Preparation method of low oxalic acid ultrafine green tea powder

A kind of green tea powder and ultra-fine technology, which can be used in tea treatment before extraction, etc., can solve the problem of high oxalic acid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

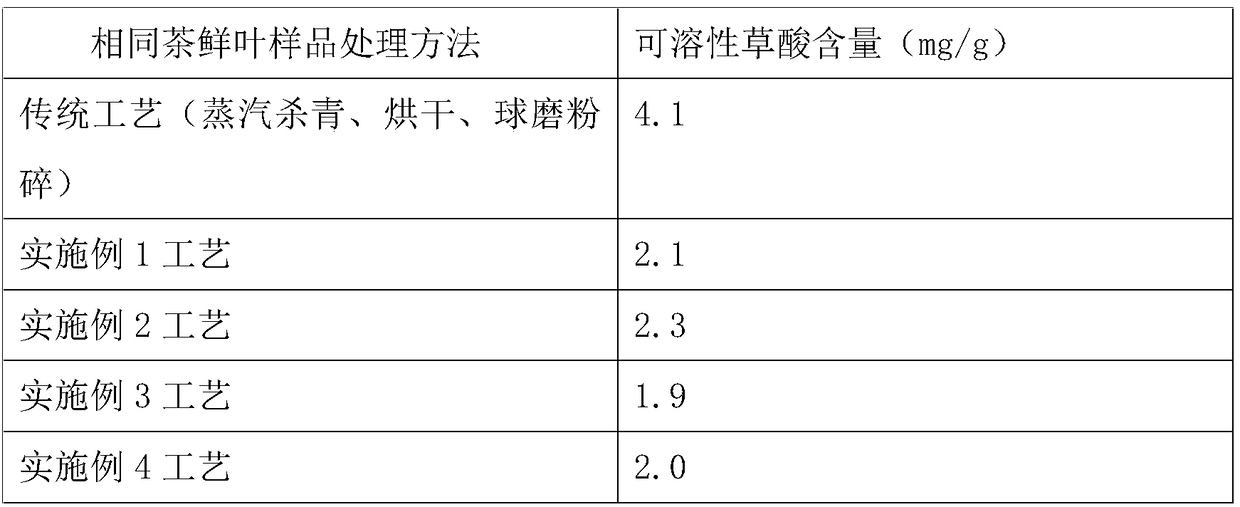

Examples

Embodiment 1

[0024] A preparation method of low oxalic acid superfine green tea powder, comprising the following steps:

[0025] a) Immerse the fresh raw material of the tea tree in 30 times the mass of boiling water, take it out quickly after keeping it in a boiling state for 20 seconds, and quickly cool the tea leaves with 0-5 ℃ low temperature water with 30 times the mass;

[0026] b) Mix the cooled tea leaves with low-temperature pure water at 0-5°C, the ratio of tea leaves to water is 1:5, and grind into a coarse slurry with a colloid mill, which passes through a 60-mesh sieve;

[0027] c) The coarse slurry is further processed with an ultra-high pressure homogenizer with a pressure of 20,000 psi to achieve the effect of ultra-fine crushing, and the particle size fineness reaches 1000-3000 mesh;

[0028] d) UHT sterilizes the tea slurry after ultrafine crushing at a temperature of 120-140° C. for 12 seconds;

[0029] e) The sterilized tea slurry is spray-dried at an inlet air tempera...

Embodiment 2

[0031] A preparation method of low oxalic acid superfine green tea powder, comprising the following steps:

[0032] a) Immerse the tender buds of the tea tree in 10 times the mass of boiling water, keep it in a boiling state for 10 seconds, then quickly take it out, and use 10 times the mass of 5-10°C low-temperature water to quickly cool the tea leaves;

[0033] b) Mix the cooled tea leaves with low-temperature pure water at 5-10°C, the ratio of tea leaves to water is 1:1.5, grind into a coarse slurry with a wet refiner, and pass the coarse slurry through an 80-mesh sieve.

[0034] c) The coarsely ground slurry is further processed with a high-pressure micro-jet homogenizer with a pressure of 30,000 psi to achieve the effect of ultrafine crushing;

[0035] d) After the ultrafine crushed tea slurry is packaged in a flexible package, in a closed ultra-high pressure container, water is used as a medium to apply a pressure of 500 MPa to sterilize;

[0036] e) After the sterilize...

Embodiment 3

[0038] A preparation method of low oxalic acid superfine green tea powder, comprising the following steps:

[0039] a) Immerse the fresh products of 1 bud and 1 leaf and 1 bud and 2 leaves of the tea tree in boiling water of 15 times the mass, keep it in the boiling state for 15 seconds, then take it out quickly, and use 0-℃ low-temperature water of 15 times the mass to quickly cool the tea leaves;

[0040] b) Mix the cooled tea leaves with low-temperature pure water at 0-5°C, the ratio of tea leaves to water is 1:2, grind into a coarse slurry with a colloid mill, and pass the coarse slurry through a 60-mesh sieve;

[0041] c) The coarsely ground slurry is further processed with a high-pressure micro-jet homogenizer with a pressure of 40,000 psi to achieve the effect of ultrafine crushing;

[0042] d) The tea slurry after ultrafine crushing is sterilized by UHT. The temperature is 120°C to 140°C, and the time is 12 seconds;

[0043] e) After the sterilized tea slurry is froz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com