Water-soluble fertilizer containing carbon-enzyme polypeptide and preparation method of water-soluble fertilizer

A water-soluble fertilizer and carbon enzyme technology, which is applied in fertilization methods, organic fertilizers, sewage/sludge fertilizers, etc., can solve the problem that the production of bacterial species and bacterial fertilizers is not disclosed, production and manufacturing are difficult to achieve, and the name and number of biological bacterial fertilizers And the process is not fully disclosed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

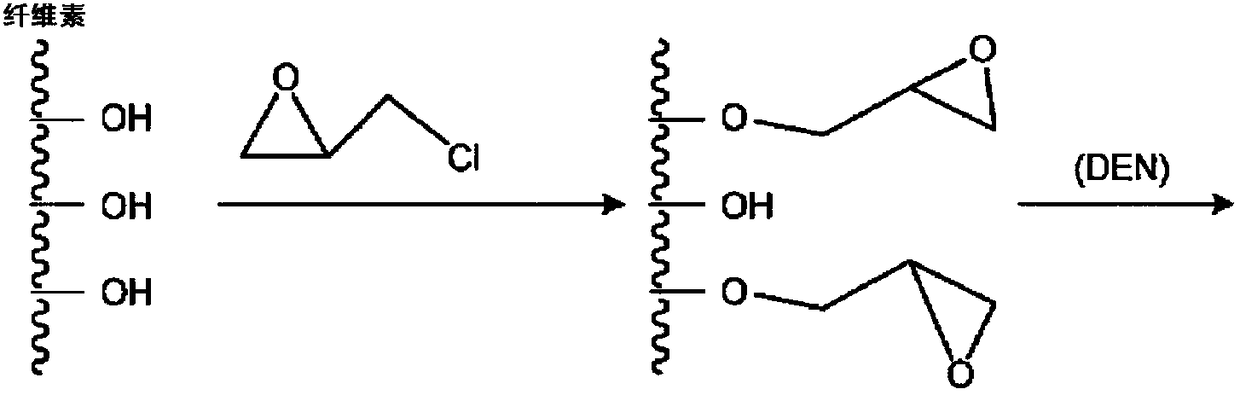

Method used

Image

Examples

Embodiment 1

[0052] A water-soluble fertilizer containing carbonase polypeptide, the raw material components and weight ratio of the water-soluble fertilizer are: 45 parts of polycarbase, 10 parts of citric acid, 150 parts of organic material extract, 20 parts of trace elements, and 30 parts of additives , 20 parts of polypeptide, 500 parts of waste liquid, and 100 parts of chemical fertilizer.

[0053] The raw material components and weight ratio of the organic material extract are: 10 parts of cotton meal, 15 parts of corn germ meal, 5 parts of peanut meal, 50 parts of plant straw, 20 parts of bagasse, 15 parts of traditional Chinese medicine bagasse, edible fungus 10 parts of dregs, 5 parts of rice husks, 10 parts of walnut shells, 5 parts of eucommia leaves, 5 parts of mulberry leaves, 10 parts of watermelon peels, 5 parts of hawthorn cores, 1 part of goose not eating grass, 40 parts of seaweed, 10 parts of dragonfly grass, 400 parts of livestock and poultry manure, wherein the livesto...

Embodiment 2

[0071] A water-soluble fertilizer containing carbonase polypeptide, the raw material components and weight ratio of the water-soluble fertilizer are: 60 parts of polycarbase, 15 parts of citric acid, 200 parts of organic material extract, 30 parts of trace elements, and 45 parts of additives , 35 parts of polypeptide, 700 parts of waste liquid, 150 parts of chemical fertilizer.

[0072] The raw material components and weight ratio of the organic material extract are: 15 parts of cotton meal, 20 parts of corn germ meal, 10 parts of peanut meal, 100 parts of plant straw, 30 parts of bagasse, 20 parts of traditional Chinese medicine bagasse, edible fungus 15 parts of dregs, 10 parts of rice husks, 15 parts of walnut shells, 10 parts of eucommia leaves, 10 parts of mulberry leaves, 15 parts of watermelon peels, 10 parts of hawthorn cores, 5 parts of geese not eating grass, 80 parts of seaweed, 15 parts of dragonfly grass, 500 parts of livestock and poultry manure, wherein the live...

Embodiment 3

[0090] A water-soluble fertilizer containing carbonase polypeptide, the raw material components and weight ratio of the water-soluble fertilizer are: 50 parts of polycarbase, 12 parts of citric acid, 160 parts of organic material extract, 25 parts of trace elements, and 40 parts of additives , 30 parts of polypeptide, 600 parts of waste liquid, and 120 parts of chemical fertilizer.

[0091] The raw material components and weight ratio of the organic material extract are: 12 parts of cotton meal, 18 parts of corn germ meal, 9 parts of peanut meal, 58 parts of plant straw, 26 parts of sugar cane bagasse, 18 parts of traditional Chinese medicine bagasse, edible fungus 13 parts of slag, 9 parts of rice husk, 12 parts of walnut shell, 7 parts of Eucommia leaves, 6 parts of mulberry leaves, 12 parts of watermelon skin, 7 parts of hawthorn core, 2 parts of geese not eating grass, 60 parts of seaweed, 14 parts of dragonfly grass, 420 parts of livestock and poultry manure, wherein the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com