Double-belt clamping desemping machine

A technology of hemp machine and belt clamp, which is applied in the direction of harvester, threshing equipment, mechanical processing, etc., can solve the problems of low degree of automation, complex structure, poor reliability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Below in conjunction with accompanying drawing, the clam of the present invention is made into the following description.

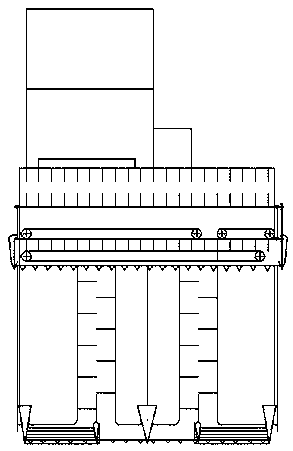

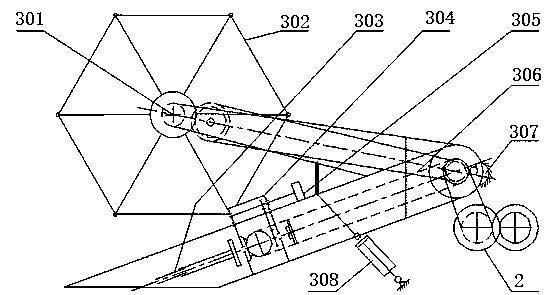

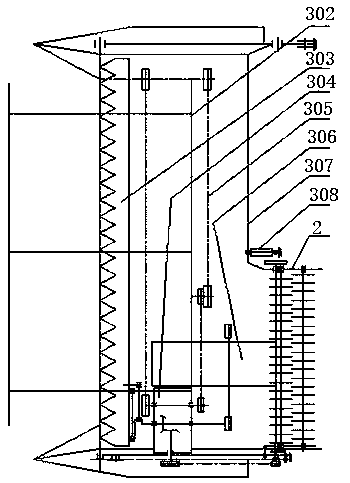

[0055] Such as figure 1 , figure 2 , image 3 The double-harvester ramie fiber-feeding double-harvesting combine shown in the figure consists of a vertical header 1, a shredder 2, a horizontal header 3, a control system 4, a power and power transmission system 5, a hemp removing machine 6, and a feed Storehouse 7, fiber storehouse 8, walking system 9 forms.

[0056] The horizontal header 3 and the vertical header 1 are arranged in the front, the shredder 2 is arranged in the upper right front, and the desemping machine is arranged in the upper right rear of the middle, and the horizontal header 3 and the shredder 2 are composed The hemp shoot (leaf) combined harvesting system, the vertical header 1 and the hemp threshing machine 6 form the hemp stalk fiber combined harvesting system, the control system 4, the engine and the power transmission s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com