Biodegradable material and preparation method and application thereof

A biodegradable material and biological technology, applied in the field of medical materials, can solve the problems of slow degradation rate of L-lactic acid materials, unsatisfactory degradation rate, and limited use range, so as to improve labor productivity, increase reaction yield and product quality, and react short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The preparation of embodiment 1 biodegradable material

[0056] The mass ratio of PLLA to RAPA is 1000mg: 1.5mg;

[0057] Reagent name

M (molecular weight)

n( / mmol)

Actual value (mg)

DCC(N,N-Dicyclohexylcarbodiimide)

206.18

20e.q.,0.2 / 7

60

DMAP (4-Dimethylaminopyridine)

122.17

20e.q.,0.2 / 7

40

DCM (dichloromethane)

84.93

200mL

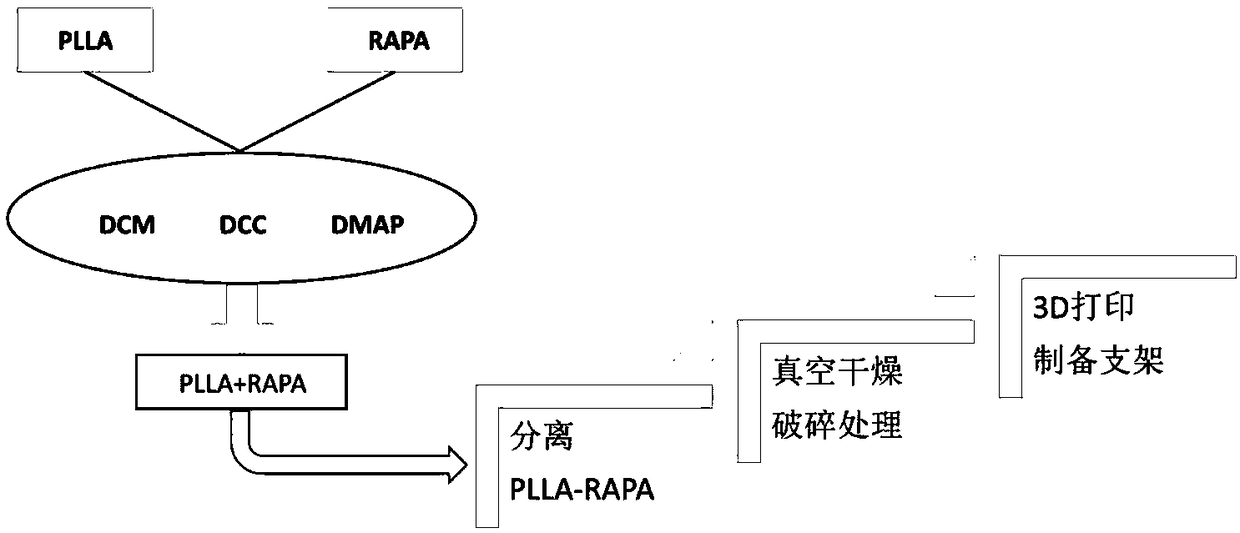

[0058] See figure 1 , add N,N-dicyclohexylcarbodiimide and 4-dimethylaminopyridine to dichloromethane according to the above ratio and mix thoroughly to obtain a reaction solution; mix PLLA and RAPA according to the above mass parts and then add it to the above preparation In the reaction solution, and then fully stirred by a rotator for 7-10 days, because dichloromethane is highly volatile and ventilation safety must be paid attention to, and sufficient stirring also makes the two substances fully mixed to achieve chain extension modification. The reaction temp...

Embodiment 2

[0060] The preparation of embodiment 2 biodegradable materials

[0061] The mass ratio of PLLA to RAPA is 1100mg: 2.5mg;

[0062]

[0063]

[0064] The specific preparation method is prepared according to the method of Example 1.

Embodiment 3

[0065] The preparation of embodiment 3 biodegradable materials

[0066] The mass ratio of PLLA to RAPA is 900mg: 1.2mg;

[0067] Reagent name

[0068] The specific preparation method is prepared according to the method of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com