Distributed Bragg reflector applied into vertical-cavity surface-emitting laser

A technology of Bragg reflector and vertical cavity surface emission, which is applied in the direction of lasers, laser components, semiconductor lasers, etc., can solve problems such as unfavorable, complicated growth process, and difficult to control the growth process, and achieve simplified structure design and growth parameters. more controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

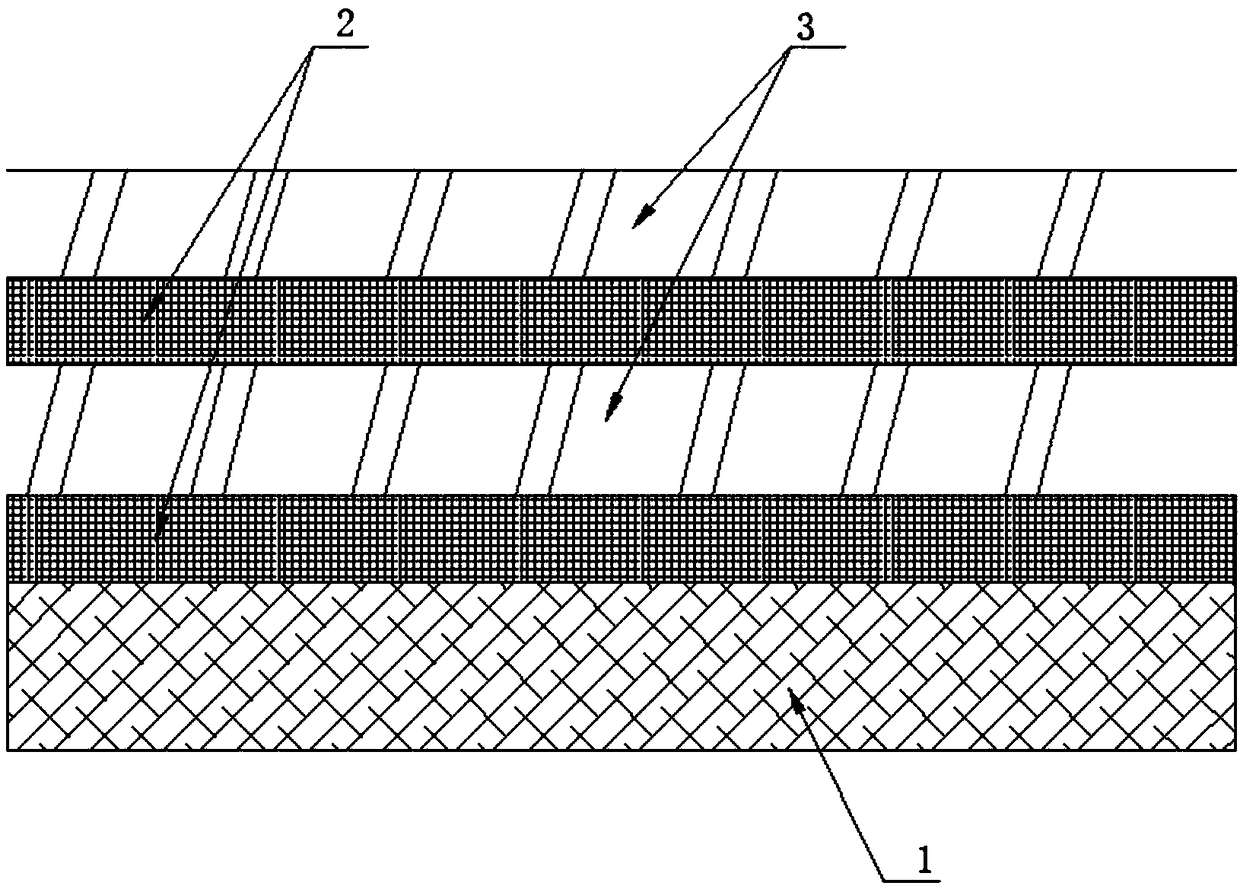

[0020] Example 1, the thickness of the DBR mirror in one period is 850nm, and the total optical thickness at the quarter wavelength is The low refractive index material layer 3 of AIAs is The superlattice thickness of the binary digital alloy GaAs / AIAs is The number of superlattice pairs is 15;

example 2

[0021] Example 2, the thickness of the DBR mirror in one period is 940nm, and the total optical thickness at the quarter wavelength is The low refractive index material layer 3 of AIAs is The superlattice thickness of the binary digital alloy GaAs / AIAs is The number of superlattice pairs is 17.

[0022] As a DBR reflector applied in a vertical cavity surface emitting laser, the DBR reflector provided by the present invention can be used as a P-type or N-type DBR reflector therein.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com