A kind of preparation method of master batch for water conservancy project floating

A technology for water conservancy engineering and flotation, which is applied in the field of preparation of masterbatches for flotation in water conservancy projects, can solve the problems of reduced buoyancy, heavy water absorption, easy growth of some planktonic seaweed, etc., so as to prolong the service life, not easy to absorb water, and avoid adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

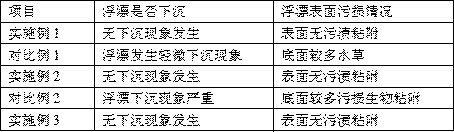

Examples

Embodiment 1

[0018] A method for preparing a masterbatch for water conservancy engineering floats, comprising the following steps:

[0019] (1) In parts by weight, 34 parts of zinc nitrate hexahydrate and 21 parts of sodium metavanadate were added to 55 parts of deionized water, and the mixture was added to a stainless steel reactor, and the temperature of the reaction was controlled to be 110°C. After holding the reaction for 4 hours, cool to room temperature, centrifuge to obtain the precipitate, dry the precipitate, and calcinate at 650°C for 30 minutes to obtain nano-zinc vanadate;

[0020] (2) In parts by weight, 55 parts of N-isopropylacrylamide and 8 parts of trifluoroethyl acrylate were added to the reaction vessel, and then 34 parts of deionized water, 1 part of emulsifier, 2 parts of Azobisisobutyronitrile, 9 parts of nano-zinc vanadate, 1 part of organic pigment toner (color can be adjusted according to needs), after mixing and stirring evenly, raise the temperature of the mixtu...

Embodiment 2

[0028] A method for preparing a masterbatch for water conservancy engineering floats, comprising the following steps:

[0029] (1) In parts by weight, add 36 parts of zinc nitrate hexahydrate and 23 parts of sodium metavanadate to 58 parts of deionized water, add the mixture into a stainless steel reactor, and control the reaction temperature to 115°C. After heat preservation reaction for 4.5 hours, cool to room temperature, centrifuge to obtain precipitate, dry the precipitate, and calcine at 655°C for 35 minutes to obtain nano-zinc vanadate;

[0030] (2) In parts by weight, add 58 parts of N-isopropylacrylamide and 10 parts of trifluoroethyl acrylate into the reaction vessel, then add 36 parts of deionized water, 2 parts of emulsifier, 3 parts of Azobisisobutyronitrile, 10 parts of nano-zinc vanadate, 3 parts of organic pigment toner (color can be adjusted according to needs), after mixing and stirring evenly, raise the temperature of the mixture to 70°C, keep it warm for 3....

Embodiment 3

[0038] A method for preparing a masterbatch for water conservancy engineering floats, comprising the following steps:

[0039] (1) In parts by weight, add 40 parts of zinc nitrate hexahydrate and 25 parts of sodium metavanadate to 60 parts of deionized water, add the mixture into a stainless steel reactor, and control the reaction temperature to 120°C. After heat preservation reaction for 5 hours, cool to room temperature, centrifuge to obtain precipitate, dry the precipitate, and calcine at 660°C for 40 minutes to obtain nano-zinc vanadate;

[0040] (2) In parts by weight, add 60 parts of N-isopropylacrylamide and 12 parts of trifluoroethyl acrylate into the reaction vessel, then add 40 parts of deionized water, 3 parts of emulsifier, 4 parts of Azobisisobutyronitrile, 11 parts of nano-zinc vanadate, 4 parts of organic pigment toner (color can be adjusted according to needs), after mixing and stirring evenly, raise the temperature of the mixture to 72°C, keep it warm for 4 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com