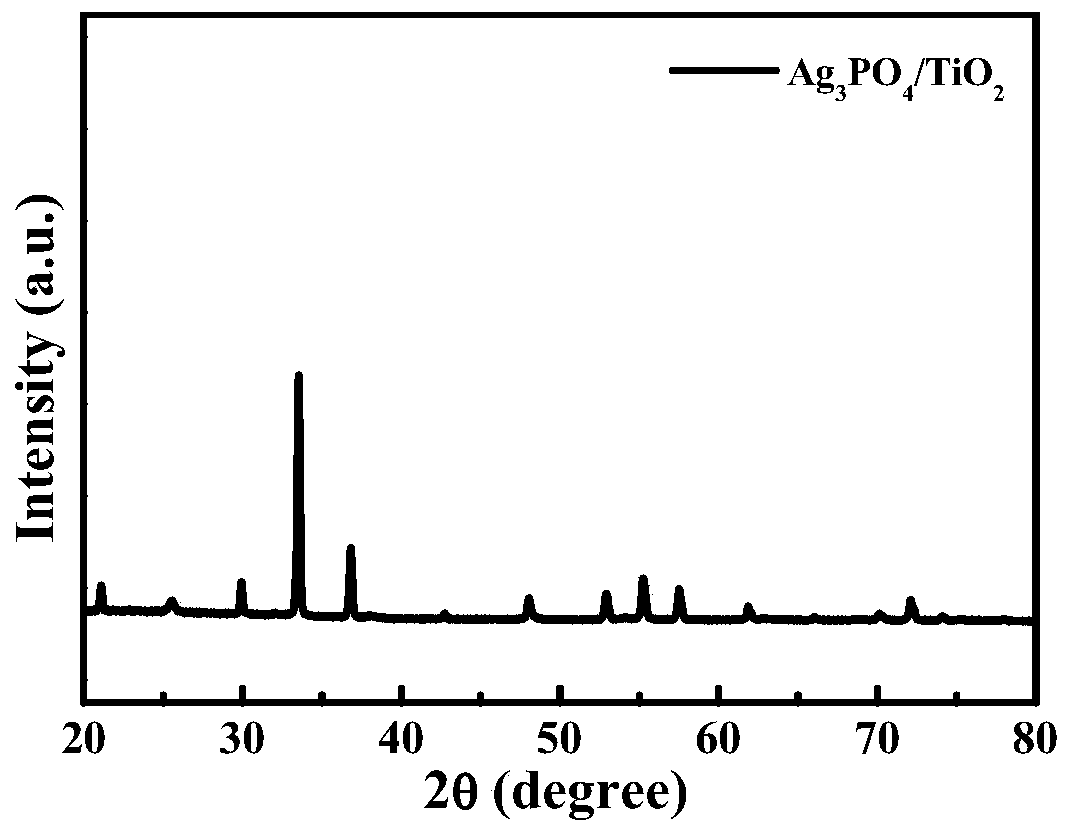

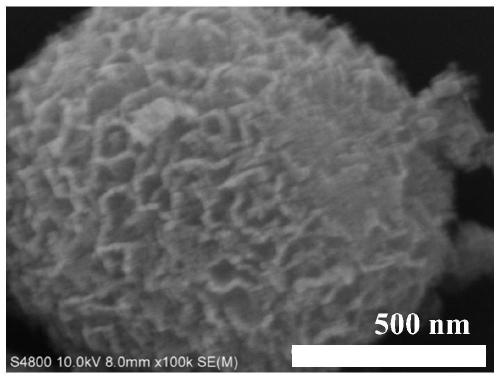

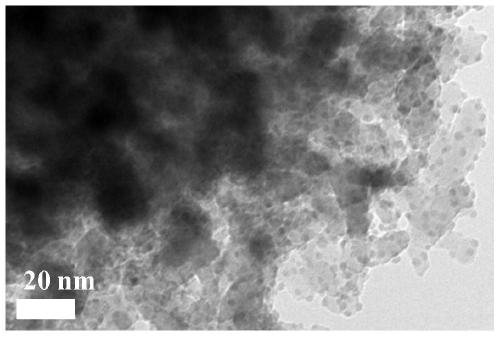

A kind of ultramicronano silver phosphate/titanium dioxide nanoflower composite material and its preparation method and application

A technology of titanium dioxide and composite materials, applied in the fields of nanomaterials and photocatalysis, can solve the problems of insufficient light absorption of titanium dioxide, difficult recovery of photocatalysts, poor stability of silver phosphate, etc., and achieves improved photocatalytic performance, increased scattering performance, and increased adsorption sites. and the effect of reactive sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Step 1: Add 0.025 mL of diethylenetriamine (EDTA) to 31.5 mL of isopropanol, and stir for 10 min. Then, 1.125 mL of diisopropyl di(acetylacetonato)titanate was added to the solution. Stirring was continued for 10 min. The resulting mixed solution was poured into a reaction kettle, and subjected to solvent heat treatment at 200° C. for 24 hours. After the reaction, the precipitate was washed three times with deionized water and absolute ethanol, placed in a 60°C oven, dried for 24 hours, and finally the reactant was placed in a muffle furnace with a heating rate of 1°C / min and a heat treatment temperature of 550°C , and annealed for 2 hours to obtain the precursor titania nanoflower material.

[0023] Step 2: Step 2: Stir and disperse 100mg of the precursor titanium dioxide nanoflower material in 30mL of ethanol, and disperse it evenly with moderate ultrasound; weigh 200mg of silver nitrate and dissolve it in a solution of ammonia water with a mass fraction of 1% and a...

Embodiment 2

[0028]Step 1: Add 0.025 mL of diethylenetriamine (EDTA) to 31.5 mL of isopropanol, and stir for 10 min. Then, 1.125 mL of diisopropyl di(acetylacetonato)titanate was added to the solution. Stirring was continued for 10 min. The resulting mixed solution was poured into a reaction kettle, and subjected to solvent heat treatment at 200° C. for 24 hours. After the reaction, the precipitate was washed three times with deionized water and absolute ethanol, placed in a 60°C oven, dried for 24 hours, and finally the reactant was placed in a muffle furnace with a heating rate of 1°C / min and a heat treatment temperature of 550°C , and annealed for 2 hours to obtain the precursor titania nanoflower material.

[0029] Step 2: Step 2: Stir and disperse 100mg of the precursor titanium dioxide nanoflower material in 30mL of ethanol, and disperse it evenly with moderate ultrasound; weigh 400mg of silver nitrate and dissolve it in a solution of ammonia water with a mass fraction of 2% and a ...

Embodiment 3

[0033] Step 1: Add 0.125 mL of diethylenetriamine (EDTA) to 31.5 mL of isopropanol, and stir for 10 min. Then, 4.5 mL of diisopropyl di(acetylacetonato)titanate was added to the solution. Stirring was continued for 10 min. The resulting mixed solution was poured into a reaction kettle, and subjected to solvent heat treatment at 220° C. for 24 hours. After the reaction, the precipitate was washed three times with deionized water and absolute ethanol, placed in a 60°C oven, dried for 24 hours, and finally placed in a muffle furnace with a heating rate of 10°C / min and a heat treatment temperature of 550°C , and annealed for 2 hours to obtain the precursor titania nanoflower material.

[0034] Step 2: Step 2: Stir and disperse 100mg of the precursor titanium dioxide nanoflower material in 30mL of ethanol, and disperse it evenly with moderate ultrasound; weigh 200mg of silver nitrate and dissolve it in a solution of ammonia water with a mass fraction of 1% and a volume of 10ml, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com