Method for industrially improving storage stability of transglutaminase

A technology of transglutaminase and transglutaminase enzyme, which is applied in the field of improving the storage stability of transglutaminase in industry, can solve the problems of enzyme activity and thermal stability decline, enzyme activity decline, etc. Achieve the effect of being conducive to industrial application, short time consumption, and improving storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Take 200mL of the transglutaminase fermentation broth produced by Streptomyces Maoyuan with an enzyme activity of 30U / mL, add 1:1 (v / v) ethanol precipitation fermentation broth, let stand at room temperature for 10min, centrifuge, discard The supernatant was spray-dried (inlet air temperature 160°C, feed rate 25mL / min, compressed air flow rate 200NL / min, outlet air temperature 65°C) to obtain transglutaminase enzyme preparation powder.

[0041] Measure its enzyme activity, measure its enzyme activity after standing at 37°C for one month, and calculate the degree of decrease in enzyme activity.

Embodiment 2

[0043] Compared with Example 1, add 2.5% (w / w) amino acid to the supernatant precipitate after ethanol precipitation, mix well, let stand for 30min, and then carry out spray drying; other steps and parameters are the same as those in Example 1 unanimous.

[0044] Take 200mL of the transglutaminase fermentation broth produced by Streptomyces Maoyuan with an enzyme activity of 30U / mL, add 1:1 (v / v) ethanol precipitation fermentation broth, let stand at room temperature for 10min, centrifuge, discard Supernatant, weigh the precipitate, add 2.5% (w / w) amino acid, mix well, let stand for 30min, and then carry out spray drying (inlet air temperature 160°C, feed rate 25mL / min, compressed air flow 200NL / min , air outlet temperature 65° C.), to obtain transglutaminase enzyme preparation powder.

[0045] Measure its enzyme activity, measure its enzyme activity after standing at 37°C for one month, and calculate the degree of decrease in enzyme activity.

