Heat-insulating glass coating and preparation method thereof

A technology for insulating glass and coatings, applied in conductive coatings, reflective/signal coatings, coatings, etc., to achieve excellent antistatic properties, excellent flexibility, and excellent UV resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

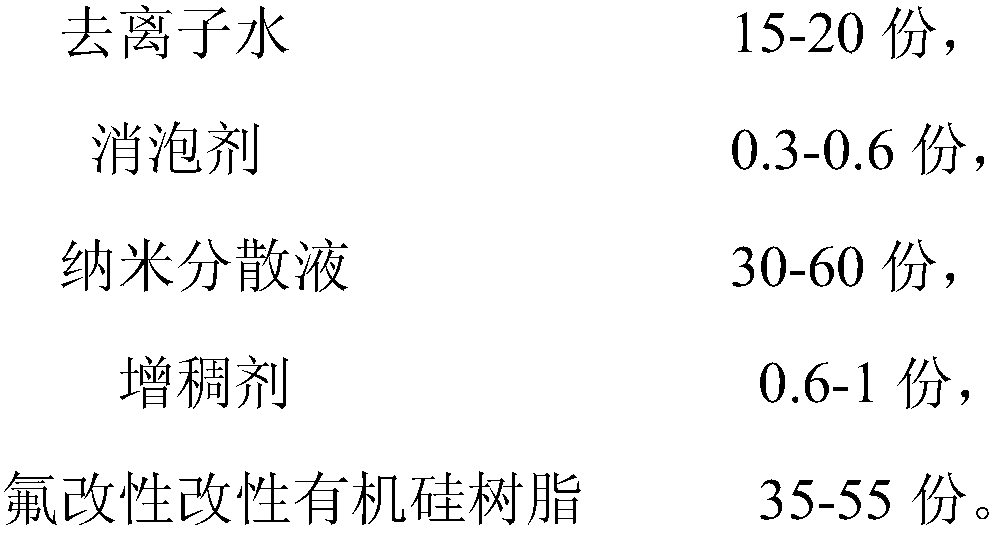

[0025] A heat-insulating glass coating invented, comprising the following components in parts by mass:

[0026]

[0027]

[0028] The defoamer is a silicone defoamer.

[0029] The fluorine-modified silicone resin is a mixture of perfluoroether allylamide and polydimethylsiloxane, and the mass ratio of the perfluoroether allylamide to polydimethylsiloxane is 0.15:0.85, the solid content of fluorine-modified silicone resin is 47%. The thickener is an alkali-swellable thickener.

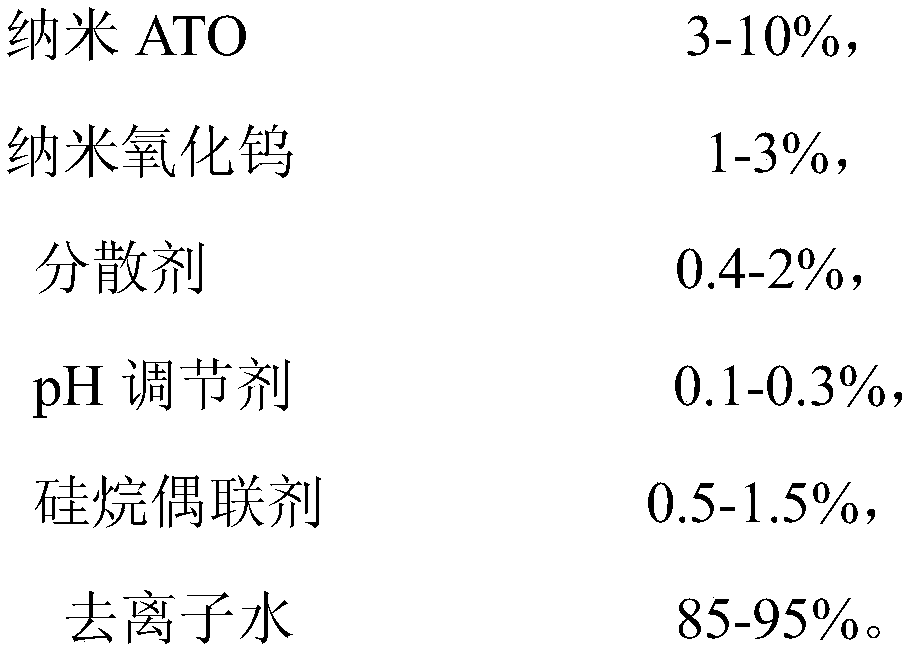

[0030] Described nano dispersion comprises the following components by mass percentage:

[0031]

[0032] The dispersant is a non-ionic dispersant; the pH regulator is 2-amino-2-methyl-1-propanol; the coupling agent is γ-aminopropyltriethoxysilane .

[0033] The preparation method of heat-insulating glass coating of the present invention, comprises the steps:

[0034] (1) Accurately weigh each component according to the parts by weight, add deionized water, add defoamer, nano-dispersion li...

Embodiment 2

[0037] The difference between embodiment 2 and embodiment 1 is:

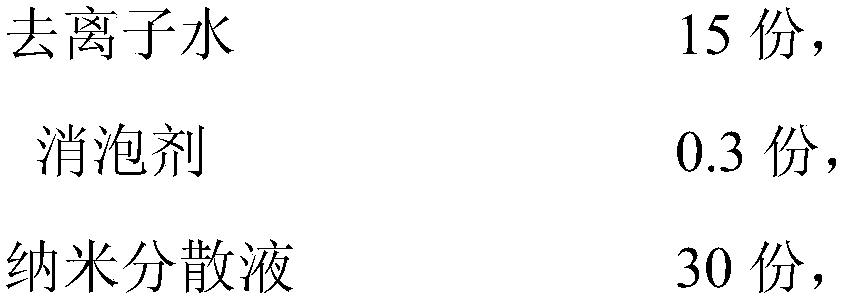

[0038] A heat-insulating glass coating of the present invention comprises the following components in parts by mass:

[0039]

[0040] The fluorine-modified silicone resin is a mixture of perfluoroether allylamide and polydimethylsiloxane, and the mass ratio of the perfluoroether allylamide to polydimethylsiloxane is 0.15:0.85, the solid content of fluorine-modified silicone resin is 44%. Described nano dispersion comprises the following components by mass percentage:

[0041]

[0042] The preparation method of heat-insulating glass coating of the present invention, comprises the steps:

[0043] (1) Accurately weigh each component according to the parts by weight, add deionized water, add defoamer, nano-dispersion liquid and fluorine-modified silicone resin according to the ratio of raw materials, and the dispersion time is 15min; in step ( 1), the preparation method of nano-dispersion liquid: accuratel...

Embodiment 3

[0046] The difference between embodiment 3 and embodiment 1 is:

[0047] A heat-insulating glass coating of the present invention comprises the following components in parts by mass:

[0048]

[0049] The solid content of the fluorine-modified silicone resin is 50%.

[0050] Described nano dispersion comprises the following components by mass percentage:

[0051]

[0052] The preparation method of heat-insulating glass coating of the present invention, comprises the steps:

[0053] (1) Accurately weigh each component according to the parts by weight, add deionized water, add defoamer, nano-dispersion liquid and fluorine-modified silicone resin according to the ratio of raw materials, and the dispersion time is 12min; in step ( 1), the preparation method of nano-dispersion liquid: accurately weigh deionized water, add dispersant, pH regulator and silane coupling agent, the dispersion time is 5min, add nano-ATO, nano-tungsten oxide and use ultrasonic dispersion to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com