Carcass decontamination method used in cattle and sheep slaughtering process

A carcass, cattle and sheep technology, applied in the field of cattle and sheep carcass bacteria reduction operation process, can solve the problems of economic loss, distance and time increase, odor, etc., and achieve the effect of ensuring cleanliness and safety and reducing pollution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

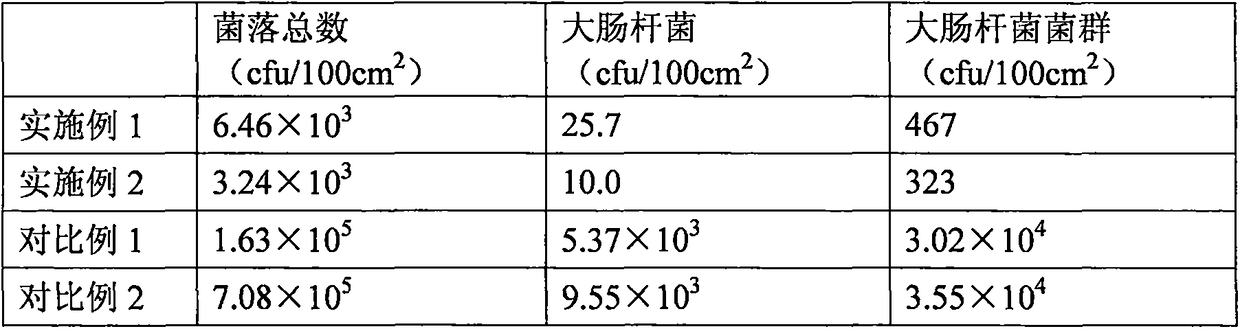

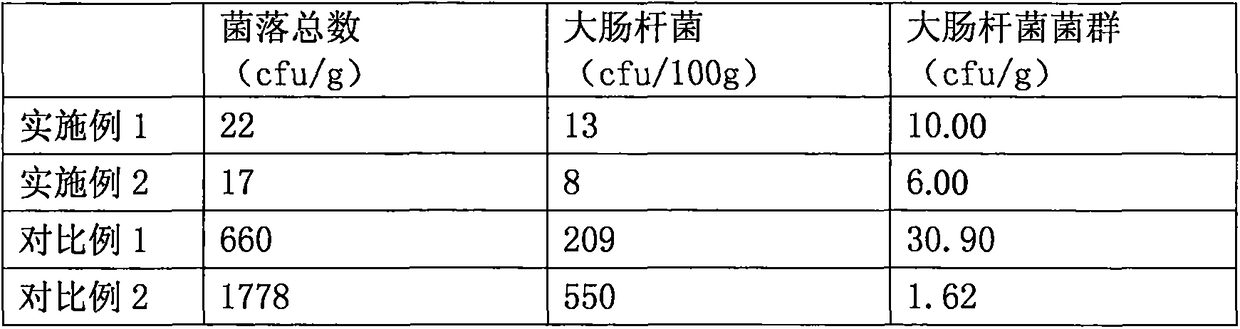

[0018] Embodiment 1, carcass bacteria reduction method in cattle and sheep slaughtering process

[0019] The method for carcass bacteria reduction in the process of slaughtering cattle and sheep, the operation steps are as follows:

[0020] (1) Disinfection of live animal fur: at the channel opening where cattle and sheep enter the slaughter room, use 0.20-0.3 MPa water pressure to spray 3-7% lactic acid liquid on the animal hair at the channel opening, and each live sheep Spray 70-150mL lactic acid liquid, spray 150-300mL lactic acid liquid for each live sheep, and wait for slaughter after 10-15 minutes of spray disinfection time;

[0021] (2) Carcass hot water pasteurization: the slaughtered cattle and sheep carcasses are heat-sterilized by a hot pasteurizer, and the parameters of the pasteurizer are: water temperature 70-90°C, time 6-12 seconds; and then carry out Carcass steam sterilization in the next step;

[0022] (3), carcass steam sterilization: cattle and sheep car...

Embodiment 2

[0025] Embodiment 2, carcass bacteria reduction method in cattle and sheep slaughtering process

[0026] The method for carcass bacteria reduction in the process of slaughtering cattle and sheep, the operation steps are as follows:

[0027] (1) Disinfection of live animal fur: at the channel opening where cattle and sheep enter the slaughter room, use 0.20-0.3 MPa water pressure to spray lactic acid liquid with a mass concentration of 3-7% on the animal hair at the channel opening. Spray 70-150mL lactic acid liquid, spray 150-300mL lactic acid liquid for each live sheep, and wait for slaughter after 10-15 minutes of spray disinfection time;

[0028] (2) Carcass ozone and hot water pasteurization: Fill the pasteurizer with ozone gas with a volume concentration of 5.0-10.0%, and the slaughtered cattle and sheep carcasses are sterilized by ozone gas and heat through the hot pasteurizer For processing, the setting parameters of the pasteurization machine are: water temperature 70...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com