Embodiment 3

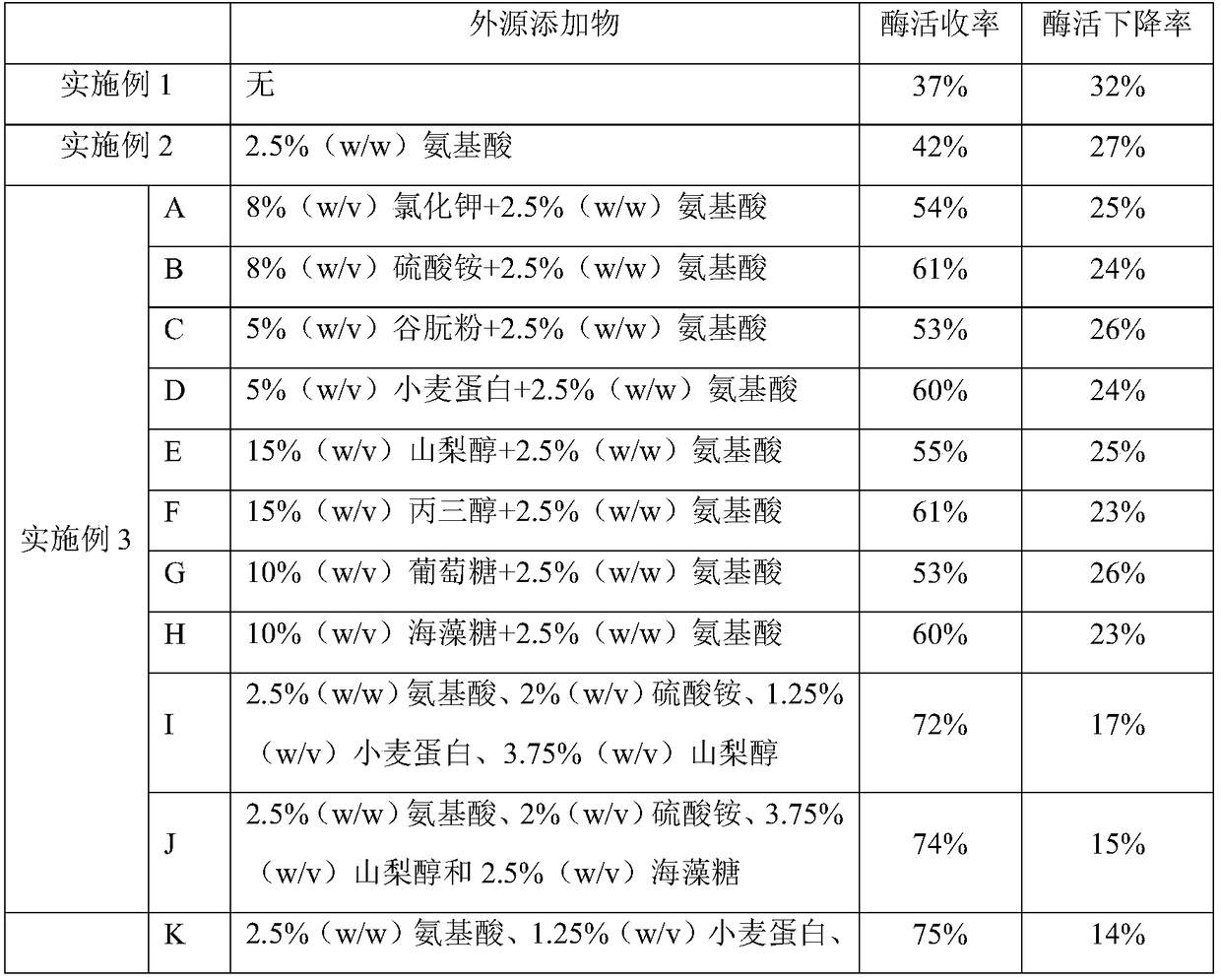

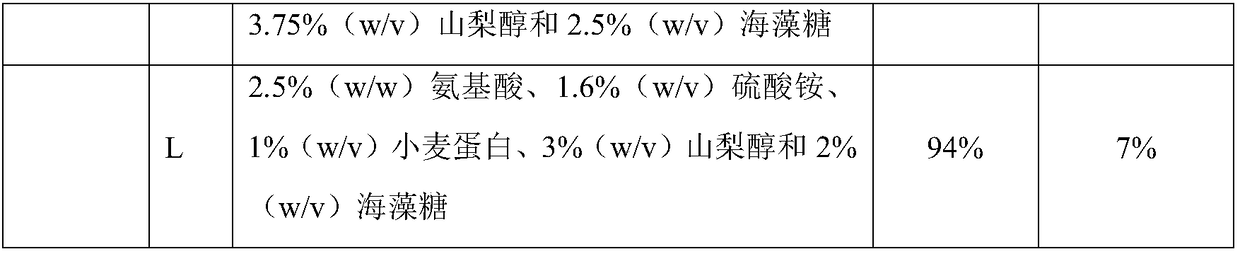

[0047] Compared with Example 2, different exogenous additives or combinations of exogenous additives are added to the fermentation broth, stirred until completely dissolved, left to stand for a period of time, and then subsequent steps such as ethanol precipitation are performed; and other steps and parameters are the same as Example 2 is consistent. specifically:

[0048] Take 200 mL of transglutaminase fermentation broth produced by Streptomyces Maoyuan with an enzyme activity of 30 U / mL, add one or more exogenous additives, stir until completely dissolved, and let stand for 30 minutes. Add 1:1 (v / v) ethanol precipitation fermentation broth, let stand at room temperature for 10min, centrifuge, discard the supernatant, weigh the precipitate, add 2.5% (w / w) amino acid, mix well, let stand for 30min, then Spray drying (inlet air temperature 160°C, feed rate 25mL / min, compressed air flow rate 200NL / min, outlet air temperature 65°C) to obtain transglutaminase preparation powder....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com