Multifunctional water-permeable structure pavement

A multi-functional, top-surface technology, applied in the direction of condensable pavement, roads, roads, etc. paved on site, can solve the problems of unsatisfactory water purification effect, low photocatalytic efficiency, limited range, etc., and achieve increased absorption of visible light. The effect of improving the photocatalytic efficiency and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

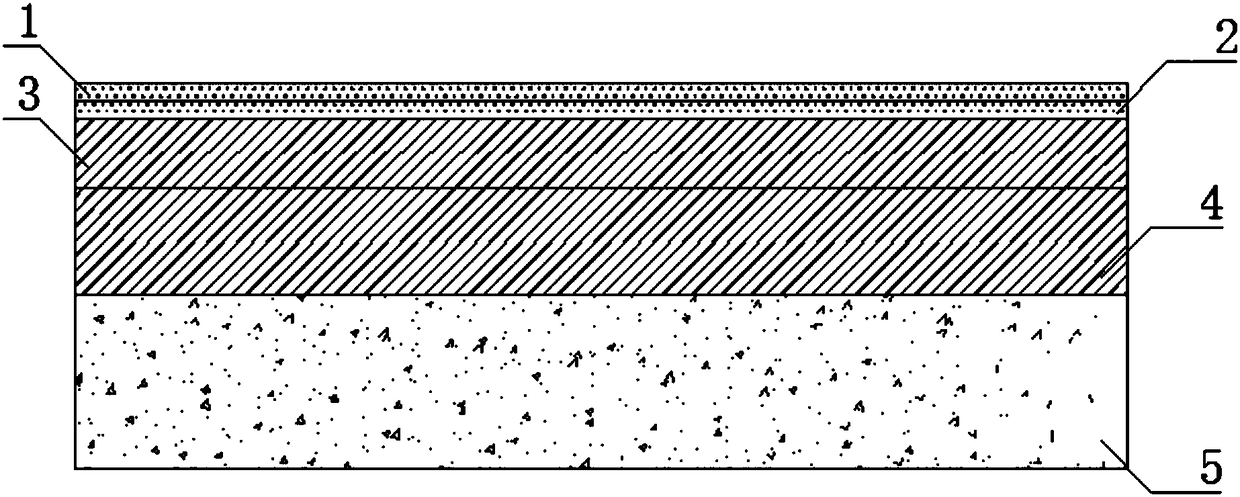

[0048] Base layer 5 is a permeable concrete layer with 200-mesh activated carbon as water purification material, and the dosage is 1% of the concrete mass; the particle size of coarse aggregate (single-size graded crushed stone) is 16-19mm, and the dosage is 1600kg / m 3 ; Ordinary Portland cement 42.5 for concrete, the dosage is 375kg / m 3 , the water-cement ratio is 0.28; the reinforcing agent is 1% of the concrete mass.

[0049] The modified asphalt is made of RE-G40 high-viscosity asphalt modifier and SBS asphalt at a mass ratio of 8:92, and the dynamic viscosity at 60°C is 13000Pa.s.

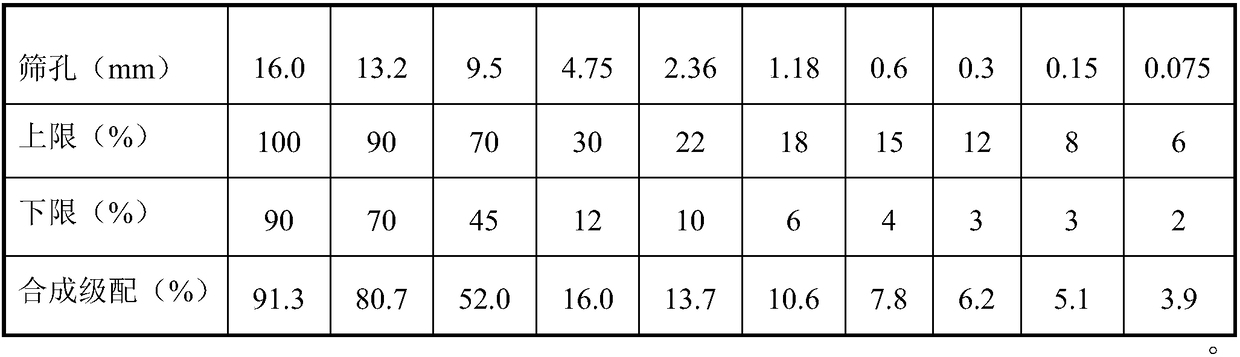

[0050] Mixed asphalt concrete A layer 3: the asphalt ratio of modified asphalt and stone material A is preferably 4.8%, the mass proportion of polyester fiber is 2%, the porosity of the surface layer is 18%, and the gradation of mineral material A is shown in the table below 1:

[0051]

[0052]

[0053] Table 1

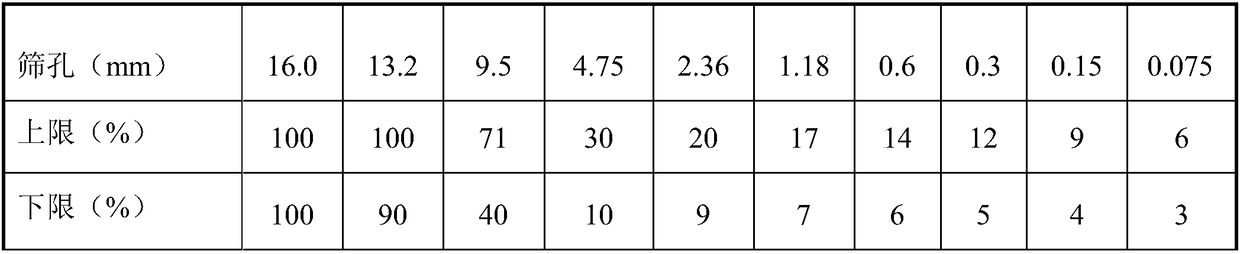

[0054] Mixed asphalt concrete B layer 4: the ratio of modified asphalt ...

Embodiment 2

[0061] The base layer 5 uses 100-mesh activated carbon as the permeable concrete layer of the water purification material, and the dosage is 3% of the concrete mass; the particle size of the coarse aggregate (single-size graded crushed stone) is 16-19mm, and the dosage is 1600kg / m 3 ; Ordinary Portland cement 42.5 for concrete, the dosage is 375kg / m 3 , the water-cement ratio is 0.32; the reinforcing agent is 3% of the concrete mass.

[0062] All the other components and their contents are the same as in Example 1.

[0063] After testing, the water permeability coefficient of the structured pavement of Example 2 is 31ml / s.

[0064] The water permeability coefficient represents the water permeability of the pavement structure. It can be seen that the water permeability coefficients of Examples 1 and 2 are both greater than 600mL / min, and the results show that the water permeability is excellent and the water permeability effect is obvious.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com