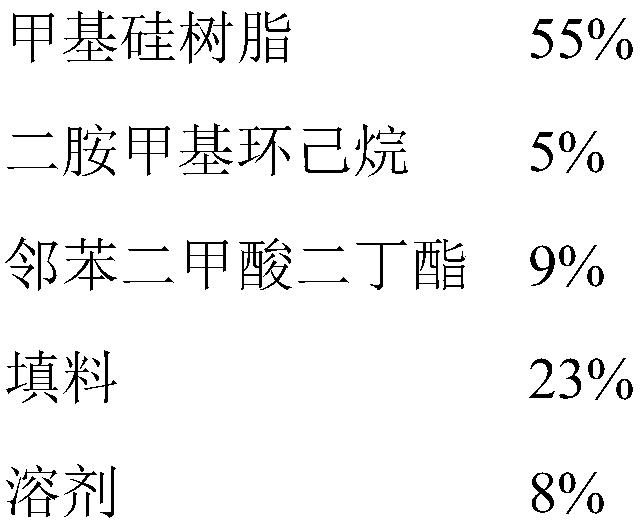

[0083] The adhesive is prepared according to the following composition ratio (mass percentage):

[0084]

[0085] The surface of the adherend (for example: PET) is treated, and the silicone resin adhesive is mixed evenly according to the above ratio. After pre-mixing for one hour, the glue is applied, followed by EB curing, and finally compounded.

[0086] Example effects: curing temperature 30°C, VOC emission 15%, curing time 20h, low temperature resistance -150°C, high temperature resistance 200°C, tensile strength 25Mpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com